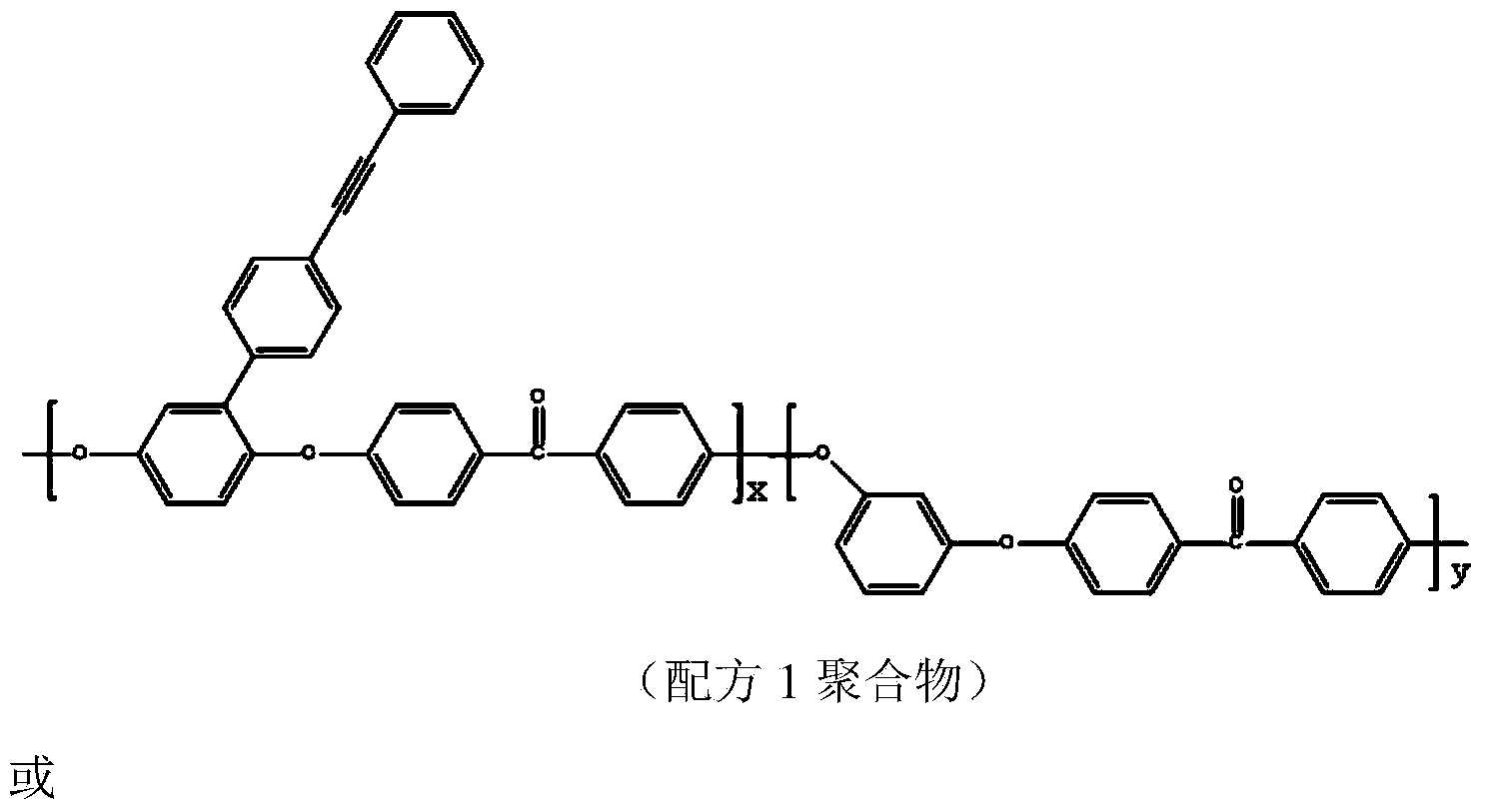

Polyether-ether-ketone polymer carbon fiber composite material containing phenylacetylene side group and preparation method thereof

A polyether ether ketone and composite material technology is applied in the field of polyether ether ketone polymer carbon fiber composite material and its preparation, which can solve the problems of high equipment process conditions and difficult composite materials, and achieves easy control of the production process and production. The effect of easy equipment and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Arrange the continuous carbon fiber (that is, Mitsubishi Rayon Grafil TR50S carbon fiber) on the arrangement machine.

[0041] 2. Then immerse the continuous carbon fiber in the molar ratio of resorcinol: 4-phenylacetylene phenylhydroquinone: 4-4'difluorobenzophenone is 0.4:0.6:1, and the viscosity is 76mpa*s 1 In the glue solution, set the parameters of the prepreg arranging machine to the traction tension of 5N and the traction speed of 10m / min to start routing.

[0042] 3. Remove the carbon fiber / polymer prepreg collected by the collection roller and place it in a cool place to dry. The resin content of the obtained prepreg is 32.1 wt%, the impregnation is good, and the surface is smooth and even. see figure 1 Photo.

[0043] 4. Cut the prepared carbon fiber / polymer prepreg tape into a suitable size, and put it into a mold for hot pressing. The hot-pressing parameters are as follows: first raise the temperature to 240°C, melt for 15 minutes, then raise the tem...

Embodiment 2

[0045] The glue solution in the embodiment 1 step 2 is changed to the polymerization molar ratio and is hydroquinone: 4-phenylacetylene phenylhydroquinone: 4-4' difluorobenzophenone is 0.8: 0.2: 1, and the viscosity is For the formula 2 glue of 66mpa*s, the remaining processes in steps 1, 2, and 3 are consistent with embodiment 1. The resin content of gained prepreg is 28.2wt%, impregnation is good, and the surface is smooth and level (see figure 2 Photo). Step 4 is to put the prepared carbon fiber / polymer prepreg tape into a mold for thermocompression molding. The hot-pressing parameters are as follows: first raise the temperature to 240°C, melt for 15 minutes, pressurize to 0.6 MPa, raise the temperature to 370°C, keep constant pressure and temperature for 1 hour, and take out the sample after natural cooling.

Embodiment 3

[0047] All the other are consistent with embodiment 1 except following processing conditions. The glue solution in the embodiment 1 step 2 is changed to a polymerization molar ratio of resorcinol: 4-phenylacetylene phenylhydroquinone: 4-4' difluorobenzophenone is 0.1: 0.9: 1, and the viscosity is Formula 1 glue of 90mpa*s. The resin content of the obtained prepreg is 36.5 wt%, the impregnation is good, and the surface is smooth and even. The prepared carbon fiber / polymer prepreg tape is put into a mold for thermocompression molding. The hot-pressing parameters are as follows: first raise the temperature to 230°C, melt for 15 minutes, pressurize to 0.6 MPa, raise the temperature to 350°C, keep constant pressure and temperature for 1 hour, and take out the sample after natural cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com