Wear-resistant heat-vulcanized rubber shoes

A technology of heat vulcanization and rubber shoes, which is applied to soles, insoles, footwear, etc., and can solve problems such as easy fatigue, insufficient aesthetics, and short storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

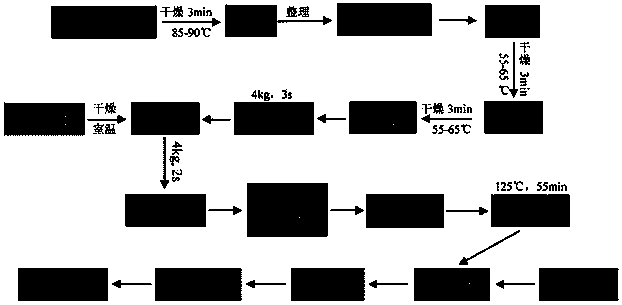

Method used

Image

Examples

Embodiment 1

[0185] Embodiment 1, prepare hot-vulcanized rubber shoes

[0186] 1) Wrap formula

[0187] The raw materials used in the preparation of wear-resistant heat-vulcanized rubber shoes are calculated in parts by mass (phr), including 60 phr of natural rubber, 40 phr of styrene-butadiene rubber, 50 phr of precipitated white carbon black, 20 phr of white oil, 25 phr of titanium dioxide, light carbonic acid Calcium 50phr, ultramarine 0.5phr, polyethylene glycol 3phr, diethylene glycol 2phr, stearic acid 2phr, zinc oxide 4phr, accelerator DM2phr, accelerator NS0.3phr, antioxidant SP-C 1.5phr, sulfur 1.5phr.

[0188] See Table 1 for the performance of the semi-finished product of the strip glue formula.

[0189] 2) Rubber outsole formula

[0190] The raw materials used to prepare the rubber outsole of wear-resistant heat vulcanized rubber shoes are calculated in parts by mass (phr), including natural rubber 75phr, butadiene rubber 25phr, zinc oxide 4phr, stearic acid 2phr, carbon blac...

Embodiment 2

[0200] Embodiment 2, preparation hot-vulcanized rubber shoes

[0201] 1) Wrap formula

[0202] The raw materials used in the preparation of wear-resistant heat vulcanized rubber shoes are calculated in parts by mass (phr), including 80 phr of natural rubber, 20 phr of styrene-butadiene rubber, 40 phr of precipitated white carbon black, 15 phr of white oil, 30 phr of titanium dioxide, light carbonic acid Calcium 40phr, Ultramarine 0.8phr, Polyethylene Glycol 2phr, Diethylene Glycol 1.5phr, Stearic Acid 1phr, Zinc Oxide 2phr, Accelerator DM 1phr, Accelerator NS 0.3phr, Antiaging Agent SP-C 2phr, Sulfur 2.5phr .

[0203] See Table 1 for the performance of the semi-finished product of the strip glue formula.

[0204] 2) Rubber outsole formula

[0205] The raw materials used to prepare the rubber outsole of wear-resistant heat vulcanized rubber shoes are calculated in parts by mass (phr), including 85phr of natural rubber, 15phr of butadiene rubber, 5phr of zinc oxide, 3phr of s...

Embodiment 3

[0209] Embodiment 3, preparation hot-vulcanized rubber shoes

[0210] 1) Wrap formula

[0211] The raw materials used in the preparation of wear-resistant heat vulcanized rubber shoes are calculated in parts by mass (phr), including natural rubber 70phr, styrene-butadiene rubber 30phr, precipitated white carbon black 45phr, white oil 20phr, titanium dioxide 25phr, light carbonic acid Calcium 45phr, Ultramarine 0.7phr, Polyethylene Glycol 2.5phr, Diethylene Glycol 2phr, Stearic Acid 1.5phr, Zinc Oxide 3phr, Accelerator DM 2phr, Accelerator NS 0.2phr, Antiaging Agent SP-C 1.5phr, Sulfur 2phr .

[0212] See Table 1 for the performance of the semi-finished product of the strip glue formula.

[0213] 2) Rubber outsole formula

[0214] The raw materials used to prepare the rubber outsole of wear-resistant heat vulcanized rubber shoes are calculated in parts by mass (phr), including 80phr of natural rubber, 20phr of butadiene rubber, 4.5phr of zinc oxide, 2.5phr of stearic acid, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com