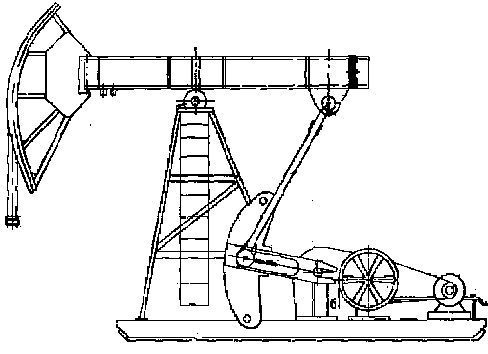

Oil pumping unit at mouth of well

A pumping unit and sucker rod technology, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve problems such as low belt transmission efficiency, achieve safe and reliable motor operation, overcome difficulties in parameter adjustment, and reduce The effect of small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

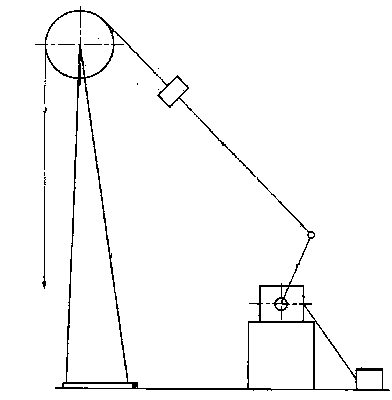

[0030] In order to overcome the low efficiency of the belt drive of the existing pumping unit and the insufficient problems of the three-phase asynchronous motor used as the power of the pumping unit, this embodiment provides a Figure 5 The wellhead pumping unit shown includes a sucker rod 4, a switched reluctance motor 1, a rotary table 2, an eccentric shaft 3 and a motor control box 6;

[0031] One end of the switched reluctance motor 1 is electrically connected to the motor control box 6, and the other end is connected to the turntable 2 through a linkage shaft. The turntable 2 is provided with an eccentric shaft 3, and the sucker rod 4 is connected to the eccentric shaft 3.

[0032] The switched reluctance motor 1 and the turntable 2 are supported on the ground by brackets; the eccentric shaft 3 is flexibly connected to the turntable 2, and the sucker rod 4 realizes different strokes through different suspension positions on the turntable 2. The stopped rotation drives th...

Embodiment 2

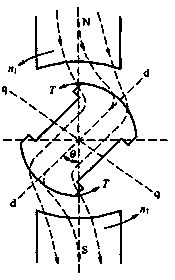

[0039] On the basis of Embodiment 1, the motor control box 6 is composed of a microcomputer, an energy-saving control module, and a power converter, and the energy-saving control module and the power converter are respectively electrically connected to the microcomputer. The motor control box 6 is used to control the continuous operation of the switched reluctance motor 1. Its specific working principle is as follows: the microcomputer comprehensively processes the speed command, the speed feedback signal and controls the main switching device in the power converter through the feedback information of the position sensor. On and off to realize the control of the running state of the switched reluctance motor 1 . According to the speed feedback signal, the energy-saving control module runs the intelligent speed regulation algorithm, analyzes and calculates the optimal operation, forms a control strategy, and generates operation instructions. The power converter controls the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com