Method and system for recovering salt from waste water treatment system

A wastewater treatment system and wastewater technology, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of uneven separation and purification, complicated separation process, and difficult operation and adjustment. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

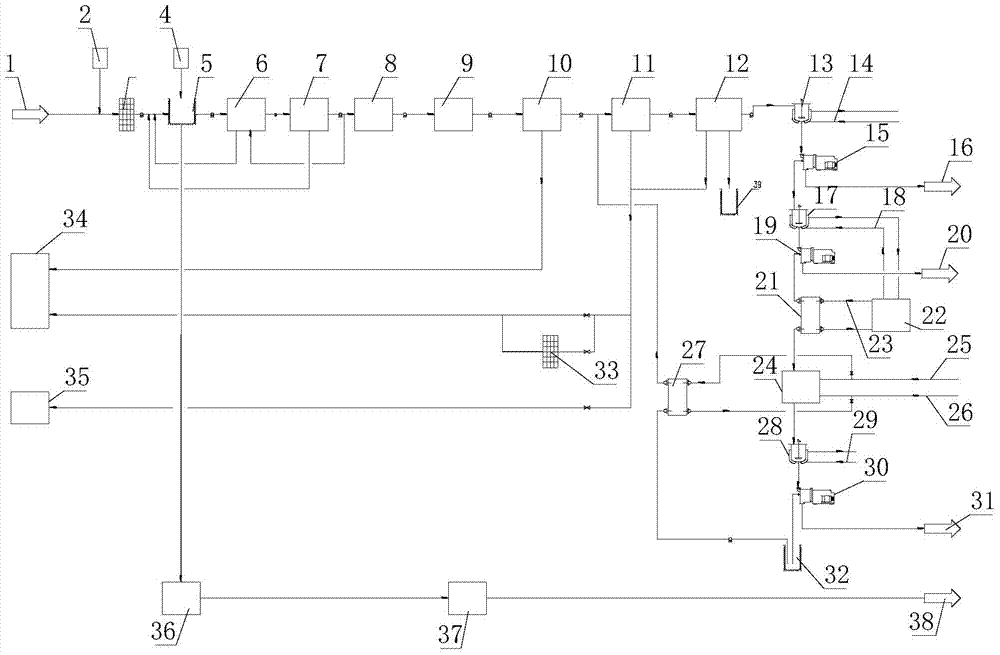

[0068] see figure 1 Shown is the system structure schematic diagram that reclaims salt from waste water treatment system, reveals that the concrete technological process of the present invention is as follows:

[0069](1) The waste water flows into the system from the waste water inflow (1), and a strengthened oxidant is cast (2) to oxidize the reducing substances in the waste water;

[0070] (2) Wastewater passes through the COD removal unit (3) to remove oxidized organic pollutants, nitrite, sulfide, ferrous salt and residual membrane scale inhibitor and NH 4 -N, etc., the COD removal unit adopts adsorption materials to remove COD, and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com