Fireproof insulated cable

A technology of insulating cables and insulating layers, which is applied to insulated cables, power cables, insulated conductors, etc., can solve the problems of poor electrical performance and safety performance of cables, and achieve the effects of good mechanical shock resistance, improved insulation performance, and good water spray performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

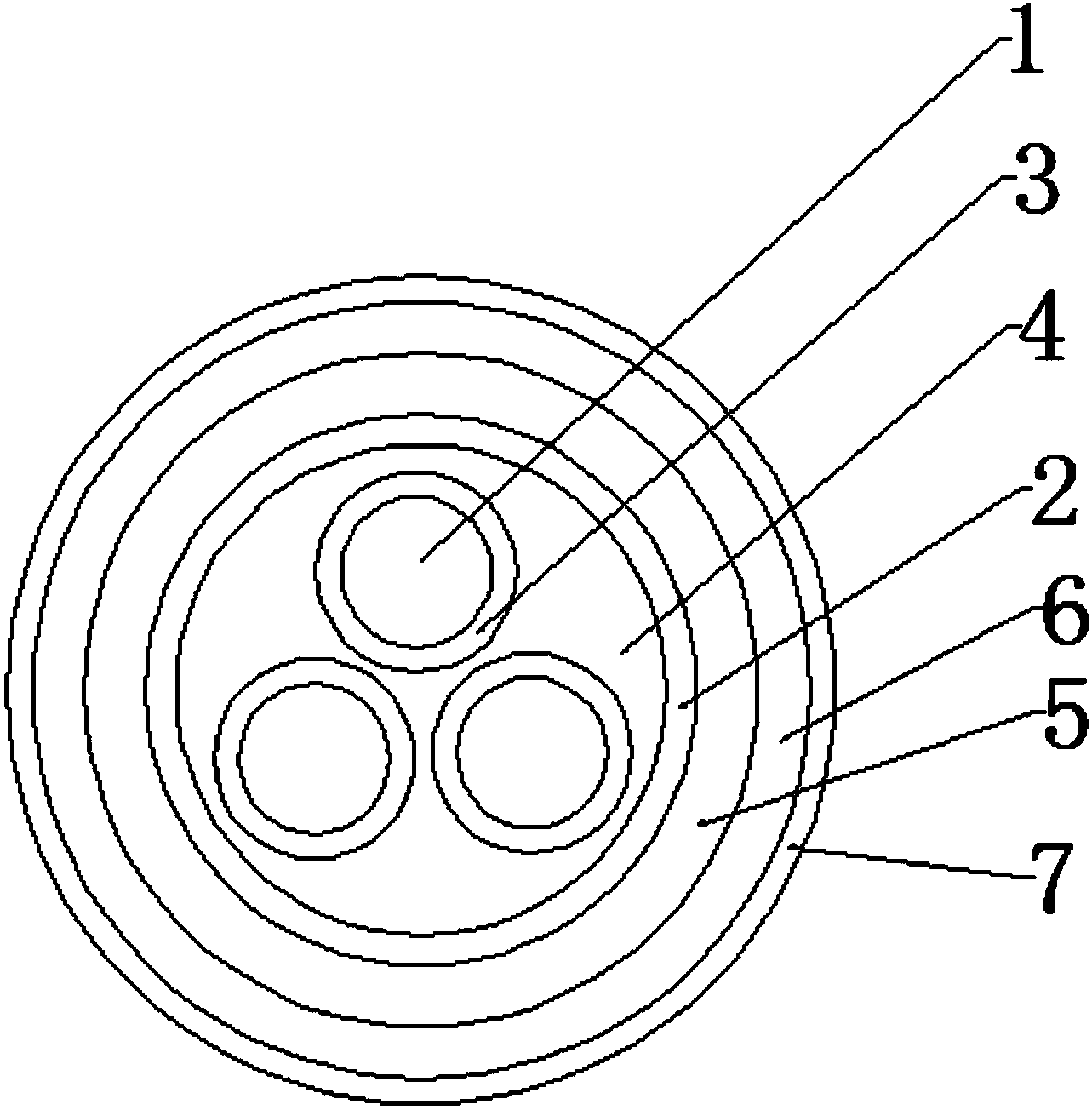

[0015] Such as figure 1 As shown, it is a fireproof insulated cable of this embodiment, which includes at least one conductor 1, the conductor 1 is covered with a first insulating layer 3, and the three conductors covered with the first insulating layer 3 are all covered In the ceramic short fiber layer 2, between the first insulating layer 3 and the first insulating layer 3 and between the first insulating layer 3 and the ceramic short fiber layer 2, magnesium oxide mineral insulating powder 4 is arranged, and the ceramic short fiber layer 2 Copper sheath 5, second insulating layer 6 and fireproof layer 7 are coated on the outside in turn; fireproof layer 7 is made of the following raw materials according to weight percentage: 40% inorganic base material, 30% environmentally friendly flame retardant, 20% organic polymer material and 10% fireproof pigment.

[0016] The ceramic short fiber layer is used to cover the wire. The ceramic short fiber material has good insulation pe...

Embodiment 2

[0020] A fireproof insulated cable of this embodiment differs from Embodiment 1 in that the fireproof layer 7 is made of the following raw materials by weight percentage: 50% inorganic base material, 20% environmentally friendly flame retardant, 20% organic polymer material and 10% fireproof pigment.

[0021] The organic polymer is halogen-containing resin, the first insulating layer 3 is braided by ceramic short fibers; the second insulating layer 6 is epoxy ester insulating varnish, and the fireproof pigment is aluminum pigment.

Embodiment 3

[0023] A fireproof insulated cable of this embodiment differs from Embodiment 1 in that: the fireproof layer 7 is made of the following raw materials by weight percentage, 30% inorganic base material, 35% environmentally friendly flame retardant, 30% organic polymer material and 5% fireproof pigment; the first insulating layer 3 is extruded from short ceramic fibers; the second insulating layer 6 is polyamide composite paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com