Addition Silicone Potting Compounds

A technology of silicone potting adhesive and composition, which is applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of increasing the stirring process, increasing the application cost, and detrimental to the stability of the application performance of the potting adhesive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

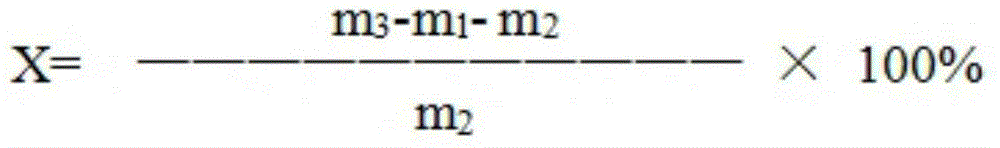

Image

Examples

Embodiment 1

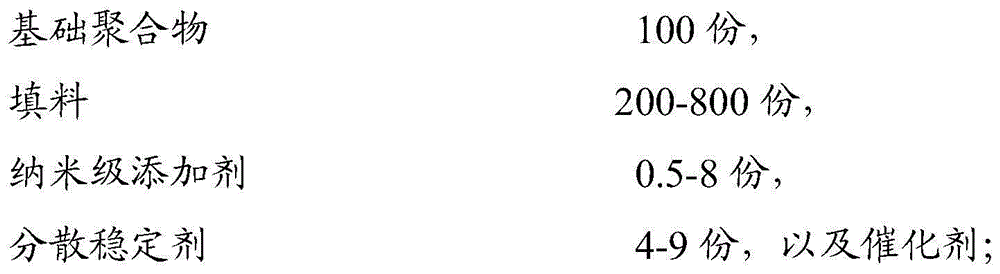

[0046] The preparation method of the two-component addition type silicone heat-conducting potting compound comprises the following steps:

[0047] After mixing 200 parts of thermally conductive fillers and 0.5 parts of nano-scale additives evenly, mix and stir with 4 parts of dispersion stabilizer and 60 parts of base polymer, heat up to 150°C for 3 hours under stirring and -0.08MPa vacuum conditions, and cool down to room temperature. To obtain matrix mixture A, mix matrix mixture A with 2 parts of catalyst, 0.2 parts of inhibitor, 8 parts of plasticizer and 40 parts of base polymer to obtain A component;

[0048] After mixing 200 parts of thermally conductive fillers and 0.5 parts of nano-scale additives evenly, mix and stir with 4 parts of dispersion stabilizer and 60 parts of base polymer, heat up to 150°C for 3 hours under stirring and -0.08MPa vacuum conditions, and cool down to room temperature. To obtain matrix mixture B, mix matrix mixture B with 20 parts of curing ag...

Embodiment 2

[0051] The preparation method of the two-component addition type silicone heat-conducting potting compound comprises the following steps:

[0052] After mixing 400 parts of thermally conductive filler and 4 parts of nanoscale additives evenly, mix and stir with 6 parts of dispersion stabilizer and 80 parts of base polymer, heat up to 130°C for 2 hours under stirring and -0.08MPa vacuum conditions, and cool down to room temperature. To obtain matrix mixture A, mix matrix mixture A with 2 parts of catalyst, 0.2 parts of inhibitor, 8 parts of plasticizer and 20 parts of base polymer to obtain A component;

[0053] After mixing 400 parts of thermally conductive filler and 4 parts of nanoscale additives evenly, mix and stir with 6 parts of dispersion stabilizer and 80 parts of base polymer, heat up to 130°C for 2 hours under stirring and -0.08MPa vacuum conditions, and cool down to room temperature. To obtain matrix mixture B, mix matrix mixture B with 25 parts of curing agent, 8 p...

Embodiment 3

[0056] The preparation method of the two-component addition type silicone heat-conducting potting compound comprises the following steps:

[0057] Mix 800 parts of thermally conductive filler and 8 parts of nano-scale additives evenly, then mix and stir with 9 parts of dispersion stabilizer and 40 parts of base polymer, heat up to 150°C for 2 hours under stirring and -0.08MPa vacuum conditions, and cool down to room temperature to obtain Matrix mixture A, mix matrix mixture A with 2 parts of catalyst, 0.2 parts of inhibitor, 8 parts of plasticizer and 60 parts of base polymer to obtain component A;

[0058] Mix 800 parts of thermally conductive filler and 8 parts of nano-scale additives evenly, then mix and stir with 9 parts of dispersion stabilizer and 40 parts of base polymer, heat up to 150°C for 2 hours under stirring and -0.08MPa vacuum conditions, and cool down to room temperature to obtain Matrix mixture B, mix matrix mixture B with 6 parts of curing agent, 8 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com