A kind of roger substrate double-sided reflow soldering method

A reflow soldering and substrate technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of difficult glue dispensing, device working point drift, and difficult heat conduction, etc., and achieves advanced and reasonable welding methods, reliable welding quality, and high The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

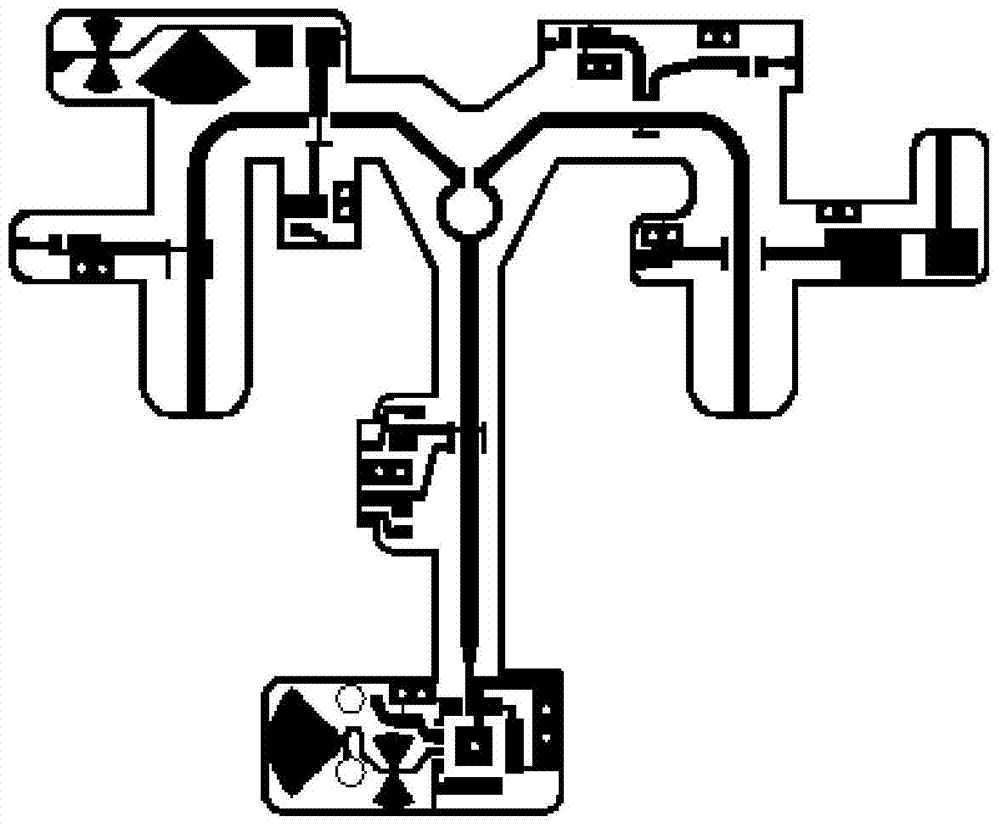

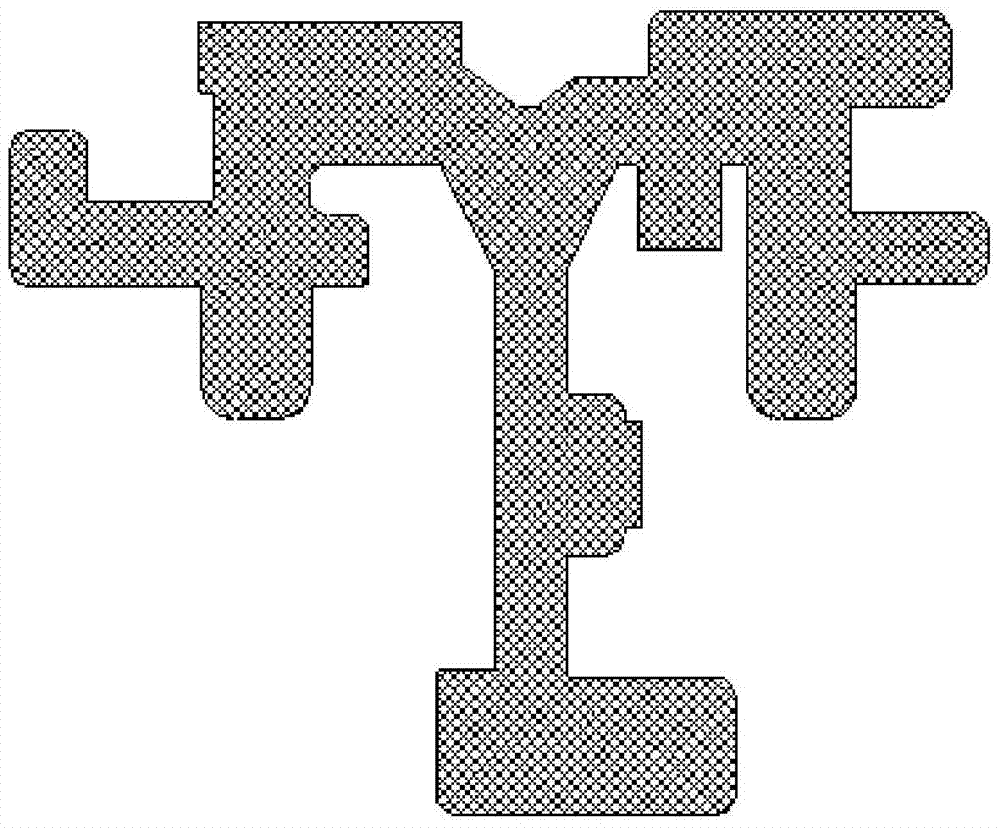

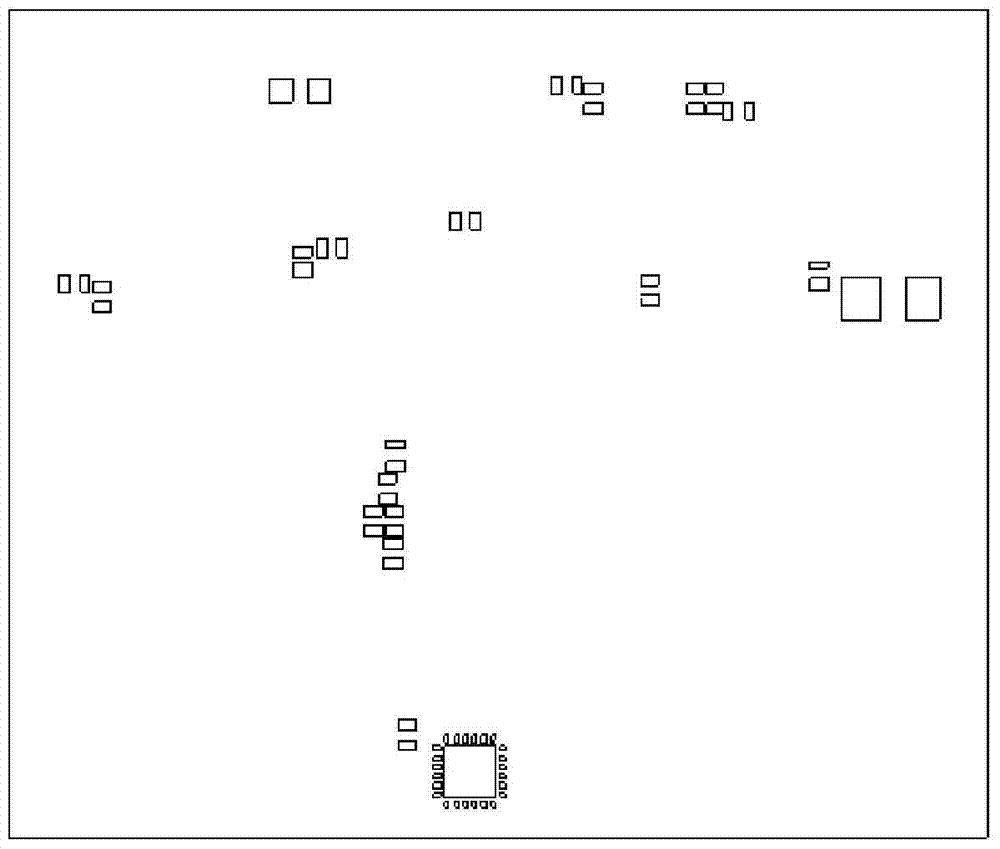

[0025] Such as Figure 4 , 5 , 6, a Roger substrate double-sided reflow soldering method described in the embodiment of the present invention, the soldering method includes the following steps: first cleaning and drying the cavity and the substrate; applying the processed solder paste Printing on the substrate; placing the chip on the coated substrate for mounting; reflow soldering the mounted chip. Stencil and load design, the stencil mainly prints solder paste for the substrate, a substrate has two stencils, the top stencil and the bottom stencil. The bottom stencil mainly prints solder paste on the bottom of the substrate, and the top stencil mainly prints solder paste on the top of the substrate. The size of the stencil should be compatible with the size of the substrate, and the bottom stencil should be designed with grids to make the gas generated during reflow soldering easy to discharge. The thickness of the substrate is only 0.254mm. During reflow soldering, the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com