Ulva juice products containing ulva oligosaccharide and preparation method thereof

A technology of Ulva oligosaccharides and Ulva juice, which is applied in the field of biotechnology and food, can solve the problems of poor market competitiveness, low added value, low utilization rate of raw material nutrients, etc., and reduce viscosity and gelling , enhance the taste and nutrition, increase the effect of cell permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

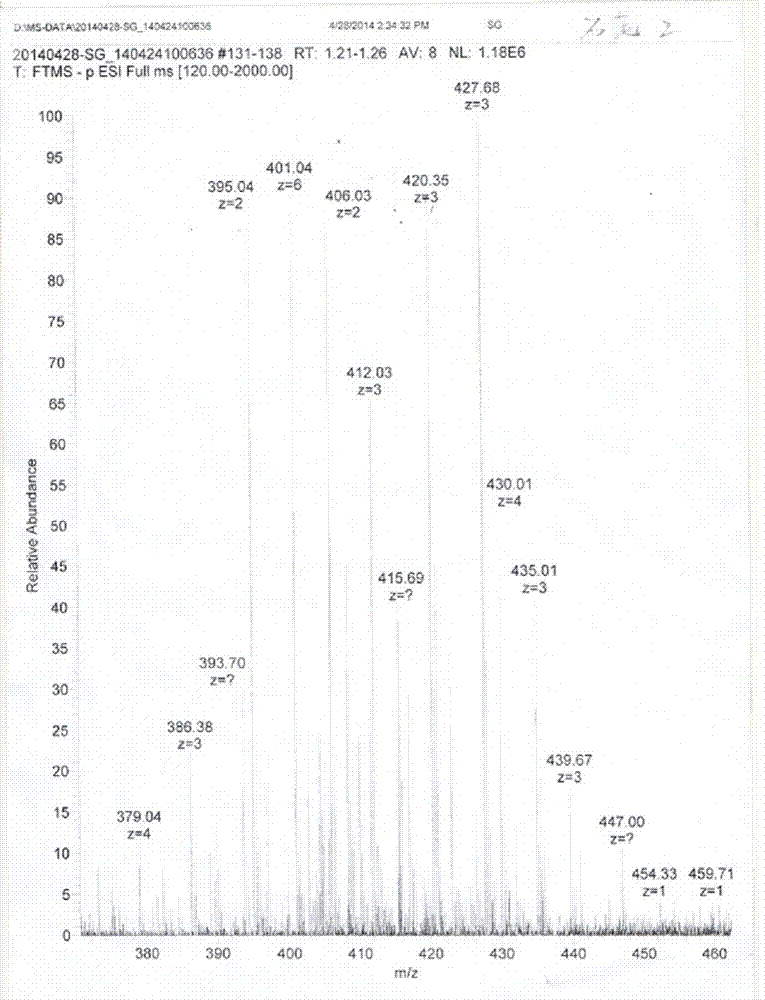

Image

Examples

Embodiment 1

[0016] Take 100 g of Ulva powder, add 5000 mL of water, heat to 100 °C, keep stirring for 1 h, cool to room temperature, keep warm at 30 °C for 30 min, add 1 g of sulfate ester polysaccharide degrading enzyme, stir well, and put it in a constant temperature of 30 °C Enzymolysis in the box for 6.5 h. Stir continuously during the reaction to make the enzymatic hydrolysis fully proceed. After 6.5 h of reaction, the enzymatic hydrolysis reaction was terminated by boiling. The enzymatically hydrolyzed Ulva solution was centrifuged at 4000 rpm for 10 min, and the supernatant was taken, which was Ulva raw juice prepared by enzymatic hydrolysis. The reducing sugar content was measured to be greater than 0.583 mg / mL, that is, per gram of Ulva dry powder can be obtained The content of Ulva oligosaccharides was more than 27.984 mg. Divide the raw Ulva juice prepared above into two parts on average, one part is evaporated and concentrated about 20 times under reduced pressure at 55oC to...

Embodiment 2

[0018] Take 100 g of Ulva powder, add 2000 mL of water, heat to 100 °C, keep stirring for 1 h, cool to room temperature, keep warm at 30 °C for 30 min, add 1 g of sulfate ester polysaccharide degrading enzyme (purchased from sigma company), stir well, and placed in a 30°C incubator for enzymatic hydrolysis for 6.5 h. Stir continuously during the reaction to make the enzymatic hydrolysis fully proceed. After 6.5 h of reaction, the enzymatic hydrolysis reaction was terminated by boiling. The enzymatically hydrolyzed Ulva solution was centrifuged at 4000 rpm for 10 min, and the supernatant was taken, which was the Ulva juice prepared by enzymatic hydrolysis. Its reducing sugar content is measured to be greater than 1.3 mg / mL, that is, the amount of Ulva oligosaccharides that can be obtained per gram of Ulva dry powder is greater than 25 mg. Divide the Ulva juice prepared above into two parts on average, one part is evaporated and concentrated about 12 times under reduced pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com