Simple method for preparing compound adsorbing material by straws and coal gangues together

A technology of composite adsorption material and coal gangue is applied in the field of resource utilization of solid waste, which can solve the problems of polluting the surrounding environment, encroaching on land and farmland, destroying land resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Select crop straw and coal gangue as raw materials, first obtain powdery materials with a certain particle size range through drying, crushing and screening respectively (the size of straw and coal gangue are both 250um); then according to the mixing mass ratio of straw and coal gangue is 60 :40 the two are uniformly mixed, put into a crucible and compacted, and carry out calcining treatment in a muffle furnace (the treatment system is to heat up at a heating rate of 12°C / min, to be kept at 600°C for 40min, and at 850°C for 60min), namely Obtain the finished composite adsorbent material.

[0021] The composite adsorption material prepared in this example was tested for adsorption performance. Under the condition of magnetic stirring, 25 mg of composite adsorbent material was added into methylene blue solution (50 mL, 0.03 g / L), stirred for 15 min, centrifuged and filtered, and the supernatant was taken for absorbance test. Utilize the ultraviolet-visible spectrophotome...

Embodiment 2

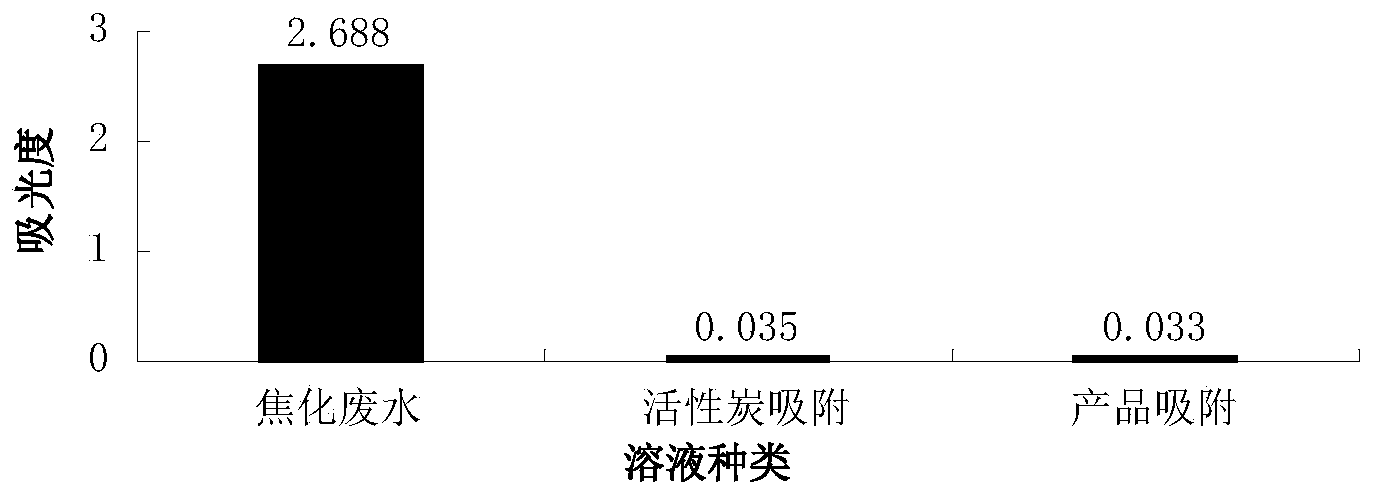

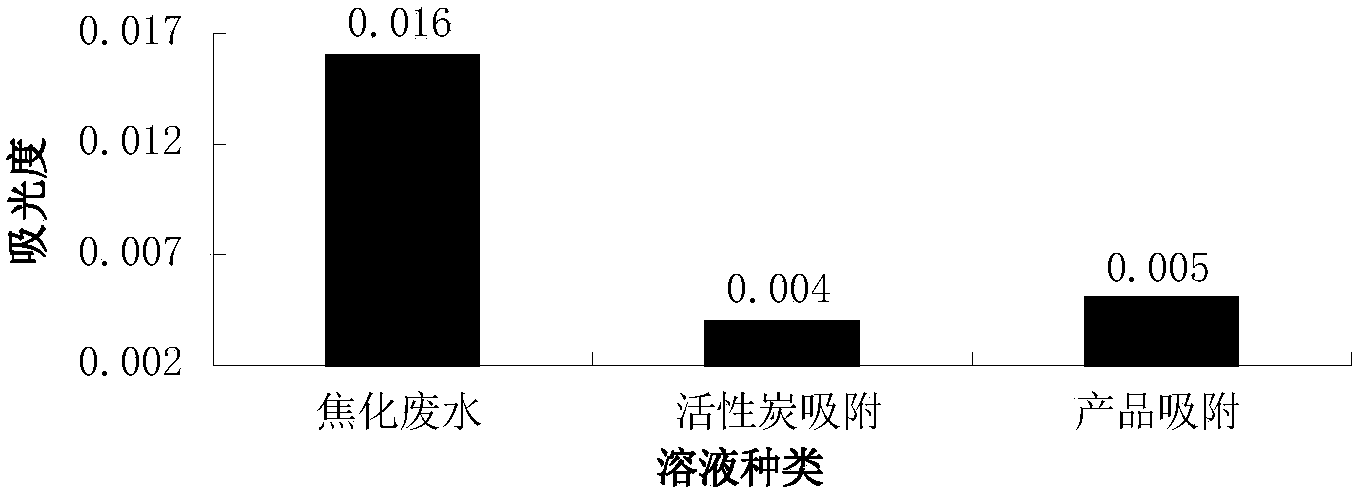

[0023] Select crop straw and coal gangue as raw materials, first obtain powdery materials with a certain particle size range (the size of straw is 250um, and the size of coal gangue is 75um) through drying, crushing, and screening respectively; then according to the mixing mass ratio of straw and coal gangue Mix the two evenly at a ratio of 90:10, put them into a crucible and compact them, and perform calcination in a muffle furnace (the treatment system is to heat up at a heating rate of 15°C / min, keep at 500°C for 35min, and hold at 800°C for 70min) , that is, the finished composite adsorbent material is obtained. The absorbance of the composite adsorption material prepared in this example is 2.688 before being used to treat the methylene blue solution, and the absorbance of the methylene blue solution after being treated is 0.041.

Embodiment 3

[0025] Select crop straw and coal gangue as raw materials, first obtain powdery materials with a certain particle size range (the size of straw is 150um, and the size of coal gangue is 75um) through drying, crushing, and screening respectively; then according to the mixing mass ratio of straw and coal gangue Mix the two evenly at a ratio of 75:25, put them into a crucible and compact them, and perform calcination in a muffle furnace (the treatment system is to heat up at a heating rate of 15°C / min, keep at 500°C for 30min, and hold at 815°C for 60min) , that is, the finished composite adsorbent material is obtained.

[0026] The absorbance of the composite adsorption material prepared in this example is 2.688 before being used to treat the methylene blue solution, and the absorbance of the methylene blue solution after being treated is 0.033.

[0027] The microscopic morphology of the composite adsorbent material prepared in Example 3 of the present invention is as follows: f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com