High-brightness composite ABS (Acrylonitrile Butadiene Styrene) material and preparation method thereof

A technology of ABS material and high-speed mixer, which is applied in the field of ABS composite material and its preparation, can solve the problems of reduced impact resistance, unfavorable and impact of household appliance shell materials, and achieves the effects of good rigidity, excellent surface brightness, and thick material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

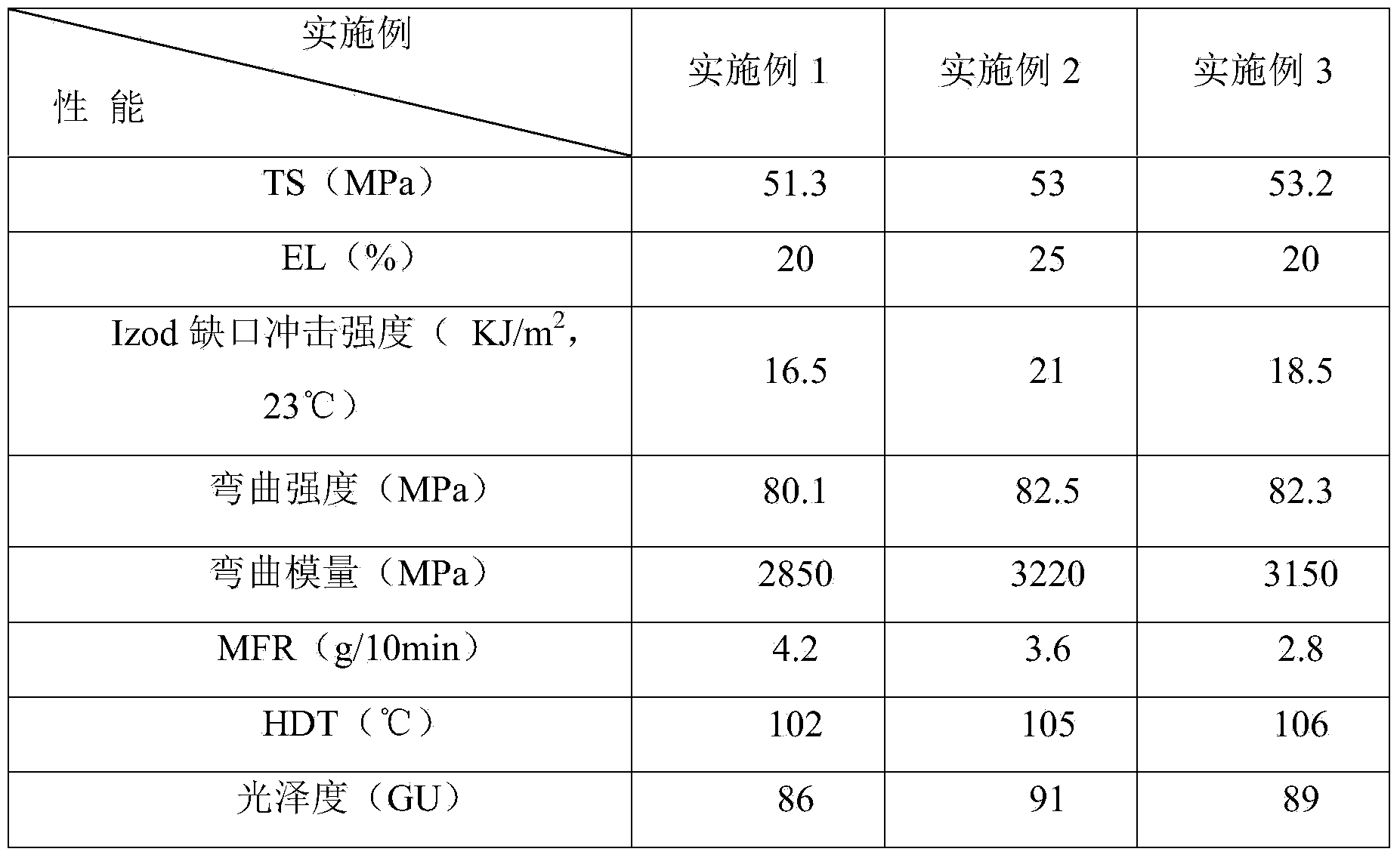

Examples

preparation example Construction

[0021] The specific preparation process is: (1) uniform mixing of raw materials: according to the ratio, pre-mix ABS, PMMA, PC and alloy compatibilizer SMA in a high-speed mixer, and mix uniformly; Mixing in the machine: Add the mixture obtained in step (1) into the twin-screw extruder for mixing. The temperature of the twin-screw extruder is set between 190 and 230°C, and the speed of the twin-screw extruder is 360-360°C. 400rpm; (3) Extrude the obtained material, cool it, and cut it into pellets to obtain a high-brightness composite ABS material.

[0022] PMMA is a high-transparency, high-gloss amorphous material that has good compatibility with ABS. PC is a high-strength, high-gloss, high-heat-resistant transparent material that can form an alloy with ABS. The alloy has excellent mechanical properties and gloss.

[0023] PMMA is used in the composite material, which has high gloss, can improve the toughness of ABS, and can give the composite material moderate impact streng...

Embodiment 1

[0026] Mix 62 parts of ABS, 25 parts of PMMA, 8.2 parts of PC, 4 parts of SMA, and 0.8 parts of antioxidant in a high-speed mixer, then feed into a twin-screw extruder, and the blend is mixed in a twin-screw extruder For refining, the temperature of each section of the twin-screw extruder is set as T1=190°C, T2=200°C, T3=205°C, T4=215°C, T5=220°C, T6=220°C. The rotational speed of the twin-screw extruder is 400rpm, and finally extruded and granulated to finally obtain a high-gloss ABS compound for home appliance shells.

Embodiment 2

[0028] Mix 57 parts of ABS, 27.4 parts of PMMA, 10 parts of PC, 5 parts of SMA, and 0.6 parts of antioxidant in a high-speed mixer, then feed into a twin-screw extruder, and the blend is mixed in a twin-screw extruder For refining, the temperature of each section of the twin-screw extruder is set as T1=190°C, T2=200°C, T3=210°C, T4=220°C, T5=230°C, T6=220°C. The rotational speed of the twin-screw extruder is 390rpm, and finally extruded and granulated to finally obtain a high-gloss ABS compound for home appliance shells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com