High-flux screening method of nosiheptide active streptomycete high-yield strain

A technology of active Streptomyces and high-yielding strains, which is applied to the field of high-throughput screening of high-yielding strains of Streptomyces spp. active with nosiheptide, can solve the problems of high cost, time-consuming, laborious and other problems, and achieves an accurate and rapid screening method and improves screening efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

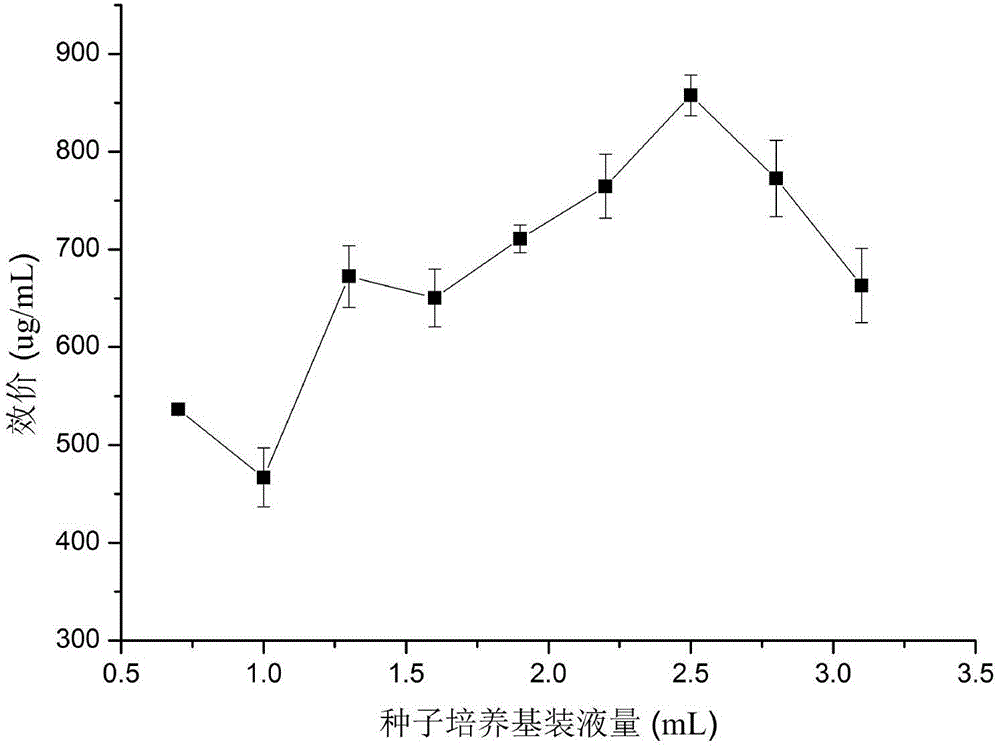

[0028] Example 1 24 deep-well plate seed medium loading volume on the impact of Nosiheptide titer

[0029] The initial volume of seed medium was selected as 0.7mL, 1.0mL, 1.3mL, 1.6mL, 1.9mL, 2.2mL, 2.5mL, 2.8mL, 3.1mL respectively, and their effects on the production of nosiheptide in 24 deep-well plates were compared. affect, as a result figure 1 shown. Depend on figure 1 It can be seen that the output of nosiheptide is the highest when the initial liquid loading volume is 2.5mL.

Embodiment 2

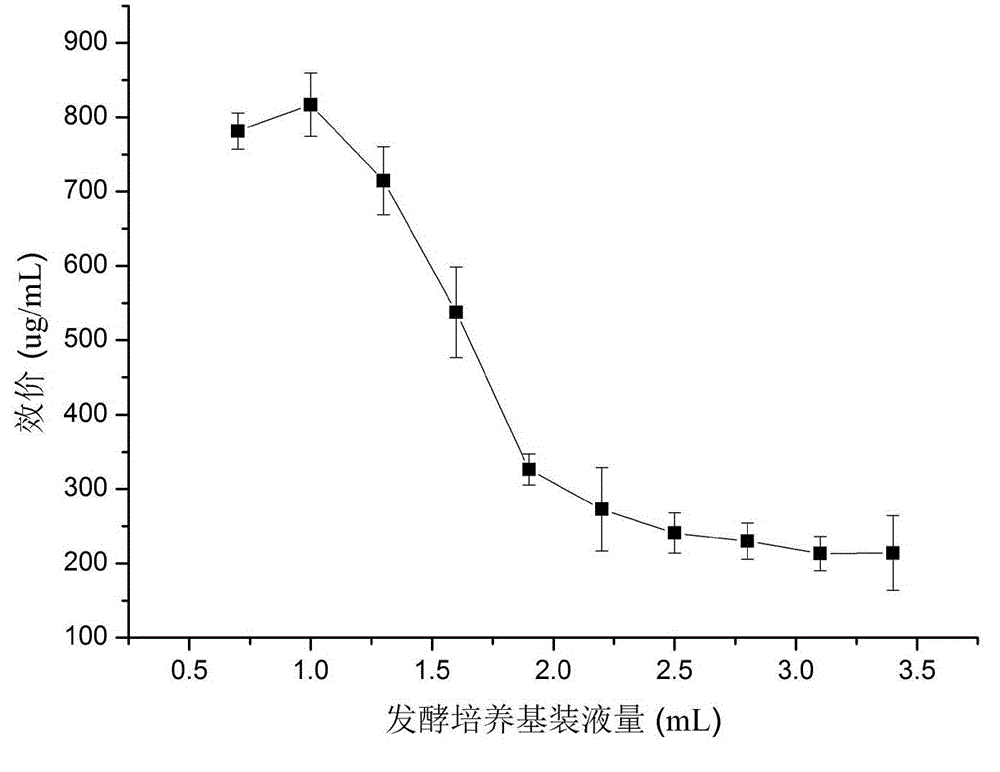

[0030] Embodiment 2 24 deep-well plate fermentation medium loading liquid volume on the influence of nosiheptide titer

[0031] According to mass percentage (%), starch 7.0, amylase (0.1% of starch), glucose 0.5, yeast powder 0.2, soybean powder (oil-containing) 4.0, (NH 4 ) 2 SO 4 0.1, KNO 3 0.05, NaCl 0.4, light calcium carbonate 0.4, and sterilized at 115°C for 25 minutes to obtain the fermentation medium.

[0032] Fermentation tests were carried out at 0.7mL, 1.0mL, 1.3mL, 1.6mL, 1.9mL, 2.2mL, 2.5mL, 2.8mL, 3.1mL, 3.4mL of fermentation medium, and the production of Nosiheptide was compared effect, the result is figure 2 shown. When the fermentation medium in the 24-deep-well plate was 1.0 mL, the yield of the 24-deep-well plate was the highest.

Embodiment 3

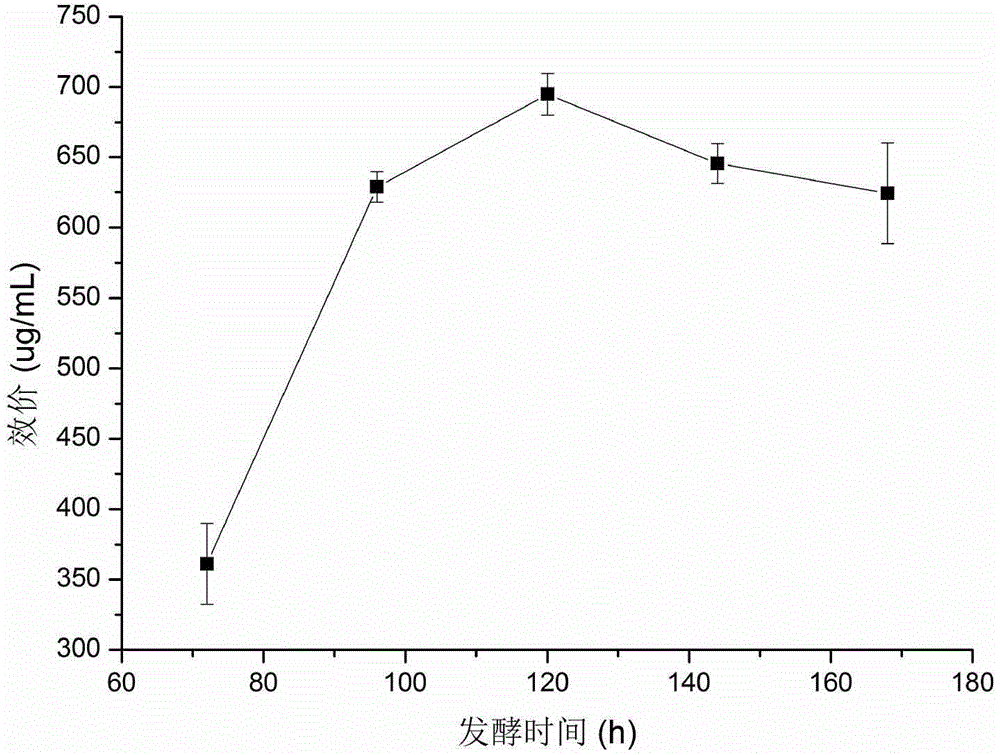

[0033] Example 3 Effect of fermentation time on 24 deep-well plate culture titer

[0034] Select different fermentation times to measure the output of Nosiheptide, the results are as follows: image 3 shown. Depend on image 3 It can be seen that in the early stage of fermentation, the yield of nosiheptide increases with the prolongation of fermentation time, but its yield decreases after 120 hours of fermentation. Therefore, it is advisable to choose 120 hours of fermentation time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com