Negative-nonionic sulfonate high-temperature foamer for oil extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

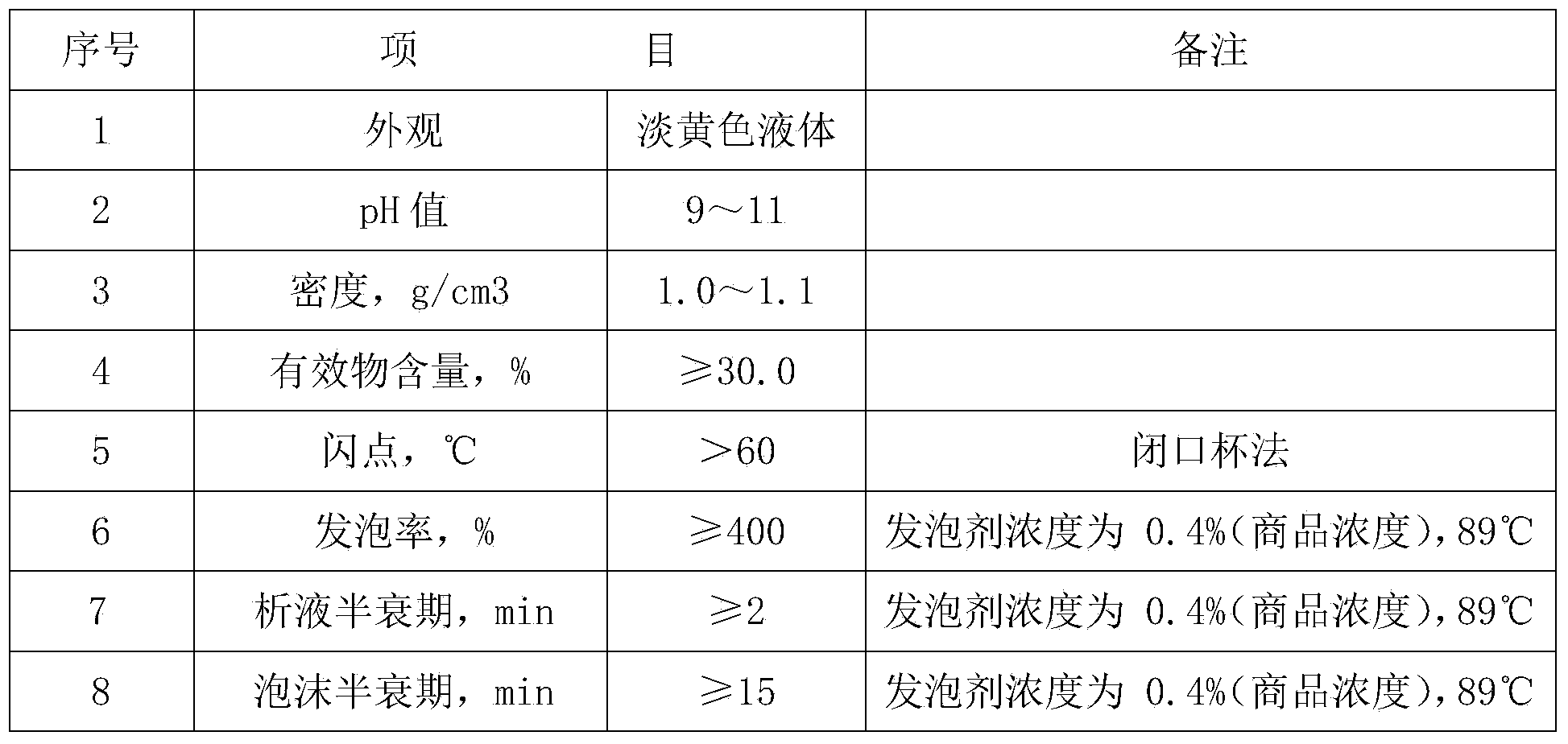

Image

Examples

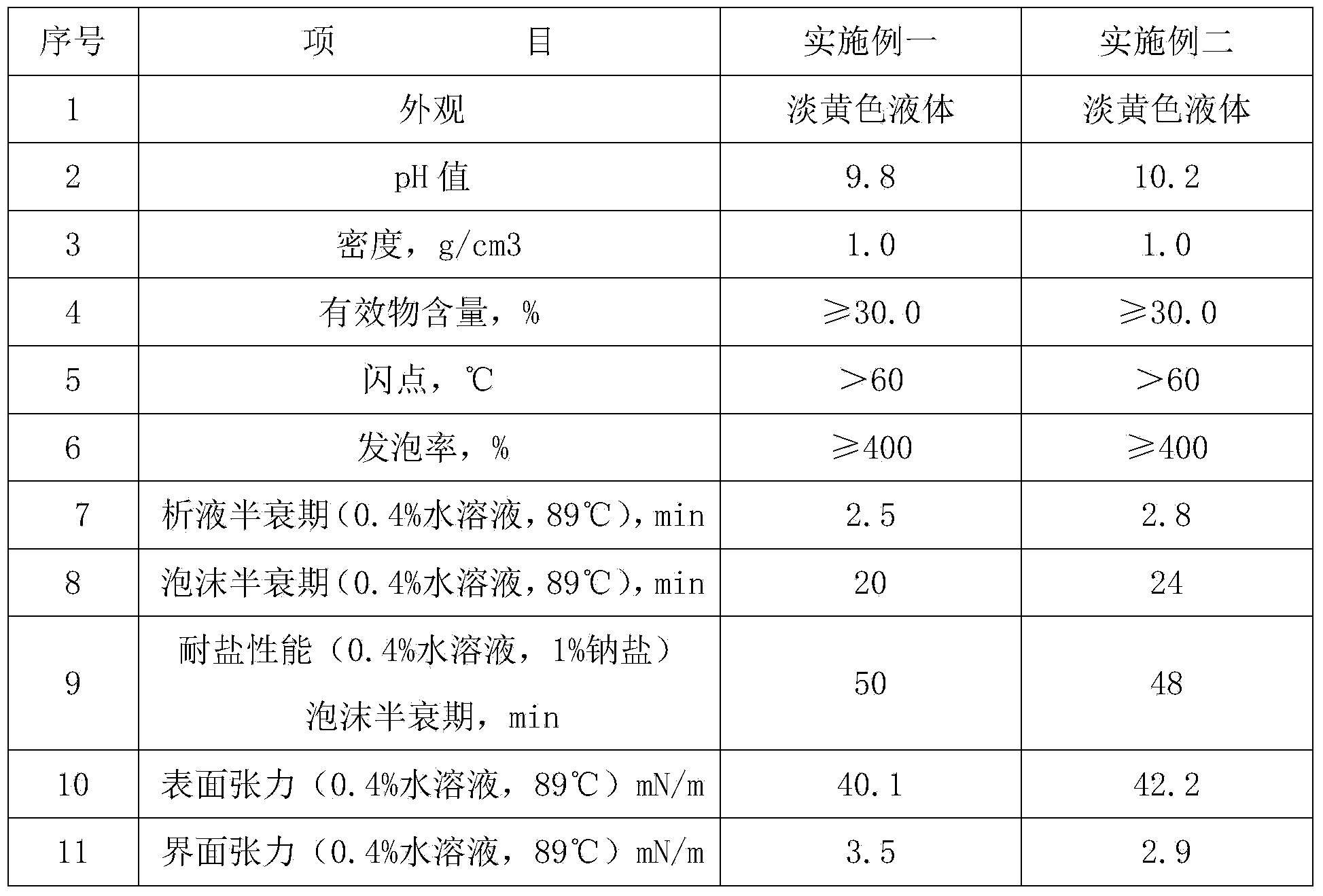

Embodiment 1

[0018] The quality of each raw material required to produce every ton of blowing agent of the present invention is: Spans class sulfonate surfactant (Spans-20) 400kg, Tween class sulfonate surfactant (Tweens-20) 350kg, Foam stabilizer (sodium carboxymethyl cellulose) 50kg, pH regulator 50kg, water 150kg.

Embodiment 2

[0020] The quality of each raw material required to produce every ton of blowing agent of the present invention is: Spans class sulfonate surfactant (Spans-20) 500kg, Tween class sulfonate surfactant (Tweens-20) 350kg, Foam stabilizer (sodium carboxymethylcellulose) 100kg, pH regulator 50kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com