Production line for wheat aleurone layer content cooked flour

A wheat aleurone layer and content technology, which is applied in the fields of mechanical manufacturing design and production line design, can solve problems such as difficult to grasp the taste and difficult temperature control, and achieve the effects of good taste, product safety and hygiene, and simple production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

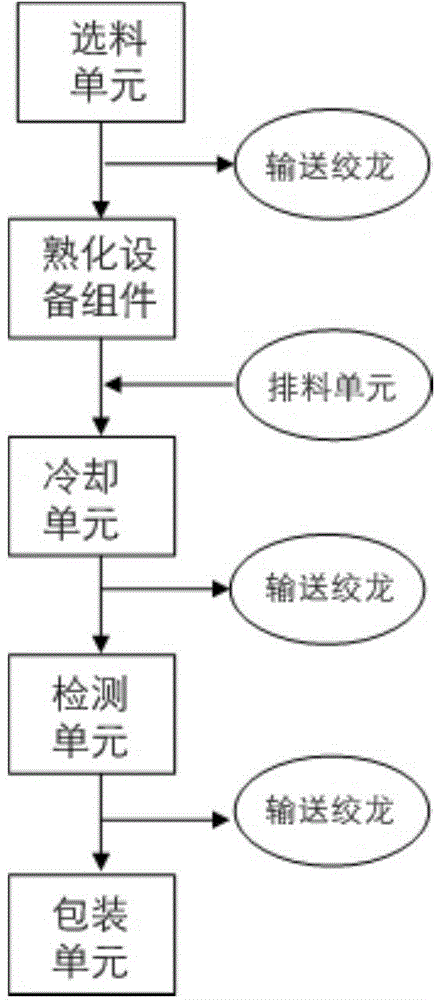

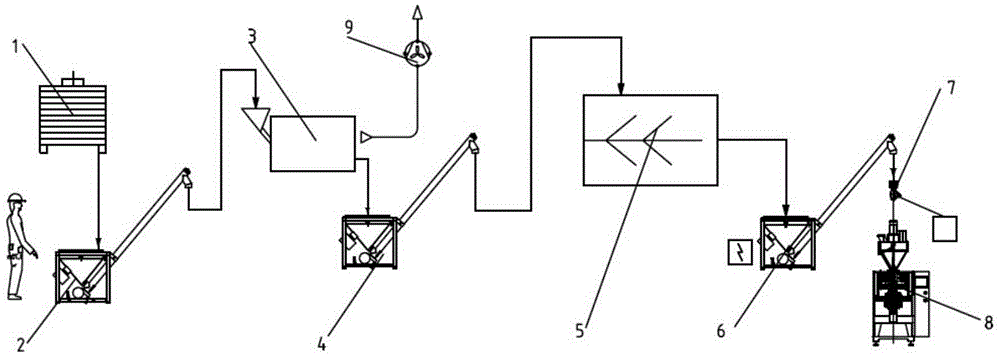

[0027] The invention provides a production line for processing cooked flour of wheat aleurone layer content, the production line comprises a material selection unit, a ripening equipment assembly (2), a cooling unit (5), a detection unit and a packaging unit (7, 8).

[0028] The material selection unit has a 100-150-mesh multi-layer sieve screening device, through which the rough-selected wheat aleurone layer content raw flour is screened, and the particles with an average particle size of less than 75 μm are screened out. Wheat aleurone layer content powder, while using an electronic moisture meter to sample and quickly measure the humidity of the screened wheat aleurone layer content powder (hereinafter uniformly use "material" instead of "wheat aleurone layer content powder") to ensure The moisture content of the material to be processed under this process is less than 10%. Specifically, the multi-layer screens of the material selection unit can be arranged in multiple laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com