Microalgae cultivation module and large-scale microalgae factory cultivation system

A microalgae cultivation and cultivation system technology, applied in biochemical instruments, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of low land utilization, large area and high management costs, and achieve controllable cultivation. Condition, operation and cleaning are convenient, the effect of large culture volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

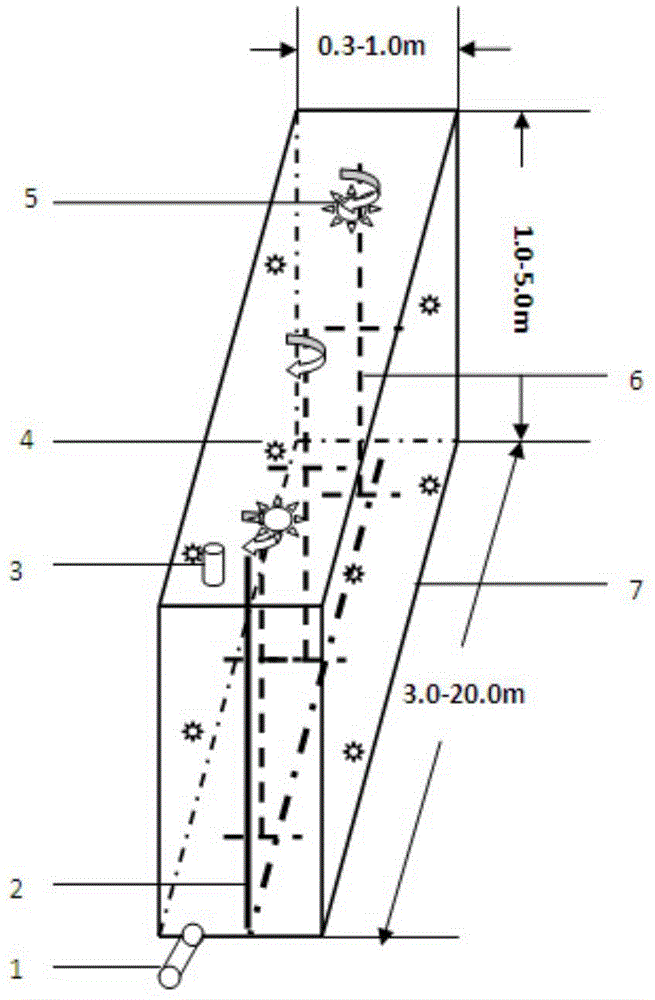

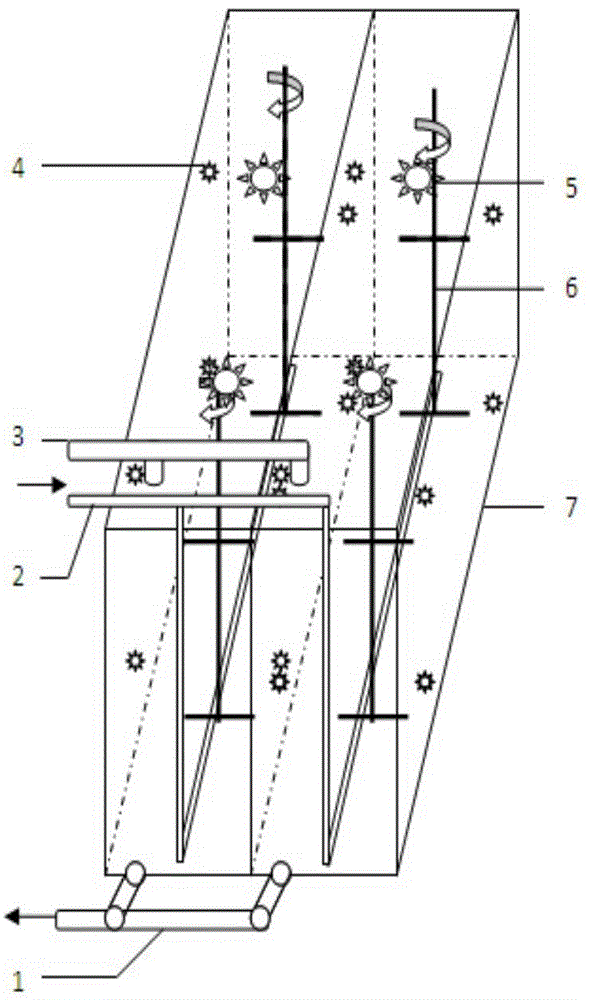

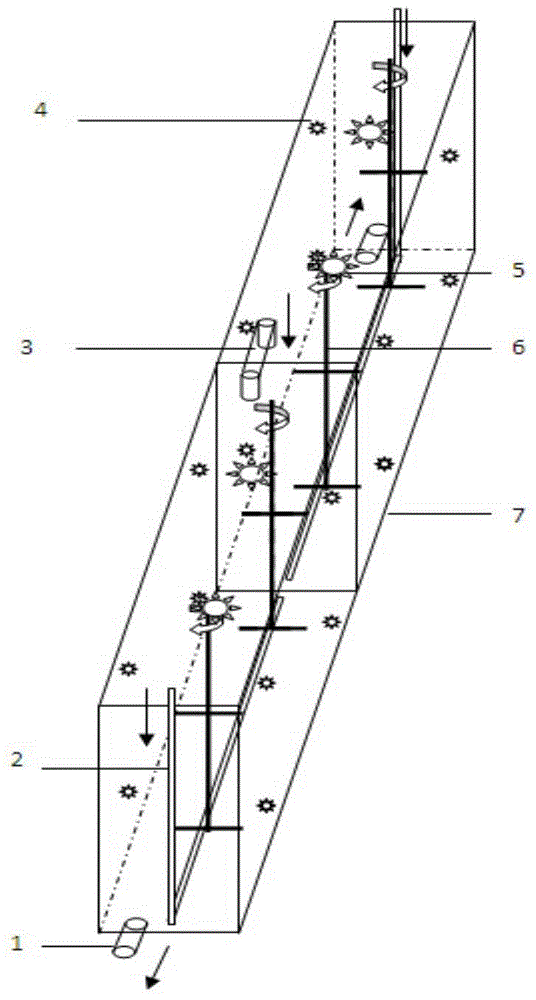

[0035] Embodiment: a kind of microalgae cultivation module provided by the invention, it mainly comprises:

[0036] A microalgae cultivation module, the length is 3-20m, the width is 0.3-1m, and the height is 1-5m.

[0037] A liquid replenishment mechanism, which is composed of a culture liquid preparation pool or preparation tank, a heater, a liquid replenishment pipeline, a nutrition analysis device and a water pump, and the liquid replenishment pipeline is connected with the culture solution inlet.

[0038] A carbon dioxide supply mechanism is composed of a carbon dioxide gas source, a vent pipe and a flow controller. The vent pipe is installed at the bottom of the culture module and has a vent hole on it. The carbon dioxide enters the culture solution through the gas source, the flow controller, the vent pipe and the vent hole.

[0039] A light control mechanism is composed of LED lights of different wavelengths, a light intensity control switch and a light type control sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com