Hydrogenation protection catalyst, and preparation method and application thereof

A hydrogenation protection and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

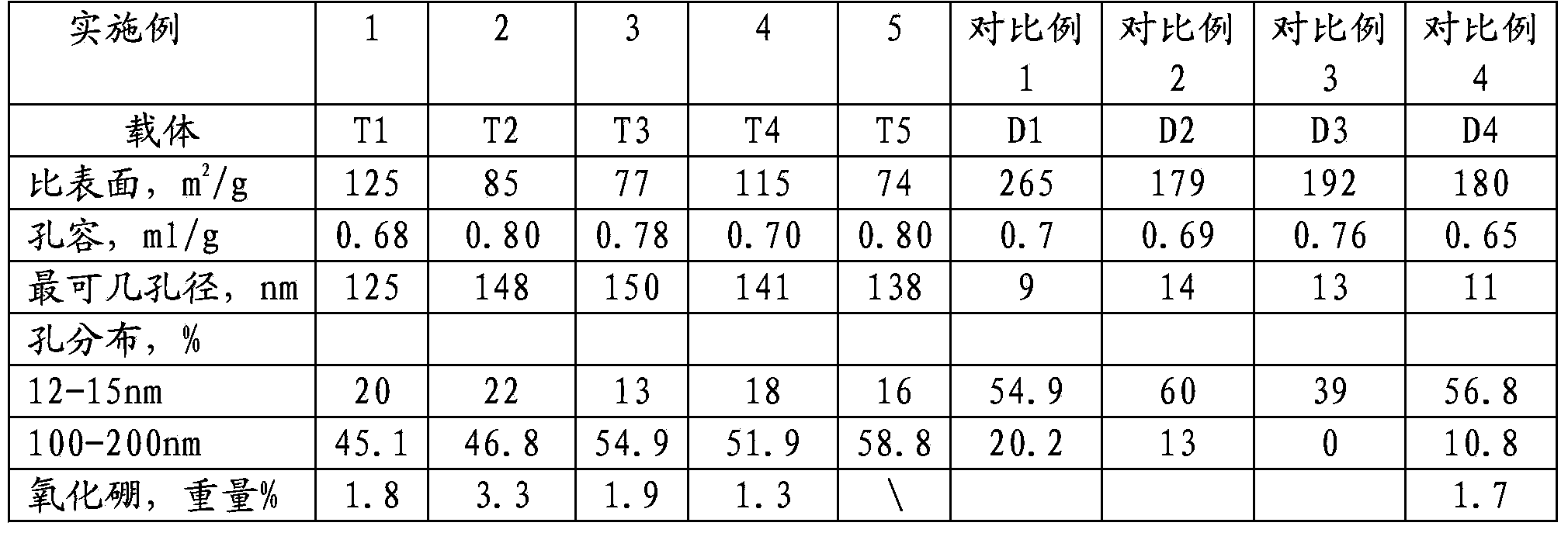

[0056] Weigh 200g of hydrated alumina (commercially purchased from Changling Oil Refinery Catalyst Plant, 65% by weight on a dry basis. The pore volume is 1.05 ml / g, and the specific surface area is 230 m 2 / gram, the diameter of the most possible pores is 20nm), 70 grams of α-alumina powder (formed by roasting the hydrated alumina used in this example at 1400 ° C for 6 hours), 9 grams of scallop powder and 15 grams of borax mixed , mix this mixture with 330 ml of ammonia solution with a concentration of 4% at room temperature, after mixing evenly, knead in a twin-screw extruder and extrude with a cylindrical orifice of φ2. After drying for 4 hours, it was calcined at 850°C for 2 hours to obtain carrier T-1 of the present invention. The specific surface, probable pore diameter, pore volume, and pore distribution of carrier T-1 were measured, and the results are shown in Table 1.

Embodiment 2

[0058] Weigh 180g dry rubber powder (commercially purchased from Changling Refinery Catalyst Plant, dry basis is 65% by weight. Pore volume is 1.05 ml / g, specific surface area is 285 m 2 120 grams of α-alumina powder (commercially purchased from Beijing Shunchuan Environmental Protection Technology Co., Ltd.), 9 grams of astragalus powder and 8 grams of boron oxide are mixed, and then add 10 grams of boric acid 330 milliliters of sodium aqueous solution, mixed evenly, kneaded in a twin-screw extruder and extruded with a cylindrical orifice plate of φ2.0mm, after that, the wet strip was dried at 120°C for 4 hours and then roasted at 850°C for 2 hours to obtain the present invention Carrier T-2. The specific surface, probable pore diameter, pore volume, and pore distribution of carrier T-2 were measured, and the results are shown in Table 1.

Embodiment 3

[0060] Weigh 150g of dry rubber powder (commercially purchased from Yantai Henghui Chemical Co., Ltd., the dry basis is 68% by weight. The pore volume is 1.08 ml / g, and the specific surface area is 188 m 2 / gram, the diameter of the most possible pores is 22nm), 150 grams of α-alumina powder (commercially purchased from Beijing Shunchuan Environmental Protection Technology Co., Ltd.), 9 grams of asparagus powder, 9 grams of methylcellulose and 20 grams of borax mixed, Then add 330 milliliters of aqueous solution containing 35 grams of ammonium bicarbonate, mix well and then shape according to the rolling ball molding method to obtain spherical particles with a particle size of 5.5-6.5 mm. The wet strip was dried at 120°C for 4 hours and then calcined at 800°C for 2 hours to obtain carrier T-3 of the present invention. The specific surface, probable pore diameter, pore volume, and pore distribution of carrier T-3 were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com