Precise micro-dynamic parallel locating system and method for micro-nano operation environment

An operating environment and positioning system technology, which is applied in the fields of precision measurement, precision positioning, and precision manufacturing, can solve problems such as assembly errors of parallel mechanism branch chains, decrease in stiffness and load-bearing capacity, and influence on mechanism positioning accuracy, etc., to achieve the elimination of rotary joints Clearance, fast response, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

[0075] In the accompanying drawings:

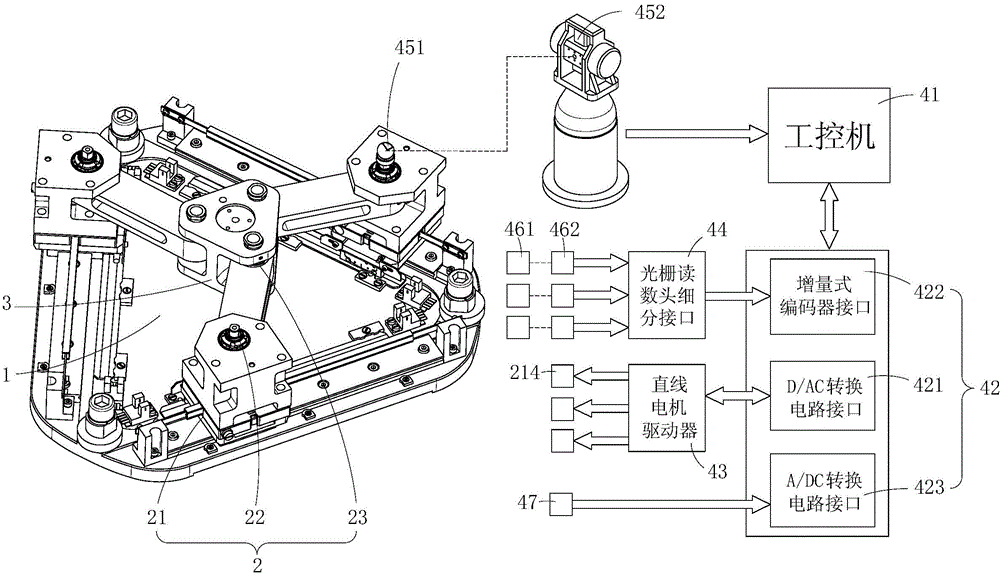

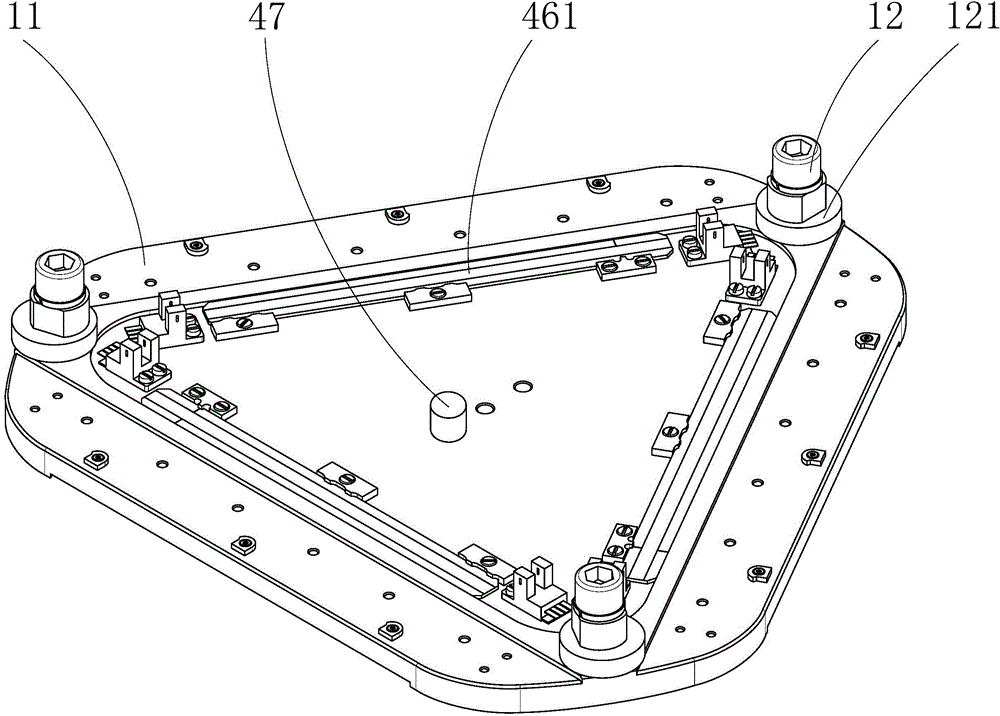

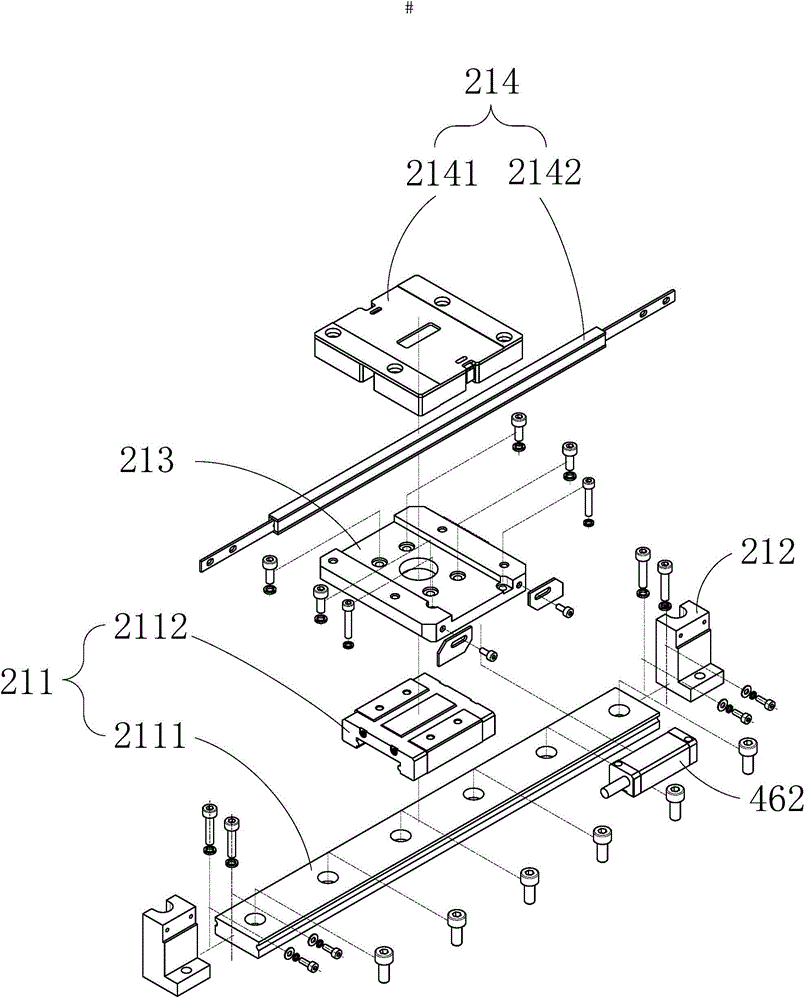

[0076] 1-Base; 11-Bottom plate; 12-Eccentric wheel clamping mechanism; 121-Eccentric wheel column; 2-Ultrasonic motor drive branch chain; 21-Active moving joint; 211-Rolling linear bearing; 2111-guide rail; 2112-slide Block; 212-motor fixing bracket; 213-connecting plate; 214-linear ultrasonic motor; 2141-base body; 2142-guide rod; 22-passive rotating joint I; 221-joint frame; 222-rotating shaft I, 223-precision Bearing Ⅰ; 224-precision bearing Ⅱ; 225-lock nut Ⅰ; 226-elastic deformation part; 227-press plate; 23-passive rotating joint Ⅱ; 231-connecting rod; 232-precision bearing Ⅲ; 233-precision bearing Ⅳ 234-Rotary shaft Ⅱ; 235-end cover; 236-lock nut Ⅱ; 3-moving platform; 41-industrial computer; 42-controller; 421-D / AC conversion circuit; 422-incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com