Gas sensitive material and preparation method and application thereof

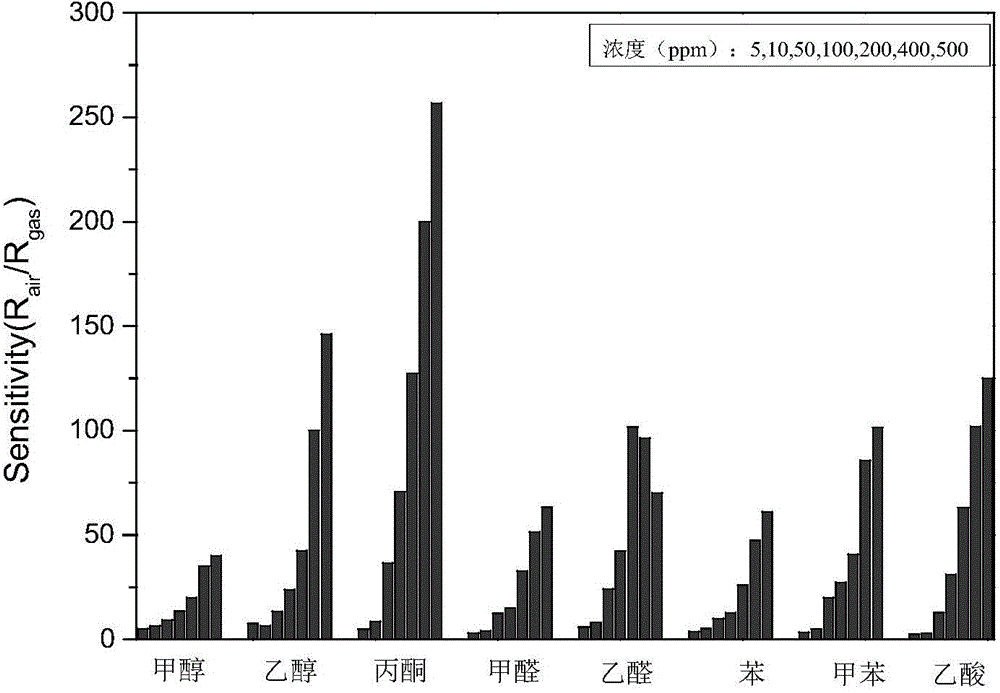

A gas-sensitive material and sediment technology, which is applied in the direction of analyzing materials, material resistance, and material analysis through electromagnetic means, can solve the problems of high concentration detection limit and low sensitivity, and achieve simple and easy control of the preparation process, excellent sensitivity and The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

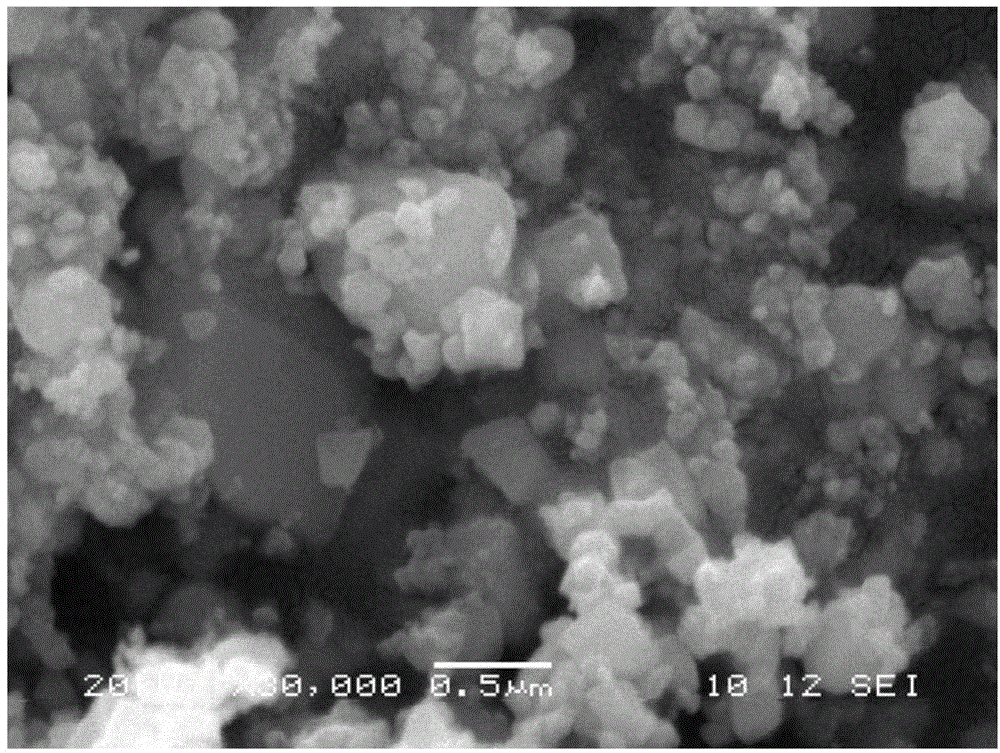

[0032] (1) to 0.5mol / L SnCl 4 ·5H 2 Add ammonia water with a mass percentage concentration of 20% in the O aqueous solution, stir vigorously at 50°C until the solution pH=10, and obtain a precipitate and a mother liquor, age the precipitate in the mother liquor at 50°C for 5 hours, centrifuge after aging, and wash with distilled water until The filtrate is neutral, the precipitate is dried at 80°C for 12h, and the dried product is calcined at 800°C in air for 5h to obtain submicron SnO 2 .

[0033] (2) 0.2mol / L SnCl 4 ·5H 2 40ml of aqueous O solution was placed in a hydrothermal reaction kettle, and the precipitate and mother liquor were obtained after reacting at 160°C for 12 hours. After the reaction kettle was naturally cooled, the precipitate was centrifuged and washed with distilled water until the filtrate was washed with AgNO 3 Cl cannot be detected - , the precipitate was dried at 80 °C for 12 h to obtain nanoscale SnO 2 .

[0034] (3) Submicron and nanoscale Sn...

Embodiment 2

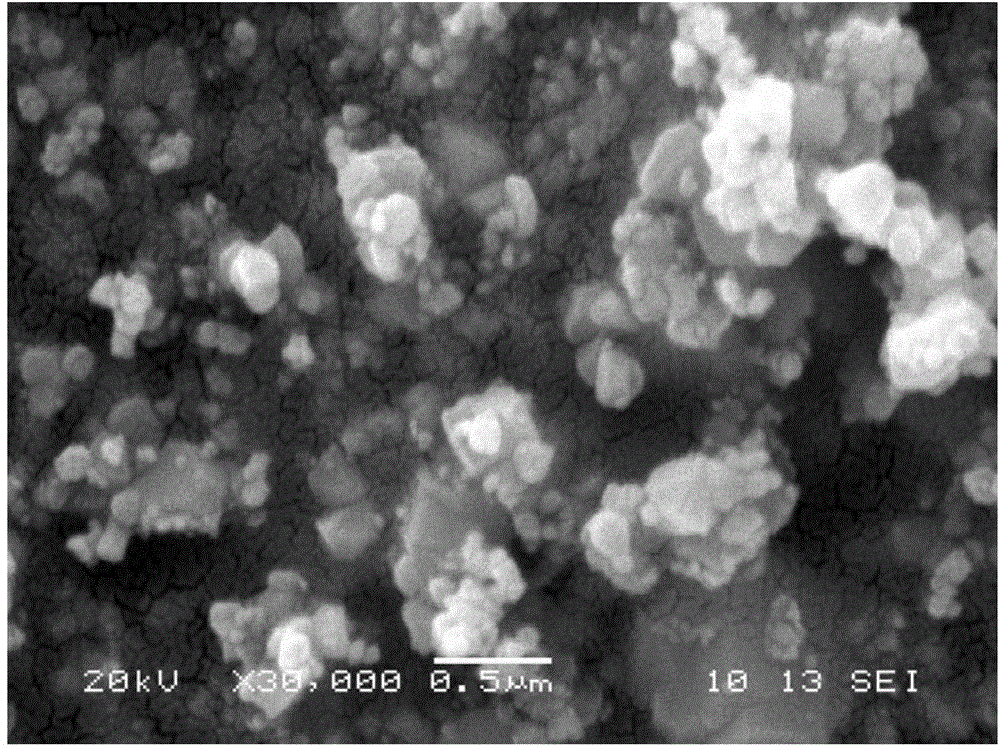

[0039] (1) To 1mol / L SnCl 4 ·5H 2 Add ammonia water with a mass percentage concentration of 20% in the O aqueous solution, stir vigorously at 50°C until the solution pH=10, and obtain a precipitate and a mother liquor, age the precipitate in the mother liquor at 50°C for 5 hours, centrifuge after aging, and wash with distilled water until The filtrate is neutral, the precipitate is dried at 80°C for 12h, and the dried product is calcined at 800°C in air for 5h to obtain submicron SnO 2 .

[0040] (2) 0.4mol / L SnCl 4 ·5H 2 40ml of aqueous O solution was placed in a hydrothermal reaction kettle, and the precipitate and mother liquor were obtained after reacting at 160°C for 12 hours. After the reaction kettle was naturally cooled, the precipitate was centrifuged and washed with distilled water until the filtrate was washed with AgNO 3 Cl cannot be detected - , the precipitate was dried at 80 °C for 12 h to obtain nanoscale SnO 2 .

[0041] (3) Submicron and nanoscale SnO ...

Embodiment 3

[0044] (1) To 1mol / L SnCl 4 ·5H 2 Add ammonia water with a mass percentage concentration of 20% in the O aqueous solution, stir vigorously at 50°C until the solution pH=10, and obtain a precipitate and a mother liquor, age the precipitate in the mother liquor at 80°C for 5 hours, centrifuge after aging, and wash with distilled water until The filtrate is neutral, the precipitate is dried at 80°C for 12h, and the dried product is calcined at 1000°C in air for 5h to obtain submicron SnO 2 .

[0045] (2) 0.4mol / L SnCl 4 ·5H 2 40ml of aqueous O solution was placed in a hydrothermal reaction kettle, and the precipitate and mother liquor were obtained after reacting at 120°C for 12 hours. After the reaction kettle was naturally cooled, the precipitate was centrifuged and washed with distilled water to the filtrate, and the AgNO 3 No Cl- was detected, and the precipitate was dried at 80°C for 12h to obtain nanoscale SnO 2 .

[0046] (3) Submicron and nanoscale SnO 2 Ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com