Integrated flexible sensor based on sandwich type spinning film and manufacturing method

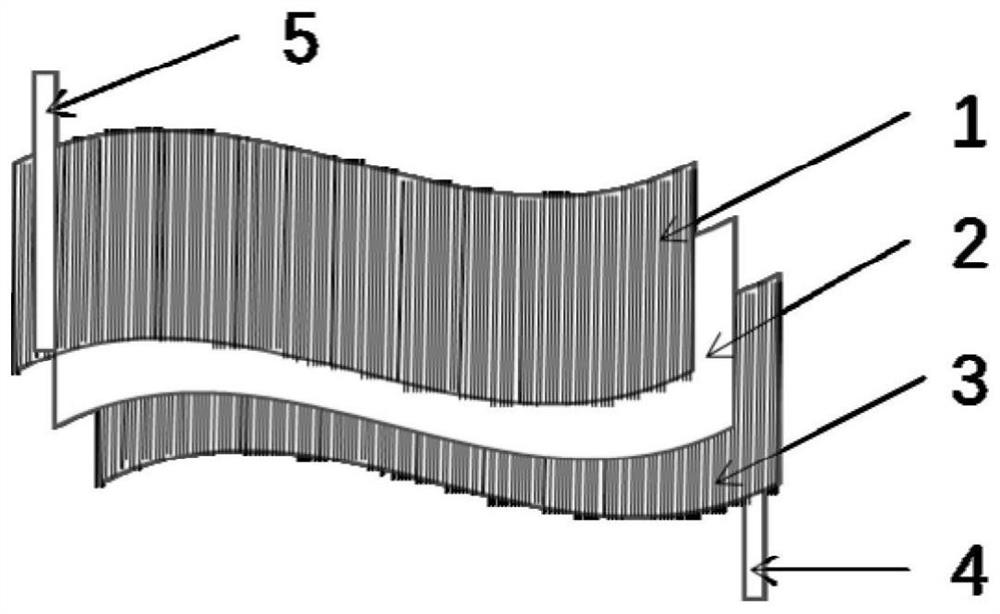

A flexible sensor, sandwich-type technology, applied in nanotechnology for sensing, transmission of sensing components using electromagnetic/magnetic devices, nanotechnology, etc., can solve the complex preparation process, poor conductivity, and poor mechanical properties of the sensor and other problems, to achieve the effect of simple process, low equipment requirements, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

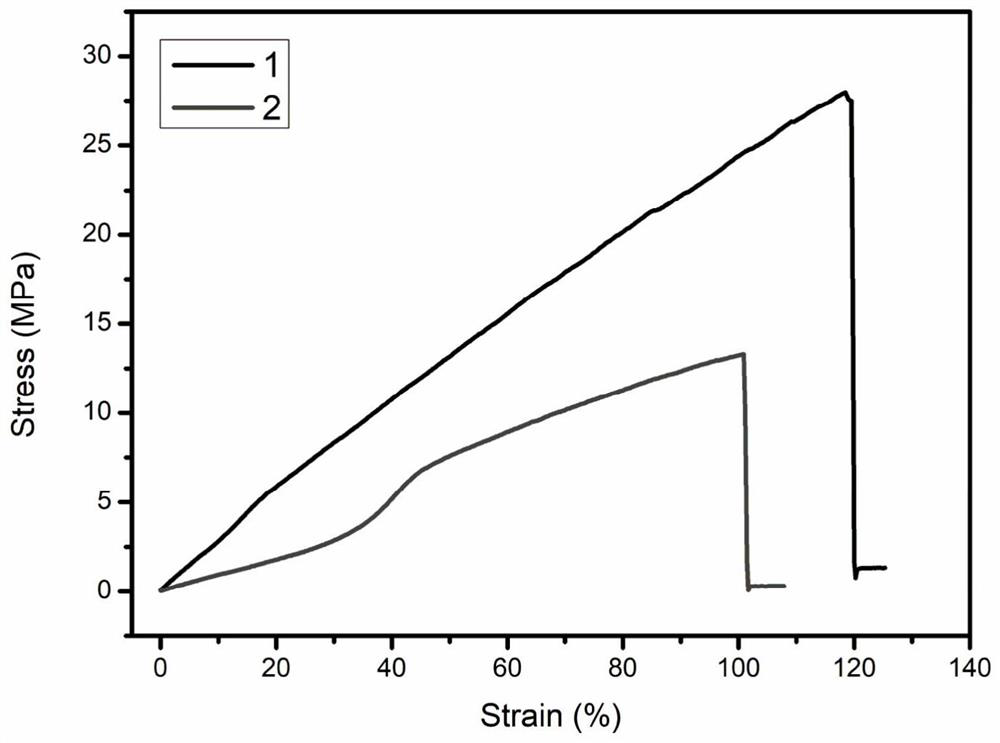

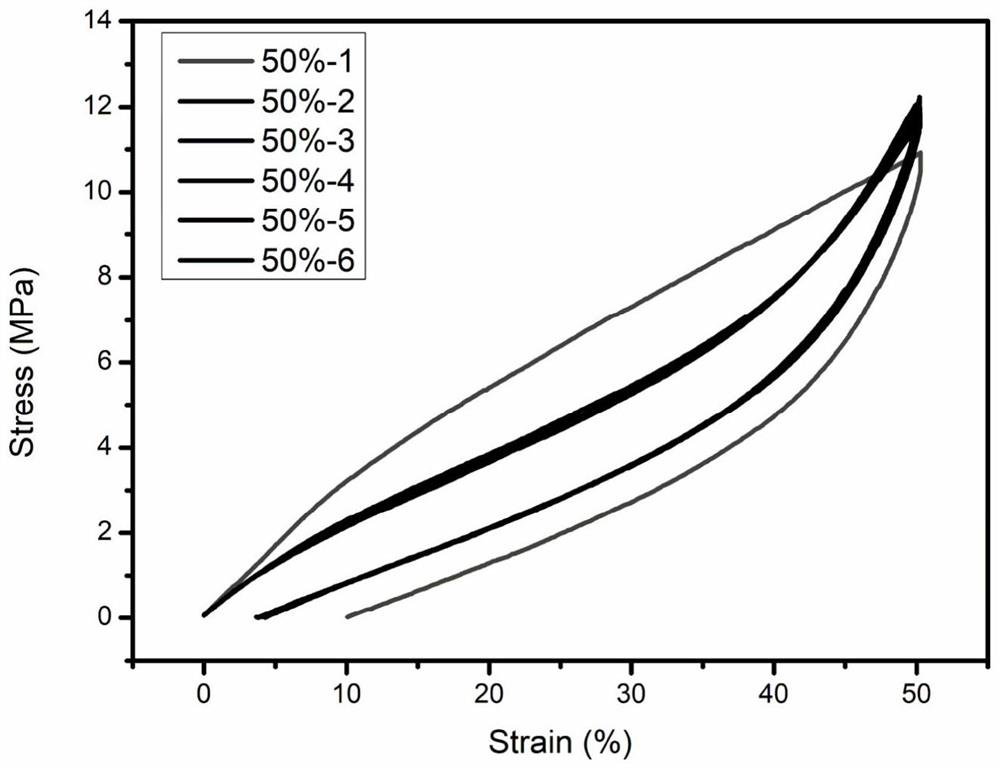

Examples

preparation example Construction

[0032] The invention is a method for preparing an integrated flexible sensor, comprising the following steps:

[0033] (1) Preparation of few-layer MXene and silver nanowires: two conductive components were prepared by acid etching method and hydrothermal method, respectively.

[0034] (2) Preparation of flexible matrix liquid: use tetrahydrofuran (THF) and dimethyl sulfoxide (DMSO) with a volume ratio of 1:1 to 1.5:1 as the dissolution medium, and the flexible matrix material is thermoplastic polyurethane (TPU), polylactic acid (PLA), polycaprolactone (PCL), etc., were stirred at 55° C. for 3 hours to obtain a flexible matrix liquid with a mass fraction of 12%-14%.

[0035](3) Preparation of the spinning precursor suspension: firstly, the dimethyl sulfoxide (DMSO)-alcohol mixed system with a volume ratio of 1:0.01-1:0.05 was used as the dispersion medium, and the MXene and silver nanowires were mixed and ground, and then Mix with a dispersant and ultrasonicate for 2 hours at...

Embodiment 1

[0037] Example 1: Preparation of an integrated flexible sensor

[0038] (1) Preparation of few-layer MXene and silver nanowires

[0039] First prepare few-layer MXene, add 1g lithium fluoride to 10mL 9mol / L hydrochloric acid solution, then slowly add 1gTi 3 AlC 2 Powder (3 C 2 T x or Ti 3 C 2 T x clay. Then prepare silver nanowires, add 5ml 0.02M AgNO3 and 5ml 0.02M NaCl into 30ml distilled water, stir to form AgCl colloid, then dissolve 0.04g 0.2mol glucose in the above colloid solution, and move it into the hydrothermal synthesis reaction kettle , kept in a heating furnace at 180°C for 18 hours, cooled to room temperature in the air, filtered and placed in a vacuum dryer (30°C) for 3 hours, and rinsed with alcohol to remove the silver precipitate (silver nanowires).

[0040] (2) Preparation of flexible matrix liquid

[0041] Tetrahydrofuran (DHF) and dimethyl sulfoxide (DMSO) were used to form a mixed solvent system at a volume ratio of 1:1, and 2.4 g of TPU was add...

Embodiment 2

[0047] Example 2: Preparation of an integrated flexible sensor

[0048] (1) Preparation of few-layer MXene and silver nanowires

[0049] First prepare few-layer MXene, add 1g lithium fluoride to 10mL 9mol / L hydrochloric acid solution, then slowly add 1gTi 3 AlC 2 Powder (3 C 2 T x or Ti 3 C 2 T x clay. Then prepare silver nanowires, add 5ml 0.02M AgNO3 and 5ml 0.02M NaCl into 30ml distilled water, stir to form AgCl colloid, then dissolve 0.04g 0.2mol glucose in the above colloid solution, and move it into the hydrothermal synthesis reaction kettle , kept in a heating furnace at 180°C for 18 hours, cooled to room temperature in the air, filtered and placed in a vacuum dryer (30°C) for 3 hours, and rinsed with alcohol to remove the silver precipitate (silver nanowires).

[0050] (2) Preparation of flexible matrix liquid

[0051] Tetrahydrofuran (DHF) and dimethyl sulfoxide (DMSO) were used to form a mixed solvent system with a volume ratio of 1.2:1, and 2.4g of PCL was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com