Method for preparing high specific surface area micron-scale spherical activated carbon from carboxymethyl cellulose

A carboxymethyl cellulose and spherical activated carbon technology, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve the problems of high chemical activation process intensity, easy corrosion equipment environment, high cost, and achieve green production process. The effect of environmental protection, improved use value and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

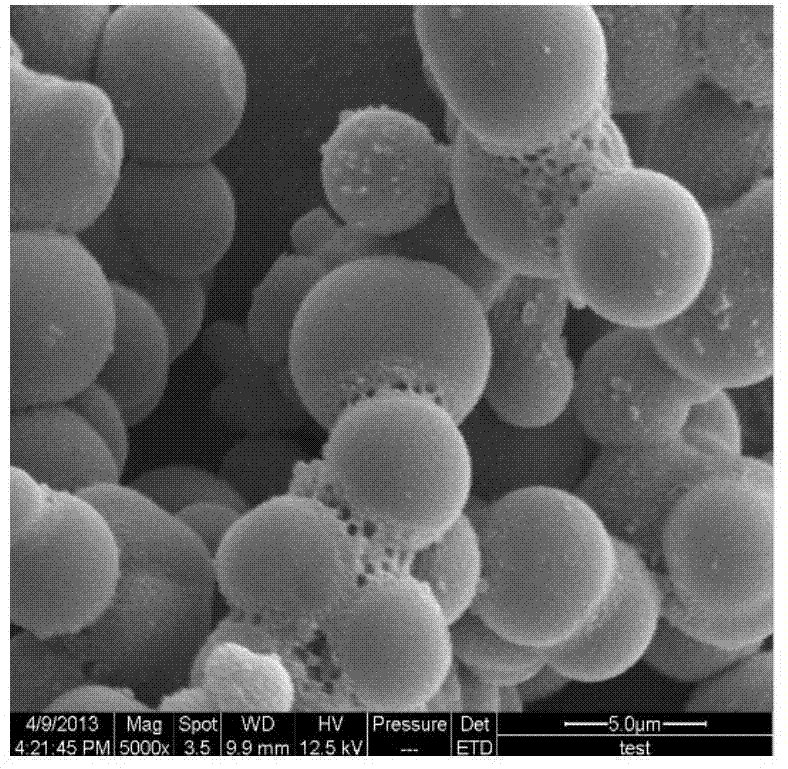

[0020] (1) 40mL carboxymethyl cellulose solution (1.5g40mL H 2 O) Ultrasonic vibration for 30min, transfer to a closed autoclave with a volume of 50mL of polytetrafluoroethylene, hydrothermal carbonization at 200°C for 10h, cool to room temperature, and pass through distilled water and absolute ethanol (content not less than 99.7%) ) was washed several times until the washing solution was clear, and the obtained black powder was dried at 105°C for 6 hours to obtain carbon sphere materials.

[0021] (2) Put carbon spheres as a precursor in a tube furnace in N 2 The temperature was programmed to rise to 800°C under protection, the heating rate was 5°C / min, and then the temperature was kept for CO 2 Activation, the activation time is 2h, pass N after activation 2 Cool naturally to room temperature to obtain spherical activated carbon.

[0022] (3) The BET specific surface area of spherical activated carbon is 637.64m 2 / g, the micropore specific surface area accounts for 77...

Embodiment 2

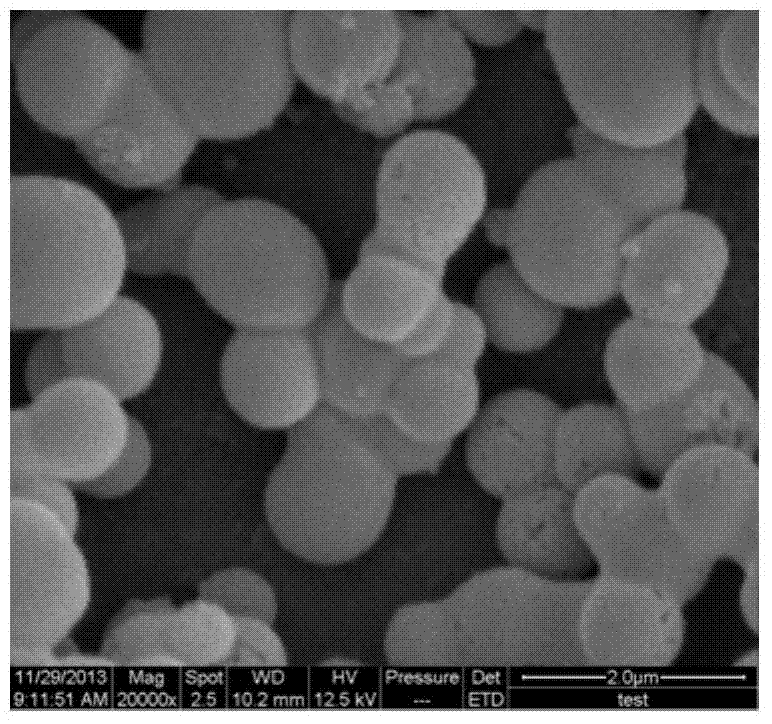

[0024] (1) 40mL carboxymethyl cellulose solution (1.5g40ml H 2 O) Ultrasonic vibration for 30min, transfer to a closed autoclave with a volume of 50mL of polytetrafluoroethylene, hydrothermal carbonization at 200°C for 10h, cool to room temperature, and pass through distilled water and absolute ethanol (content not less than 99.7%) ) was washed several times until the washing solution was clear, and the obtained black powder was dried at 105°C for 6 hours to obtain carbon sphere materials.

[0025] (2) Put carbon spheres as a precursor in a tube furnace in N 2 Under protection, the temperature was programmed to 850°C, the heating rate was 5°C / min, and then the temperature was maintained for CO 2 Activation, the activation time is 2h, pass N after activation 2 Cool naturally to room temperature to obtain spherical activated carbon.

[0026] The BET specific surface area of spherical activated carbon is 1005.85m 2 / g, the micropore specific surface area accounts for 68.07%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com