Stripper for stripping photoresist

A stripping liquid and solvent technology, applied in the field of photoresist, can solve the problems of affecting the safety of operators, corroding metal wiring, poor stripping effect, etc., achieve good stripping effect, increase stripping speed, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

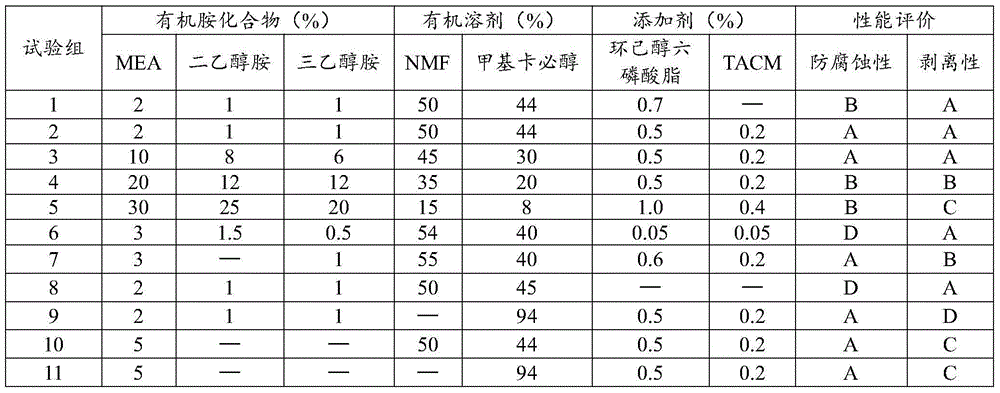

[0018] In this example, the substrates with photoresist are manufactured using the existing technology, and the prepared substrates with photoresist are respectively immersed in the stripping solution of the test group. For rinsing treatment, the components and dosage of each test group are shown in Table 2. The peeling results were carried out with reference to the conventional metal corrosion resistance and peelability evaluation standards. The metal corrosion resistance and peelability evaluation standards are shown in Table 1, and the peeling results are shown in Table 2. In this example, the balance in each test group is deionized water.

[0019] Table 1 Evaluation criteria of stripping liquid effect

[0020] peeling effect Corrosion resistance of metal wiring Stripping property of photoresist A No corrosion observed at all completely stripped B Almost no corrosion is observed almost completely stripped C corroded There is a little re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com