Tobacco plasticizer and application thereof

A plasticizer, tobacco technology, applied in the application, tobacco, smoke oil filter and other directions, can solve problems such as lack, and achieve the effect of reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Making filter sticks

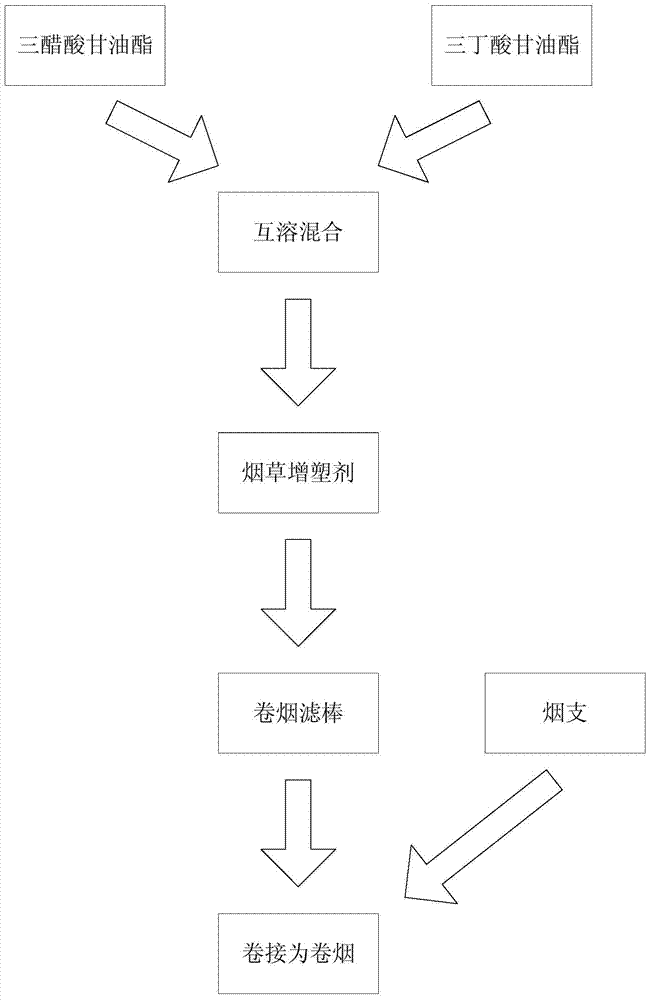

[0035] Triacetin and tributyrin are mixed and stirred at a ratio of 50%:50% by weight (5:5 by weight), and then added to the cigarette in an amount of 8% by weight of the cigarette filter rod In the filter rod processing technology, it is used as a mixed plasticizer 1 in the processing of cigarette acetate filter rods; at the same time, only 8% triacetin is added to the cigarette filter rod processing technology in the weight percentage of cigarette filter rods, and it is used as cigarette acetate filter rods. Control plasticizers in rod processing. Among them, the filter rod design parameters are shown in Table 1.

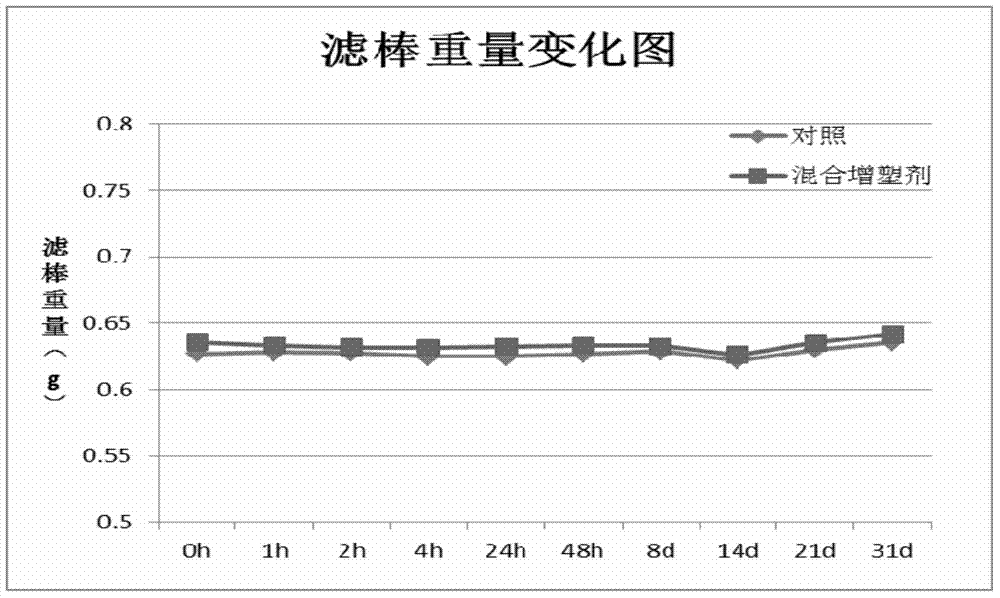

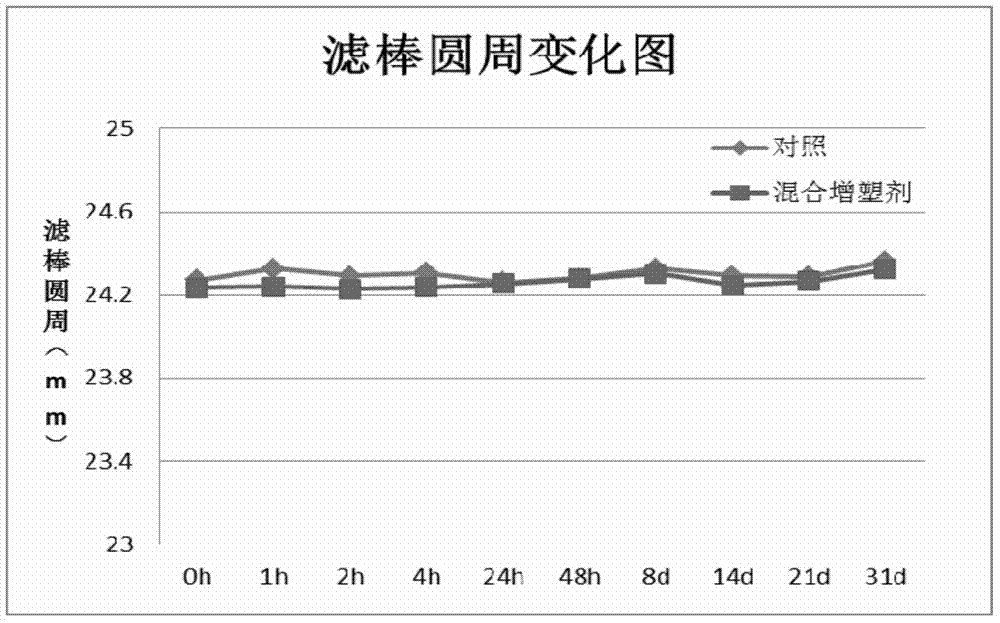

[0036] Follow up and measure the filter sticks made by adding mixed plasticizer 1 and the filter sticks added with the control plasticizer, at 1 hour, 2 hours, 4 hours, 24 hours, 48 hours, 8th day, 14th day, On the 21st day and the 31st day, the changes in the filter rod weight, circumference, and pressure drop were measured re...

Embodiment 2

[0045] 1. Making filter sticks

[0046] Glyceryl triacetate and glyceryl tributyrate are miscibly mixed and stirred at a weight percentage of 40%:60% (weight ratio 4:6) and 60%:40% (weight ratio 6:4) to account for 10% by weight of cigarette filter rods is added to the cigarette filter rod processing technology, respectively as mixed plasticizers 2 and 3 in the processing of cigarette acetate filter rods; at the same time, only 10% by weight of cigarette filter rods is added Glyceryl triacetate was added into the processing technology of cigarette filter rods as a control plasticizer in the processing of cigarette acetate filter rods. Among them, the filter rod design parameters are shown in Table 3.

[0047] Table 3 Design parameters of filter rods

[0048] serial number

[0049] Follow-up measurements were made on the filter sticks made with mixed plasticizers 2 and 3 and the filter sticks added with the control plasticizer, at 1 hour, 2 hours, 4 hours, 24 hours,...

Embodiment 3

[0056] 1. Making filter sticks

[0057] Filter sticks with mixed plasticizer 1 and control plasticizer were prepared as in Example 1, and the design parameters of the filter sticks are shown in Table 1.

[0058] 2. Tobacco Industry Harm Index Evaluation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com