Air-exhaust port sealing structure and manufacturing method thereof

A technology of sealing structure and air extraction port, which is used in manufacturing tools, glass molding, glass remolding, etc., can solve the problems of weakening the air tightness of solder performance, not necessarily good economic benefits, complicated vacuuming process, etc. Long service life, simple structure and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

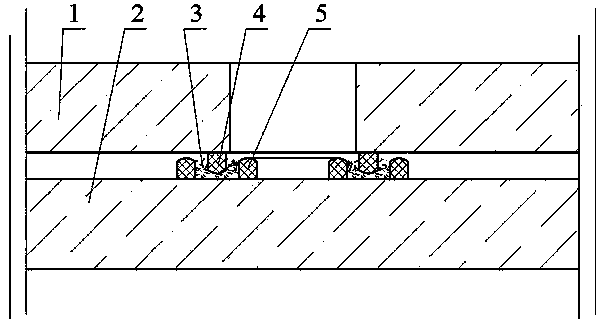

[0059] Embodiment 1: see figure 1 , the vacuum glass is composed of upper glass 1 and lower glass 2, a through hole is drilled on the upper glass 1 to form an air inlet, and the glass is coated or printed on the lower surface of the upper glass 1 and the upper surface of the lower glass 2. Paste or metal paste printing are respectively made into an upper insert 4 and two lower joints 5 concentric with the air inlet, the upper insert 4 of the upper glass 1 can be inserted between the two lower joints 5 of the lower glass 2, and the upper There is an air extraction channel between the insert 4 and the lower joint 5; send the upper and lower glasses into a high-temperature furnace or tempering furnace to sinter the upper insert 4 and the lower joint 5 on the upper and lower glass, and then use low-temperature glass solder in the normal-pressure high-temperature furnace In the middle, edge sealing is carried out on the upper and lower glass after assembling. After the glass after ...

Embodiment 2

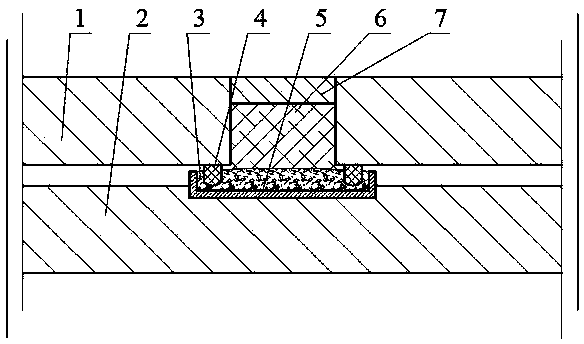

[0060] Example 2: see figure 2 , the vacuum glass is made up of upper glass 1 and lower glass 2, on the upper glass 1, a through hole with a large upper opening and a smaller lower opening is drilled to form an air extraction port, and a metal or glass tube with an edge is prepared as the upper insert 4, the upper The edge of the insert 4 and the upper glass 1 are welded together by glass solder or metal paste, and the top of the upper insert 4 is lower than the upper surface of the upper glass 1; a metal or glass tube with a bottom is prepared as the lower joint 5, and the lower Connector 5 and upper insert 4 are connected together or directly placed on the lower glass or placed in the pit on the lower glass; when upper insert 4 adopts a metal tube, preferably a metal with a thermal expansion coefficient close to the glass such as Kovar alloy, the upper insert 4 and When the lower joint 5 adopts glass tube, it is preferable to apply metal paste at the junction to strengthen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com