A kind of catalyst and filter screen thereof

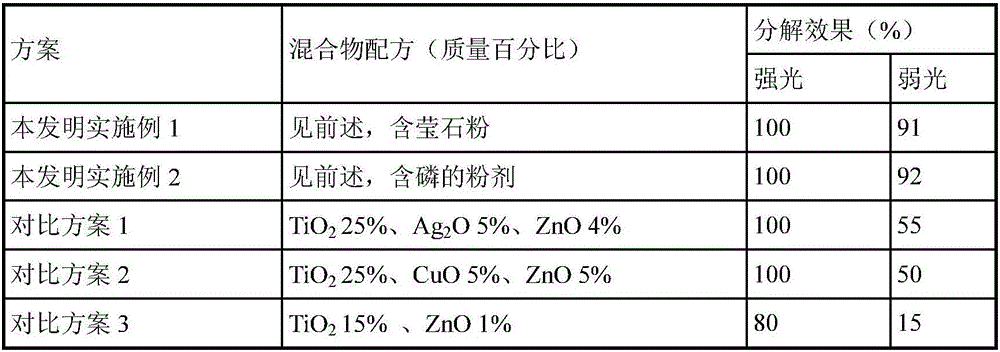

A catalyst and filter technology, which is applied in the direction of dispersion particle separation, irradiation, physical/chemical process catalyst, etc., can solve the problem of insufficient decomposition ability of titanium-containing coatings, and achieve strong oxidation decomposition ability, long service life and strong adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The raw materials used are calculated by weight: 60 parts of deionized water, 8 parts of titanium dioxide, 10 parts of silver nitrate, 2 parts of defoaming agent, 2 parts of wetting agent, 0.3 part of thickener, and 15 parts of fluorite powder. 0.3 parts of film-forming aids, 1 part of zinc oxide, and 4 parts of silicon dioxide. Wetting agent is a mixture of polyoxyethylene polyol ether and polyol ester, defoamer is a mixture of aliphatic hydrocarbon emulsion and non-silicone organic ester hydrocarbon, thickener is modified sodium polyacrylate, film-forming The auxiliary agent adopts the auxiliary agent of the model BYK-194 produced by the German BYK company. The above raw materials are placed in a container to mix and stir (stirring cowpea is 450 rpm) to make a hydrosol.

Embodiment 2

[0024] The raw materials used are calculated in parts by weight: 50 parts of deionized water, 18 parts of titanium dioxide, 6 parts of silver nitrate, 3 parts of defoamer, 6 parts of wetting agent, 0.3 part of thickener, and 15 parts of phosphorus-containing powder. 0.3 parts of film aid, 3 parts of zinc oxide, and 3 parts of silicon dioxide. The wetting agent is a mixture of polyoxyethylene polyol ether, polyol ester and polyoxyethylene alkaryl ether. The defoamer is a mixture of mineral oil-based silicon-containing mixture and non-silicone organic ester hydrocarbon, the thickener is a mixture of modified polyacrylamide and non-ionic polyurethane compound, and the film-forming aid is BYK, Germany The additive manufactured is BYK-194. The above raw materials are placed in a container to mix and stir (stirring cowpea is 450 rpm) to make a hydrosol.

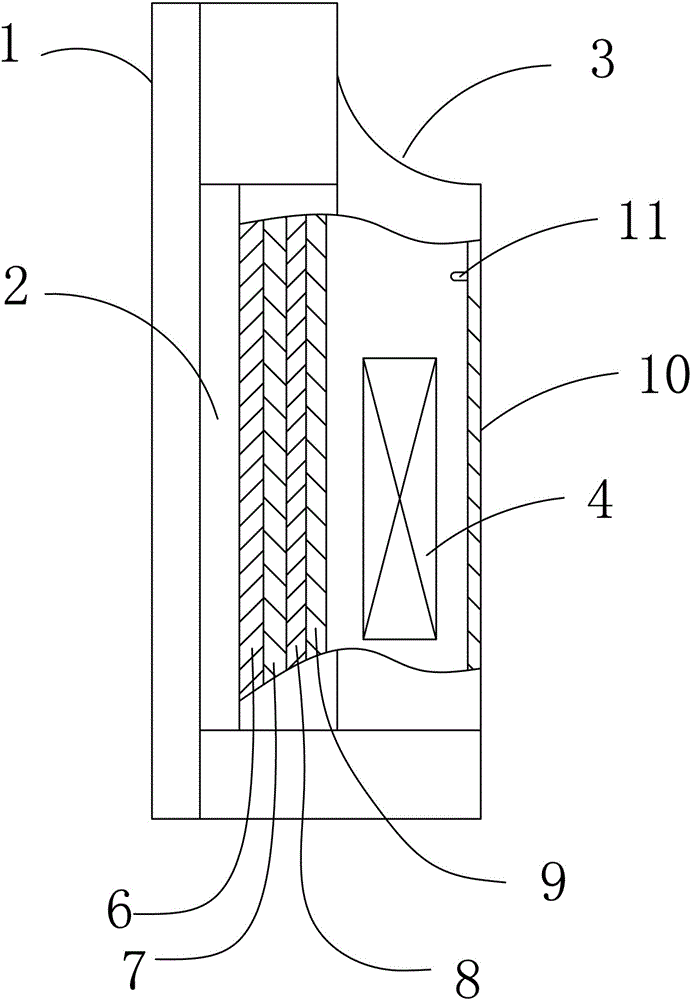

[0025] Soak the 400-mesh filter in the above-mentioned catalyst hydrosol and then dry it to make the catalyst layer adhere to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com