Energy-saving and production-increasing method and device adopting low temperature methanol cleaning technology

A low-temperature methanol washing and methanol technology, applied in the petroleum industry, sustainable manufacturing/processing, combustible gas purification, etc., can solve the problems of high methanol concentration, low concentration and high methanol consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

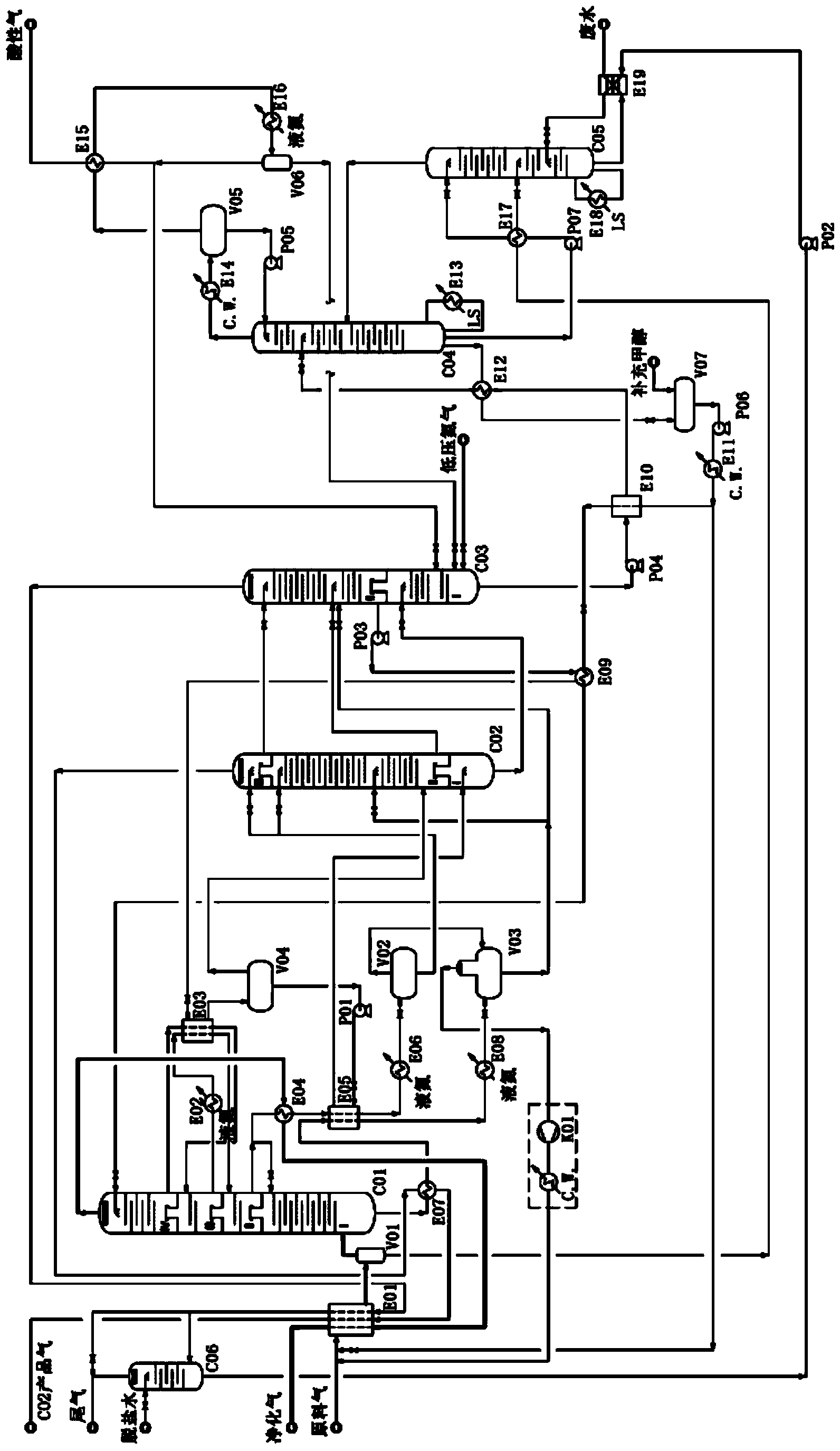

[0080] Embodiment 1 adopts as attached figure 2 process shown. (with CO 2 product tower)

[0081] The low-temperature methanol washing device shown in the figure includes tail gas scrubber C06, raw gas separator V01, absorption tower C01, cycle gas compressor K01, methanol-rich medium-pressure flash tank V02, sulfur-containing methanol medium-pressure flash tank V03, Circulating methanol flash tank V04, flash methanol pump P01, CO 2 Product tower C02, H2S concentration tower C03, circulating methanol pump P03, H2S concentration tower bottom pump P04, thermal regeneration reflux pump P05, lean methanol pump P06, methanol collection tank V07, thermal regeneration tower C04, thermal regeneration reflux tank V05, acid gas Separator V06, methanol water tower reboiler E18, waste water heat exchanger E19, feed gas cooler E01, circulating methanol ammonia cooler E02, circulating methanol heat exchanger E03, purified gas / rich methanol heat exchanger E04, rich methanol exchanger He...

Embodiment 2

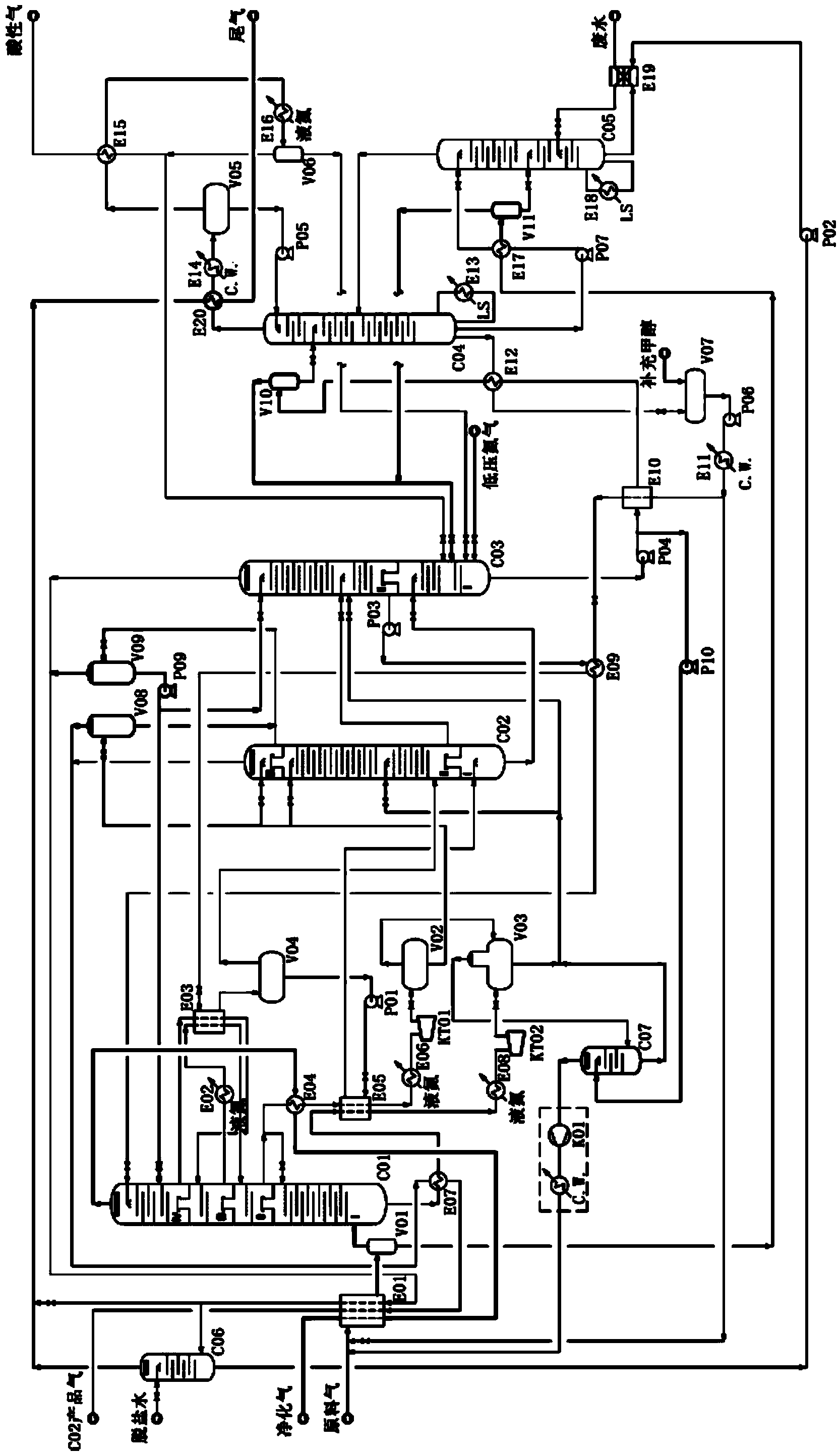

[0102] Embodiment 2 adopts as attached image 3 process shown. (without CO2 product column)

[0103] The low-temperature methanol washing device shown in the figure includes tail gas scrubber C06, raw gas separator V01, absorption tower C01, cycle gas compressor K01, methanol-rich medium-pressure flash tank V02, sulfur-containing methanol medium-pressure flash tank V03, Circulating methanol flash tank V04, flash methanol pump P01, H2S concentration tower C03, circulation methanol pump P03, H2S concentration tower bottom pump P04, thermal regeneration reflux pump P05, lean methanol pump P06, methanol collection tank V07, thermal regeneration tower C04 , Thermal regeneration reflux tank V05, acid gas separator V06, methanol water tower reboiler E18, waste water heat exchanger E19, feed gas cooler E01, circulating methanol ammonia cooler E02, circulating methanol heat exchanger E03, purified gas / rich Methanol heat exchanger E04, methanol-rich heat exchanger E05, methanol-rich a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com