Non-discharge method for treating highly concentrated organic waste water using bio-evaporation

A technology of organic wastewater and biological evaporation, applied in the adjustment method of biological treatment, biological organic part treatment, biological water/sewage treatment, etc., can solve control problems, obtain clean water, and methanogens are susceptible to various toxic substances Damage and other issues, to achieve the effect of minimizing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] Example 1: Biovaporization using glucose solution

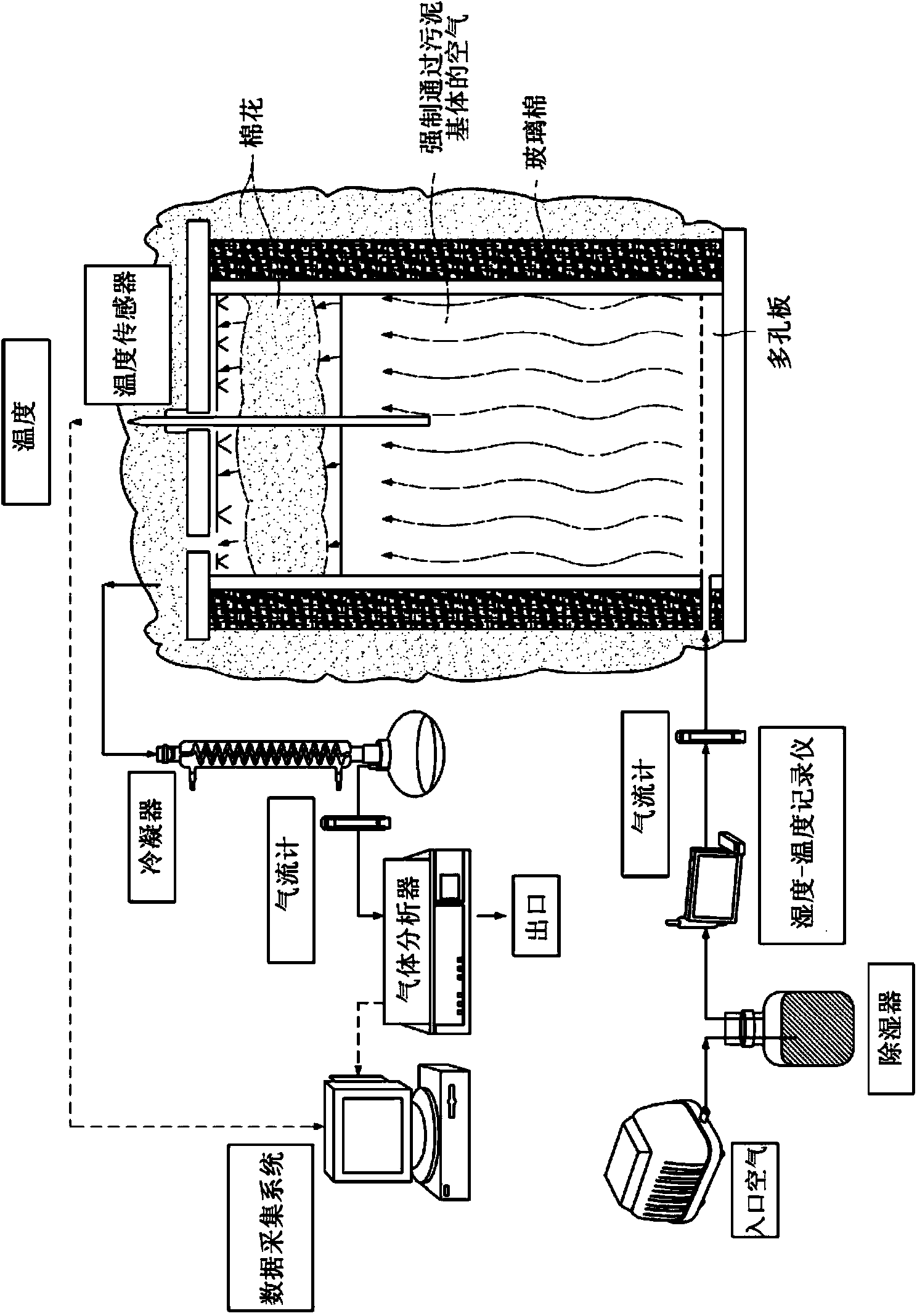

[0144] Bioevaporation was carried out by mixing 404 mL of glucose solution (610 g / L) with 7.29 kg of biologically dried sludge (water content: 56.5% by weight), adding the mixture to a 28.3 L adiabatic reactor, and then adding 2.04 L Air was supplied to the reactor at a rate of 100 Å / min.

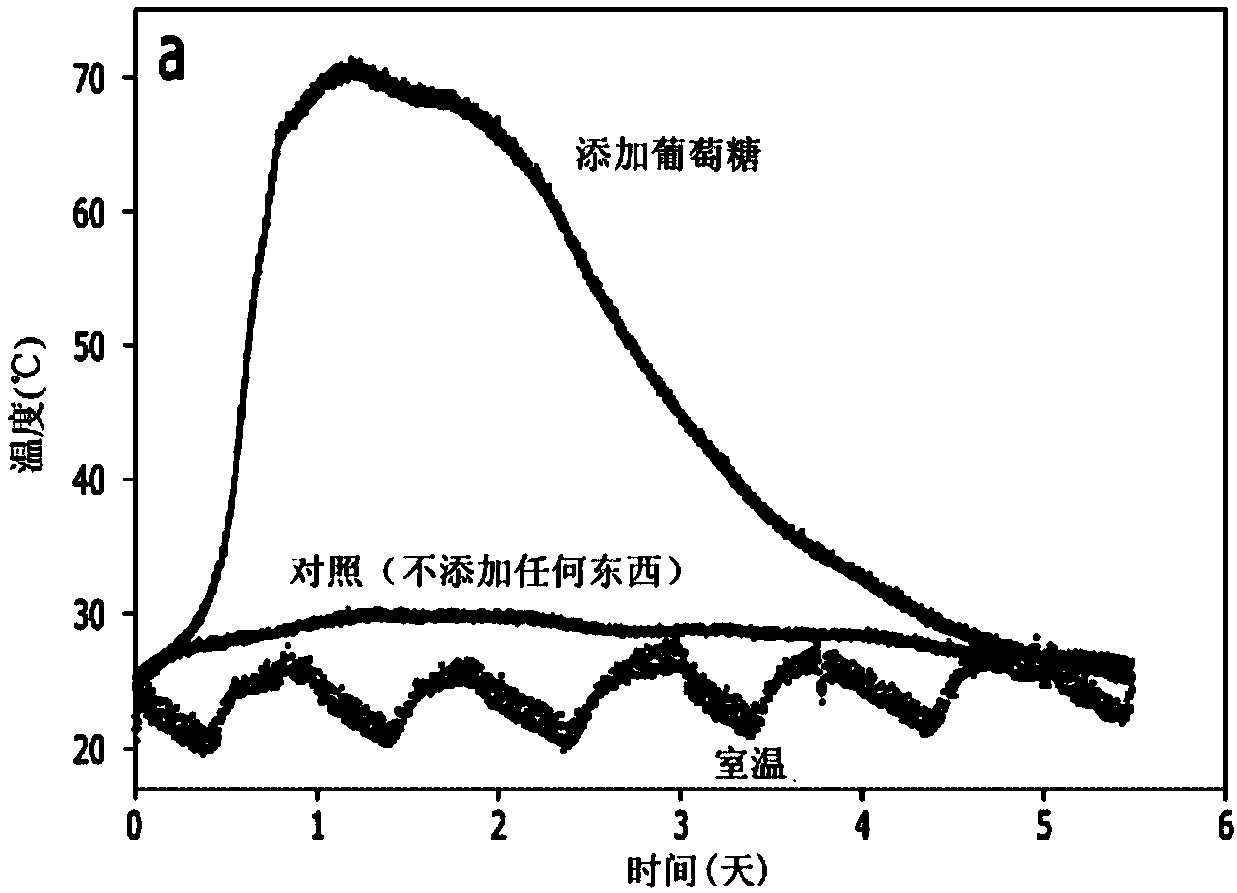

[0145] Such as image 3 As shown in , the temperature of the reactor increases rapidly after adding the glucose solution to the reactor. The temperature reached 71.4°C after 28 hours and returned to room temperature after 96 hours. However, the temperature of the control reactor to which no glucose solution was added was maintained at about room temperature. After observing the temperature changes, it was confirmed that the microorganisms in the sludge bed utilized glucose as an energy source for their metabolism with a short lag time.

[0146] Such as Figure 4 As shown in , when the reactor temperature increases, the oxygen...

Embodiment 2 to 6

[0180] Examples 2 to 6 and comparative example: biovaporization using glucose solution

[0181] In order to determine the relationship between glucose concentration and water evaporation, bioevaporation experiments were carried out with different glucose solutions prepared in Examples 2 to 6 and Comparative Example.

[0182] The heat production and water evaporation of the glucose concentration according to the theoretical simulations of Examples 2 to 6 and Comparative Example 1 are shown in Table 5 below.

[0183] 【table 5】

[0184]

[0185] To calculate the values in Table 5 above, since the heat used for water evaporation was found to be 64.5% in Example 1, it was assumed that 65% of the heat generated by microbial metabolism had been used for water evaporation. Accordingly, assuming that the average temperature for biovaporization is 50 °C, the latent heat of water evaporation is 2344 kJ / kg. The amount of water evaporation by metabolic heat is calculated by dividi...

Embodiment 7 to 11

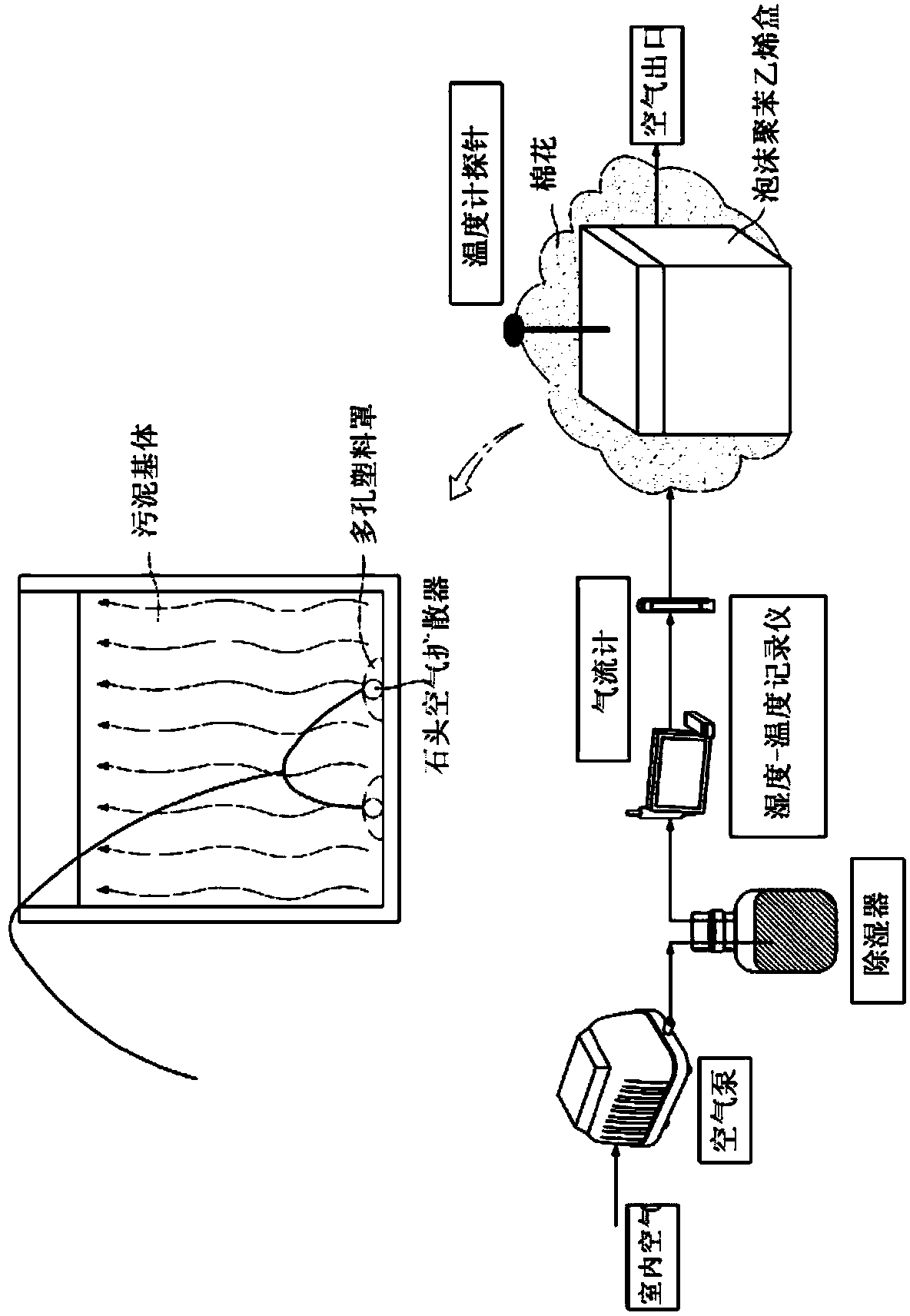

[0187] Examples 7 to 11 and Comparative Example: Biovaporization using a solution of food waste powder

[0188] Bioevaporation experiments were performed by mixing a solution of food waste instead of a glucose solution with biologically dried sludge to check whether the bioevaporation process can be practically applied to wastewater treatment. Food waste powders were prepared at concentrations of 42g / L, 82g / L, 120g / L, 157g / L and 194g / L and used in Examples 7 to 11, respectively. For the comparative example, 100 mL of water containing no food waste powder was used. The experimental results are shown in Figures 10 to 16 middle. In order to regulate the rapid microbial metabolism of food waste, the food waste powder is prepared as fine particles with a diameter of 1 mm or less. The VS content of the food waste powder in a dry state was 93.4% relative to the total solids.

[0189] Since the solution of food waste powder (194 g VS / L) contained readily biodegradable VS, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com