A kind of preparation method of sintering flux for iron ore sintering

A technology for sintering flux and iron ore, which is applied in the field of metallurgical engineering, can solve the problems of increasing slag system and increasing the burden of slag discharge of enterprises, and achieves the effects of improving strength, improving reducibility and strength, and increasing reduction output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

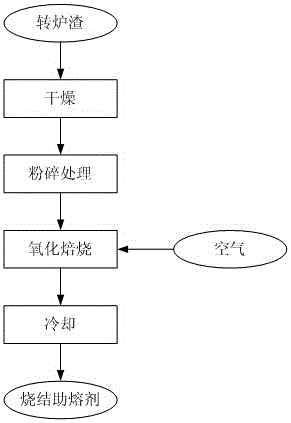

[0025] The flow process of the sintering flux preparation method for iron ore sintering of the present invention is as follows figure 1 As shown, it specifically includes the following steps:

[0026] A) The converter slag is dried at 120° C., and then pulverized into a powder. It is required that the particles with a particle size of -100 mesh in the powder account for more than 85% of the total weight of the powder.

[0027] It is required that particles with a particle size of -100 mesh account for more than 85% of the total weight of the powder in order to ensure that the converter slag powder can more fully react with oxygen during the subsequent oxidation roasting process.

[0028] B) The converter slag powder obtained in the previous step is oxidized and roasted in the air at a temperature of 800-1100° C., and kept at the roasting temperature for 1-2 hours.

[0029] In the process of oxidizing and roasting converter slag, the reaction (1) occurs when the temperature is...

Embodiment 1

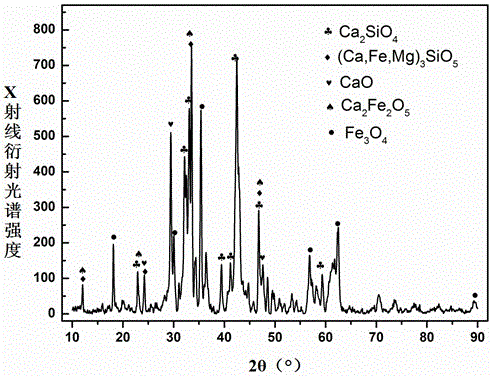

[0046] The main composition of the converter slag produced by steelmaking used in this embodiment is shown in Table 1, wherein the mass percentage of CaO accounts for 40.21%, SiO 2 The mass percentage of TFe accounts for 14.69%, the mass percentage of TFe accounts for 18.44%, Al 2 o 3 The mass percentage accounts for 2.40%. The XRD pattern (X-ray diffraction pattern) of this converter slag is as follows figure 2 , where θ is the Bragg diffraction angle.

[0047] Table 1 Chemical composition of converter slag (wt%)

[0048]

[0049] Using the converter slag as a raw material, the sintering flux is prepared by oxidizing and roasting through the preparation method of the present invention, and the specific process is as follows:

[0050] The converter slag is dried at 120°C and crushed into powder, the particle size of which is -100 mesh in the powder accounts for more than 85% of the total weight of the powder; then, the converter slag powder is oxidized and roasted in t...

Embodiment 2

[0053] In this embodiment, the converter slag shown in Table 1 is used. Among its main components, the mass percentage of CaO accounts for 40.21%, SiO 2 The mass percentage of TFe accounts for 14.69%, the mass percentage of TFe accounts for 18.44%, Al 2 o 3 The mass percentage accounts for 2.40%. Using the converter slag as a raw material, the sintering flux is prepared by oxidizing and roasting through the preparation method of the present invention, and the specific process is as follows:

[0054] The converter slag is dried at 120°C and crushed into powder. The particles with a particle size of -100 mesh in the powder account for more than 85% of the total weight of the powder; then, the converter slag powder is oxidized and roasted at 900°C in air, And keep the temperature at the calcination temperature for 1-2 hours; after calcination, the obtained product is naturally cooled to room temperature to obtain the sintering flux product.

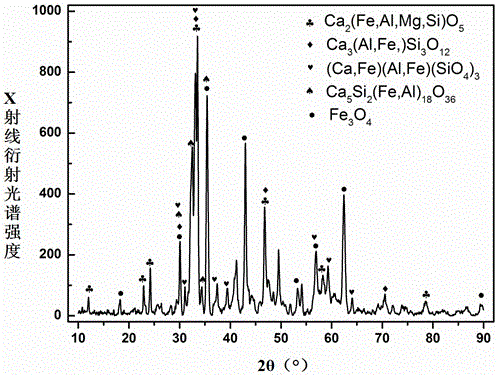

[0055] The resulting sintering flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com