Novel electronic detonator exploder host

A technology of electronic detonators and detonators, applied in blasting tubes, weapon accessories, offensive equipment, etc., can solve problems such as large contact resistance, serious contact sparks, threats to the life safety of operators, etc., and achieve low power consumption and low working voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

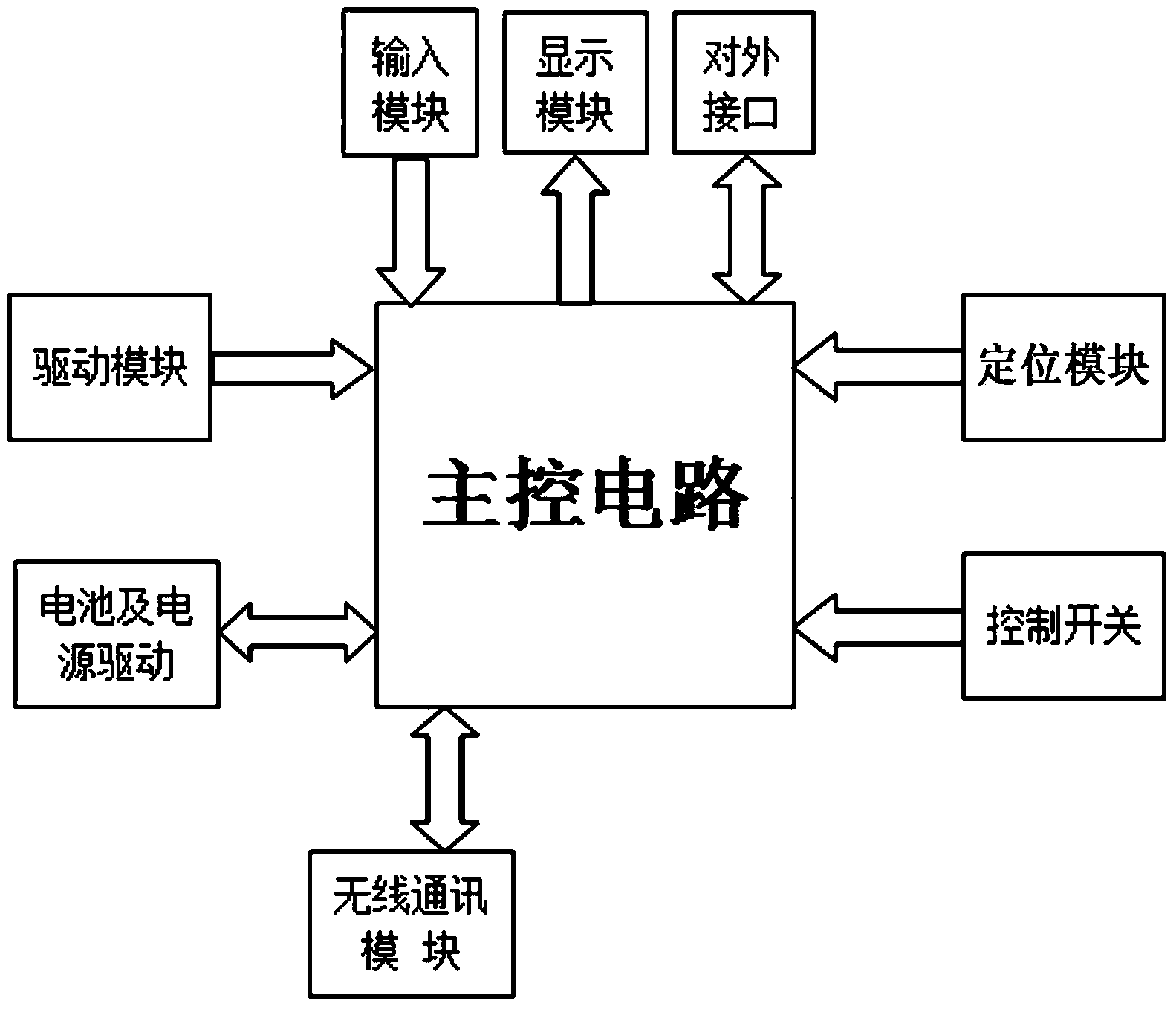

[0014] Such as figure 1 As shown, a new type of electronic detonator detonator host, including an explosion-proof shell, the explosion-proof shell is provided with a main control circuit, a drive module, a positioning module, a control switch and an input module, and the main control circuit is provided with a battery and a power drive. , a wireless communication module and an external interface, and connected to a display module arranged on the explosion-proof casing, and the drive module, input module, positioning module and control switch are connected to the main control circuit.

[0015] The explosion-proof shell is made by mixing phenolic resin and glass fiber filaments. The material has good mechanical strength, high heat resistance temperature, stable dimensions, and has good insulation, moisture resistance and flame retardancy. In terms of structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com