Beta-cyclodextrin modified mesoporous silica ball-polymer hybrid proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and mesoporous silicon spheres, which is applied in the treatment of dyed organosilicon compounds, dyed polymer organic compounds, fibrous fillers, etc., can solve the problem of low proton conductivity of composite proton exchange membranes, limitations of performance improvement of proton exchange membranes, Problems such as agglomeration of inorganic components, to achieve the effect of improved proton conductivity, good industrial production basis, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

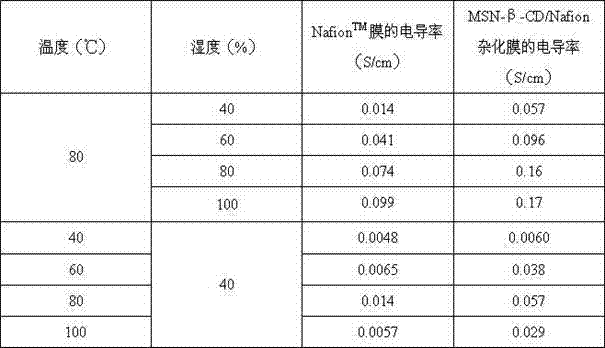

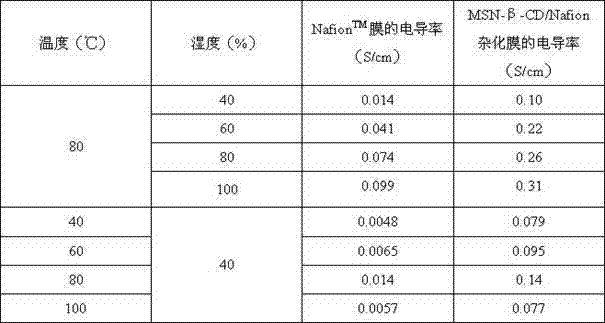

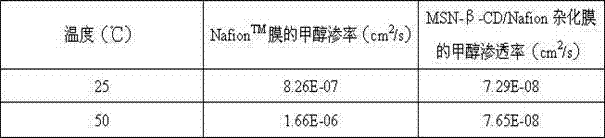

Embodiment 1

[0030] (1) Preparation of β-cyclodextrin-modified mesoporous silica spheres: Disperse 0.5 g of mesoporous silica spheres in 300 ml of toluene, add 2 mL of (3-mercaptopropyl)-trimethoxysilane, and react at 120 °C 3h. Subsequently, the mercapto-modified mesoporous silicon spheres were obtained by centrifugation, washed with ethanol several times, and dried. Next, dissolve 0.03 g of mercapto-modified mesoporous silica spheres in 30 mL of H 2 O aqueous solution, add 0.25g 6-carbon primary hydroxyl monop-toluenesulfonyl β-cyclodextrin ester. At 80°C, select a power of 200 W, microwave reaction for 20 minutes, use acetone as a precipitant, centrifuge, wash with ethanol, and dry to obtain β-cyclodextrin modified mesoporous silica spheres;

[0031] (2) Preparation of β-cyclodextrin modified mesoporous silica sphere-polymer hybrid proton exchange membrane: Take 4 ml of commercially available Nafion TM Solution, remove about half of the solvent by rotary evaporation, add 2.5 ml N,N-d...

Embodiment 2

[0039] (1) Preparation of β-cyclodextrin-modified mesoporous silica spheres: Disperse 0.5 g of mesoporous silica spheres in 300 ml of toluene, add 2 mL of (3-mercaptopropyl)-trimethoxysilane, and react at 120 °C 3h. Subsequently, the mercapto-modified mesoporous silicon spheres were obtained by centrifugation, washed with ethanol several times, and dried. Next, dissolve 0.03 g of mercapto-modified mesoporous silica spheres in 30 mL of H 2 O aqueous solution, add 0.25g 6-carbon primary hydroxyl monop-toluenesulfonyl β-cyclodextrin ester. At 80°C, select a power of 200 W, microwave reaction for 20 minutes, use acetone as a precipitant, centrifuge, wash with ethanol, and dry to obtain β-cyclodextrin modified mesoporous silica spheres;

[0040] (2) Preparation of β-cyclodextrin modified mesoporous silica sphere-polymer hybrid proton exchange membrane: Take 4 ml of commercially available Nafion TM Solution, after about half of the solvent was removed by rotary evaporation, 2.5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com