Preparation method of corrosion-resistant and wear-resistant molybdenum-based amorphous coating for boiler tube bundle

A technology of amorphous coating and boiler tube bundle, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve problems such as the application of structural materials that cannot be large, and achieve good bonding, excellent corrosion resistance, and structural dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for preparing the corrosion-resistant and wear-resistant molybdenum-based amorphous coating for boiler tube bundles in this embodiment comprises the following steps:

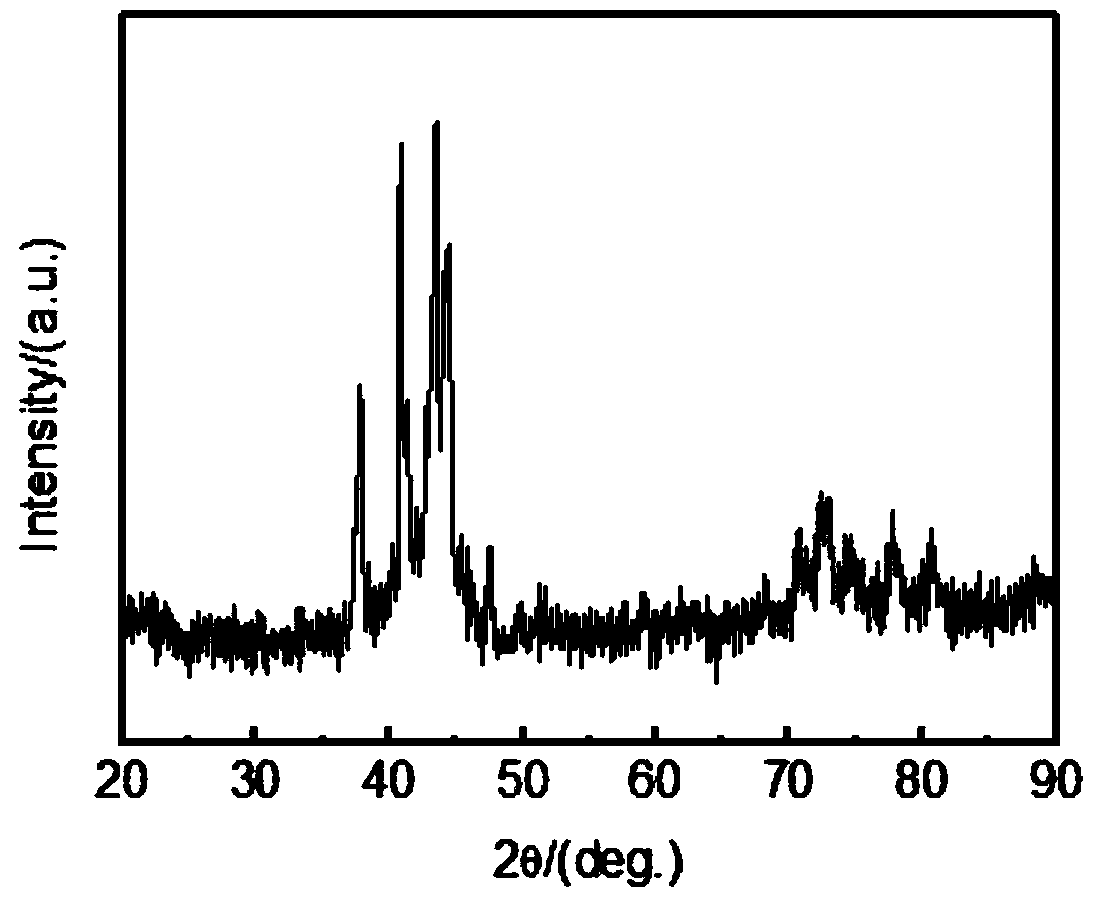

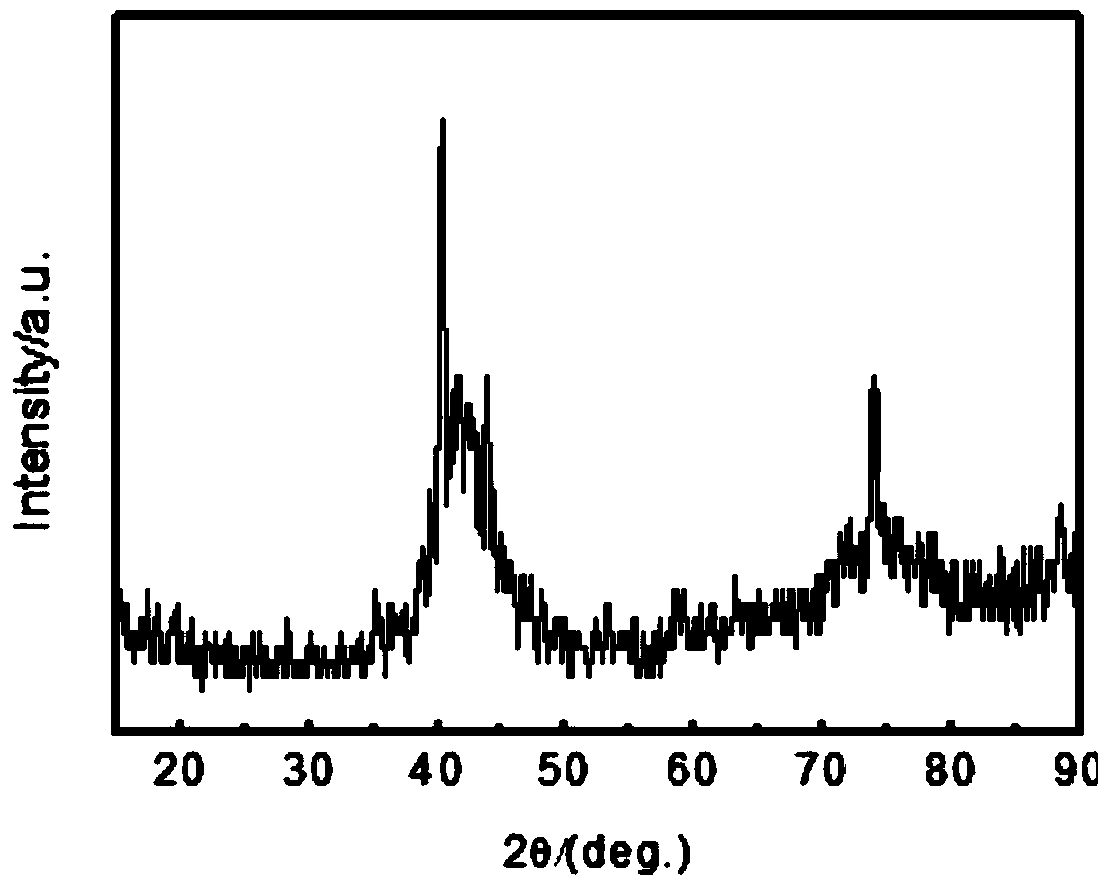

[0028] Step 1. Prepare molybdenum-based amorphous alloy powder by aerosol method. The molybdenum-based amorphous alloy powder is made by mixing the following raw materials in weight percentage: Fe7.5%, Cr15.0%, Ni5.0%, Si6. 5%, Al1.5%, C4.6%, W1.5%, Y0.2%, the balance is Mo and unavoidable impurities; the particle size of the molybdenum-based amorphous alloy powder is 50 μm;

[0029] Step 2. Prepare a corrosion-resistant and wear-resistant molybdenum-based amorphous coating on the surface of the boiler tube bundle by using a plasma spraying process. The process parameters of the plasma spraying process are: arc voltage 63V, arc current 475A, argon flow rate is 20L / min, the hydrogen flow rate is 7L / min, the spray gun moving speed is 65mm / s, and the spraying distance is 100mm; the thickness of th...

Embodiment 2

[0038] The method for preparing the corrosion-resistant and wear-resistant molybdenum-based amorphous coating for boiler tube bundles in this embodiment comprises the following steps:

[0039] Step 1. Prepare molybdenum-based amorphous alloy powder by aerosol method. The molybdenum-based amorphous alloy powder is made by mixing the following raw materials in weight percentage: Fe10.5%, Cr18.6%, Ni8.5%, Si7. 44%, Al0.8%, C6.98%, W4.5%, Y1.2%, the balance is Mo and unavoidable impurities; the particle size of the molybdenum-based amorphous alloy powder is 60 μm;

[0040] Step 2: Prepare a corrosion-resistant and wear-resistant molybdenum-based amorphous coating on the surface of the boiler tube bundle by using a plasma spraying process. The process parameters of the plasma spraying process are: arc voltage 62V, arc current 450A, argon gas flow rate is 20L / min, the hydrogen flow rate is 6L / min, the spray gun moving speed is 65mm / s, and the spraying distance is 100mm; the thicknes...

Embodiment 3

[0043] The method for preparing the corrosion-resistant and wear-resistant molybdenum-based amorphous coating for boiler tube bundles in this embodiment comprises the following steps:

[0044] Step 1. Prepare molybdenum-based amorphous alloy powder by aerosol method. The molybdenum-based amorphous alloy powder is made by mixing the following raw materials in weight percentage: Fe9.0%, Cr16.8%, Ni6.75%, Si6. 97%, Al1.15%, C5.79%, W3.0%, Y0.7%, the balance is Mo and unavoidable impurities; the particle size of the molybdenum-based amorphous alloy powder is 40 μm;

[0045] Step 2, using a plasma spraying process to prepare a corrosion-resistant and wear-resistant molybdenum-based amorphous coating on the surface of the boiler tube bundle. The process parameters of the plasma spraying process are: arc voltage 70V, arc current 550A, argon flow is 25L / min, the hydrogen flow rate is 8L / min, the spray gun moving speed is 80mm / s, and the spraying distance is 110mm; the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com