Method for recycling platinum group metals from iron carrier invalid automobile exhaust catalyst

A technology of automobile exhaust and platinum group metals, applied in the direction of improving process efficiency, etc., can solve problems such as by-product pollution, achieve the effects of reducing the emission of three wastes, less consumption, and convenient absorption and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

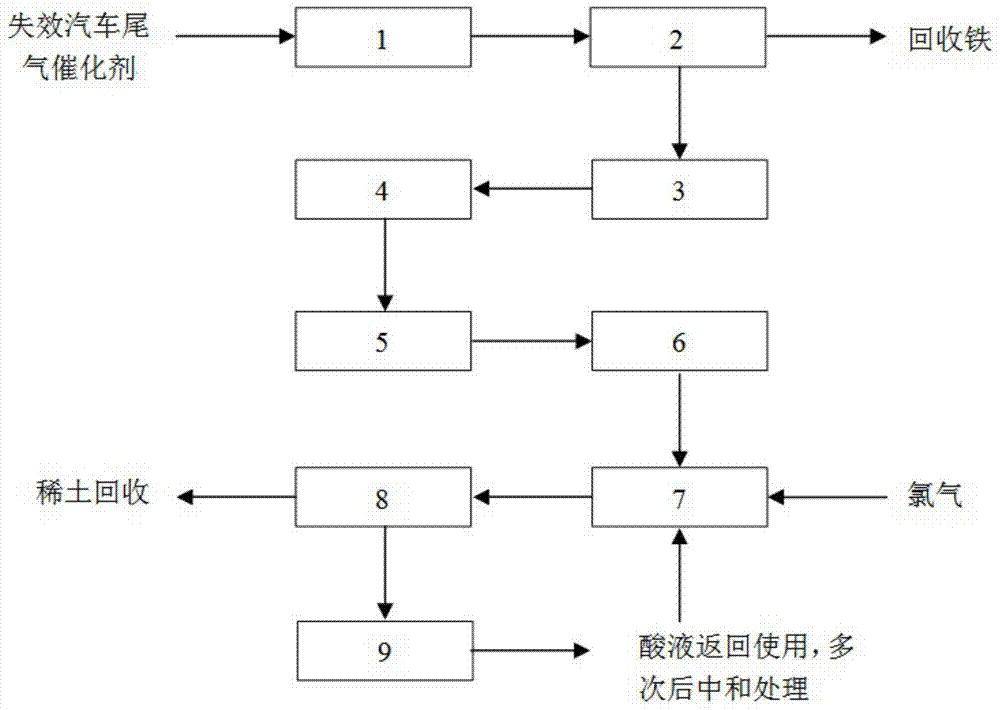

Method used

Image

Examples

Embodiment 1

[0018] 1) Crush the expired catalyst until the size of the broken iron sheet is about 10x10mm, and collect the powder particles generated during the crushing process.

[0019] 2) Put the powder particles collected during the crushing process together with the crushed fragments into an ultrasonic cleaning machine for ultrasonic separation, react for 2 hours, remove the iron sheet from the machine and clean its surface with water, the cleaned liquid and ultrasonic The liquid in the washing machine is combined and filtered.

[0020] 3) Put the filtered residue in an oven for 5 hours at 110° C., then put the dried solid in a muffle furnace at 1400° C. for 16 hours. After the muffle furnace cools down, take the solid out and cool it to room temperature.

[0021] 4) Add the calcined solid into a pulverizer for pulverization, and all pulverized powders pass through a 100-mesh standard sieve.

[0022] 5) Add the powder into a reaction kettle equipped with stirring, a thermometer and ...

Embodiment 2

[0026] 1) Crush the expired catalyst until the size of the broken iron sheet is about 25x25mm, and collect the powder particles generated during the crushing process.

[0027] 2) Put the powder particles collected during the crushing process together with the crushed fragments into an ultrasonic cleaning machine for ultrasonic separation, react for 5 hours, remove the iron sheet from the machine and clean its surface with water, the cleaned liquid and ultrasonic The liquid in the washing machine is combined and filtered.

[0028] 3) Put the filtered residue in an oven to dry at 130°C for 2h, then put the dried solid in a muffle furnace at 1100°C for 22h, and take out the solid after the muffle furnace cools down and cool it down to room temperature.

[0029] 4) Put the calcined solid into a pulverizer for pulverization, and all pulverized powders pass through a 200-mesh standard sieve.

[0030] 5) Add the powder into a reaction kettle equipped with stirring, a thermometer and...

Embodiment 3

[0034] (1) Crush the invalid catalyst until the size of the broken iron sheet is about 40x40mm, and collect the powder particles generated during the crushing process.

[0035] (2) Put the powder particles collected during the crushing process together with the crushed fragments into an ultrasonic cleaning machine for ultrasonic separation, react for 8 hours, remove the iron sheet from the machine and clean its surface with water, the cleaned liquid and The liquid in the ultrasonic cleaner is combined and filtered.

[0036] (3) Put the filtered residue into an oven to dry at 120°C for 5h, then put the dried solid into a muffle furnace for 3h at 1500°C, and take out the solid to cool to room temperature after the muffle furnace cools down.

[0037] (4) Add the calcined solid into a pulverizer for pulverization, and all pulverized powders pass through a 400-mesh standard sieve.

[0038] (5) Add the powder into a reaction kettle equipped with stirring, a thermometer and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com