Anti-alcohol tea and preparation method thereof

A kind of anti-alcohol tea, 1-5% technology, applied in the field of functional tea, can solve the problems of bad taste, side effects, difficult to swallow, etc., and achieve the effect of excellent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

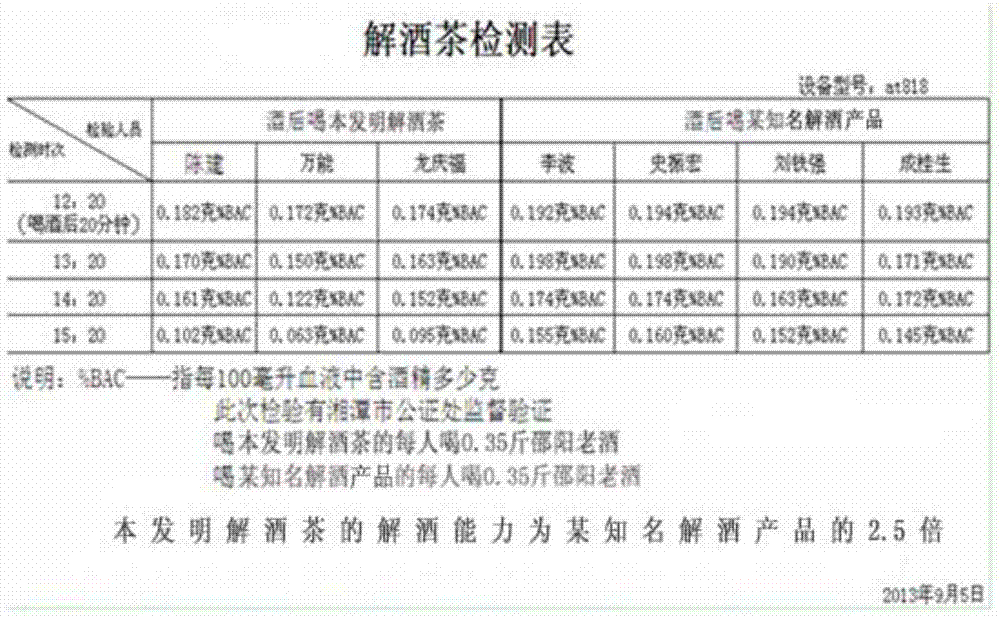

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Firstly, Pueraria root, lotus leaf, Huoxiang, Stevia, Luo Han Guo, Galangal, Hovenia dulcis, honeysuckle, licorice, sealwort, hawthorn, malt, tangerine peel and other raw materials are first coarsely crushed by a crusher and crushed to about 1 mesh ;

[0053] Then press Pueraria 38%, lotus leaf 18%, Huoxiang 5%, Stevia 4%, Luo Han Guo 2%, Galangal 4%, Hovenia dulcis 8%, Honeysuckle 5%, Licorice 5%, Polygonatum 3%, Hawthorn 2 %, 4% of malt, 2% of tangerine peel by weight, respectively weighing and preparing the coarsely crushed raw materials;

[0054] Send the prepared coarse powder raw materials into the YTH150 mixer for mixing, the mixing time is 20 minutes, and fully mix;

[0055] Put the mixed raw materials into an oven for drying, the drying temperature is 60°C, and the drying time is 180 minutes;

[0056] Put the dried and cooled raw materials into the TY-30L superfine pulverizer, use 6 powerful refrigerators to cool down the super powder tank to -17°C, let it pu...

Embodiment 2

[0062] Firstly, Pueraria root, lotus leaf, Huoxiang, stevia, Luo Han Guo, galangal, Hovenia dulcis, honeysuckle, licorice, sealwort, hawthorn, malt, tangerine peel and other raw materials are first coarsely crushed by a crusher, and crushed to about 3 mesh ;

[0063] Then press Pueraria 35%, lotus leaf 12%, Huoxiang 10%, Stevia 8%, Luo Han Guo 2%, Galangal 3%, Hovenia dulcis 5%, Honeysuckle 4%, Licorice 5%, Polygonatum 4%, Hawthorn 4 %, malt 5%, tangerine peel 3% by weight, the coarsely crushed raw materials are weighed and prepared respectively;

[0064] Send the prepared coarse powder raw materials into the YTH150 mixer for mixing, the mixing time is 30 minutes, and fully mix;

[0065] Put the mixed raw materials into an oven for drying, the drying temperature is 50°C, and the drying time is 200 minutes;

[0066] Put the dried and cooled raw materials into the TY-30L superfine pulverizer, use 6 powerful refrigerators to cool down the super powder tank to -17°C, let it pulv...

Embodiment 3

[0072] Firstly, Pueraria root, lotus leaf, Huoxiang, Stevia, Luo Han Guo, Galangal, Hovenia dulcis, honeysuckle, licorice, sealwort, hawthorn, malt, tangerine peel and other raw materials are first coarsely crushed by a crusher and crushed to about 5 mesh ;

[0073] Then press Pueraria 40%, Lotus Leaf 20%, Huoxiang 4%, Stevia 5%, Mangosteen 4%, Galangal 2%, Hovenia dulcis 10%, Honeysuckle 2%, Licorice 1%, Polygonatum 2%, Hawthorn 2 %, malt 3%, tangerine peel 5% by weight, the coarsely crushed raw materials are weighed and prepared respectively;

[0074] Send the prepared coarse powder raw materials into the YTH150 mixer for mixing, the mixing time is 40 minutes, and fully mix;

[0075] Put the mixed raw materials into an oven for drying, the drying temperature is 70°C, and the drying time is 150 minutes;

[0076] Put the dried and cooled raw materials into the TY-30L superfine pulverizer, use 6 powerful refrigerators to cool down the super powder tank to -17°C, let it pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com