Method for pre-treating landfill leachate by coagulation-ozonation

A technology of landfill leachate and ozone oxidation, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high power consumption, poor operation effect and high cost. , to achieve the effect of fast settling speed and large floc particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] After roughly filtering the landfill leachate, adjust the pH value to 7-8, and add polysilicate aluminum sulfate coagulant (silicon, aluminum, iron, etc.) The content ratio is 2:1:1) for 10-20 minutes, after 40-60 minutes of precipitation, the supernatant is passed through the ozone oxidation tank for ozone oxidation treatment with an ozone concentration of 6g / L for 10 minutes, and the effluent is pretreated wastewater, which is introduced into the subsequent in the anaerobic-aerobic biological treatment process.

Embodiment 2

[0016] Embodiment two: processing effect

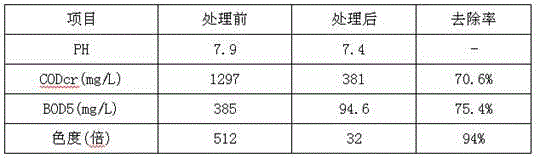

[0017] Using the pretreatment method described in the present invention, a certain landfill leachate is pretreated, and the pretreatment effect is as shown in Table-1:

[0018] Table-1 Treatment effect

[0019]

[0020] As can be seen from Table-1, the pretreatment method of the present invention has a removal rate of more than 70.6% to COD of landfill leachate, a removal rate of BOD5 of more than 75.4%, and a chroma removal rate of more than 94%. After pretreatment The COD, BOD, and chroma of the wastewater are greatly removed, creating favorable conditions for subsequent treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com