Method for solid phase polypeptide synthesis of hexarelin

A technology for solid-phase polypeptide synthesis and hexarelin, which is applied in the field of preparation of solid-phase polypeptide synthesis hexarelin, can solve the problems of long synthesis cycle and use of highly toxic substances, and achieve low production cost, reduction of three wastes, and process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

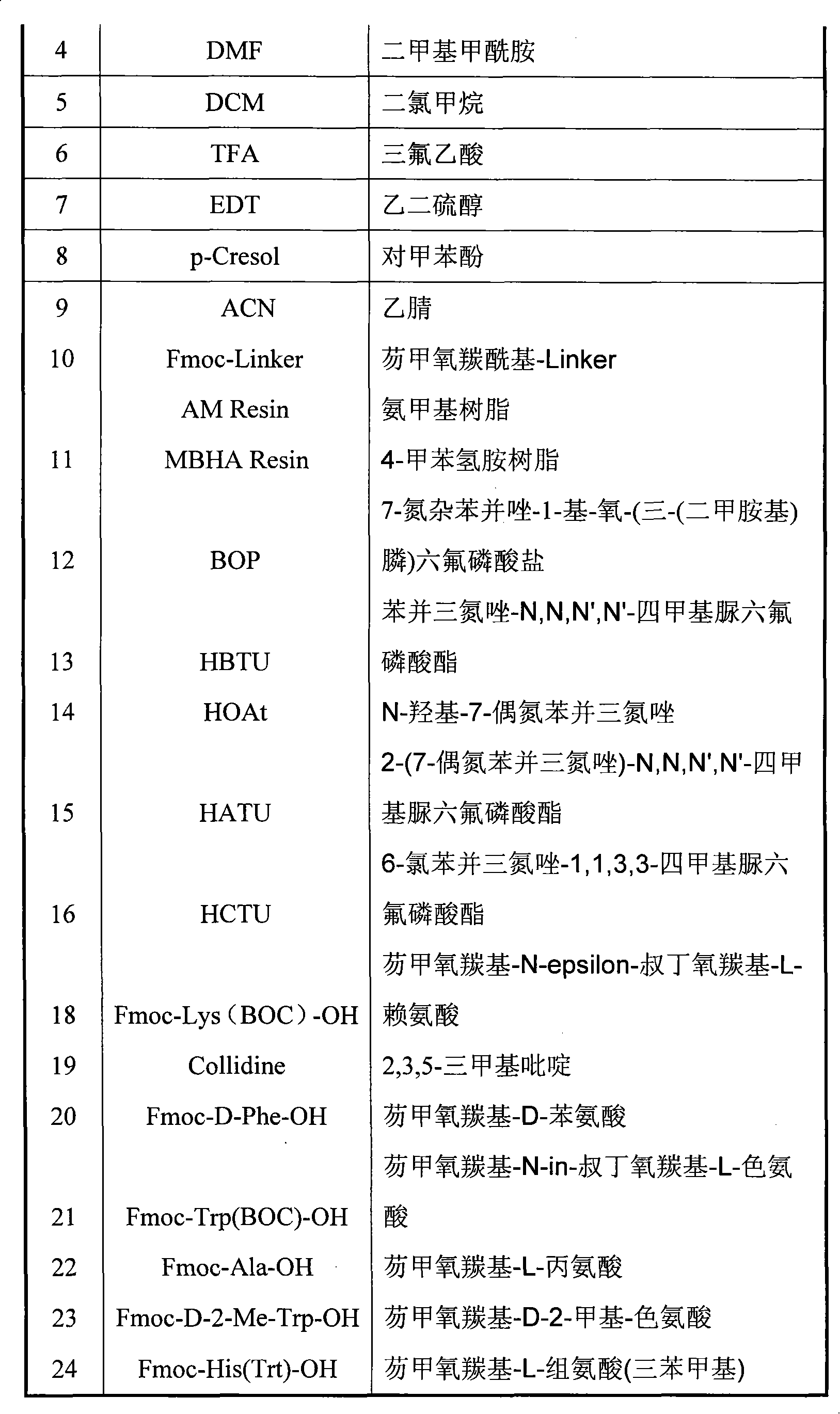

[0050] (1) Preparation of Fmoc-Lys(Boc)-Linker AM Resin

[0051] Weigh 1g of Fmoc-Linker-AM Resin (Loadding: 0.6mmol / g) into a 30ml peptide bottle, add about 15ml of DCM to the resin, soak for 10 minutes (at room temperature) and dry it with a vacuum pump, add 10ml of decapping reagent and put it in a constant temperature oscillator React for 5 minutes, dry with a vacuum pump, re-add 10ml of capping agent and react for 15 minutes (30°C-40°C), dry with a vacuum pump, wash with industrial-grade DMF for 3 times, wash with anhydrous methanol for 3 times, and re-evaporate Wash with DCM for 3 times, add Fmoc-Lys(BOC)-OH0.702g, HOBt0.337g, analytical grade DMF8ml, DIC0.2ml, Collidine0.3ml to react for 40 minutes (30℃~50℃), use vacuum pump to dry, Industrial-grade DMF was washed 3 times, anhydrous methanol was washed 3 times, redestilled DCM was washed 3 times, and dried to obtain Fmoc-Lys(Boc)-LinkerAM Resin;

[0052] (2) Preparation of Fmoc-D-Phe-Lys(Boc)-Linker AM Resin

[0053] ...

Embodiment 2

[0070] Adopt the same method and processing condition as embodiment 1, wherein:

[0071] Use Fmoc-Linker-MBHA Resin as the starting material, add decapping reagent and react at 30-50°C for 5 minutes, drain, add decapping reagent again and react for 15 minutes, wash, add Fmoc-amino acid, analytical grade DMF, Collidine, DIC / HOBt or DIC / HOAt or BOP / HOBt or BOP / HOAt or HBTU / HOBt or HBTU / HOAt or HATU / HOBt or HATU / HOAt or HCTU / HOBt or HUTC / HOAt or TBTU / HOBt, reaction 40 minutes, with embodiment 1 Operate until the hexapeptide is finished. After cutting and other reactions, 0.540 g of white powder product was obtained.

Embodiment 3

[0073]Weigh 50g of Fmoc-Linker-AM Resin or Fmoc-Linker-MBHA Resin (Loadding: 0.7mmol / g) and pour it into a 600ml peptide bottle, add the decapping reagent at 30-50°C for 5 minutes, drain it, and add the decapping reagent again for 15 minutes min, wash, add Fmoc-amino acid, analytical grade DMF, Collidine, DIC / HOBt or DIC / HOAt or BOP / HOBt or BOP / HOAt or HBTU / HOBt or HBTU / HOAt or HATU / HOBt or HATU / HOAt or HCTU / HOBt or TBTU / HOBt, react for 40 minutes, operate with embodiment 1, until the hexapeptide is connected. After cutting and other reactions, 33g of white powder product was obtained. The purity of the crude product reacted with HBTU / HOBt will be better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com