Image sensor and formation method thereof

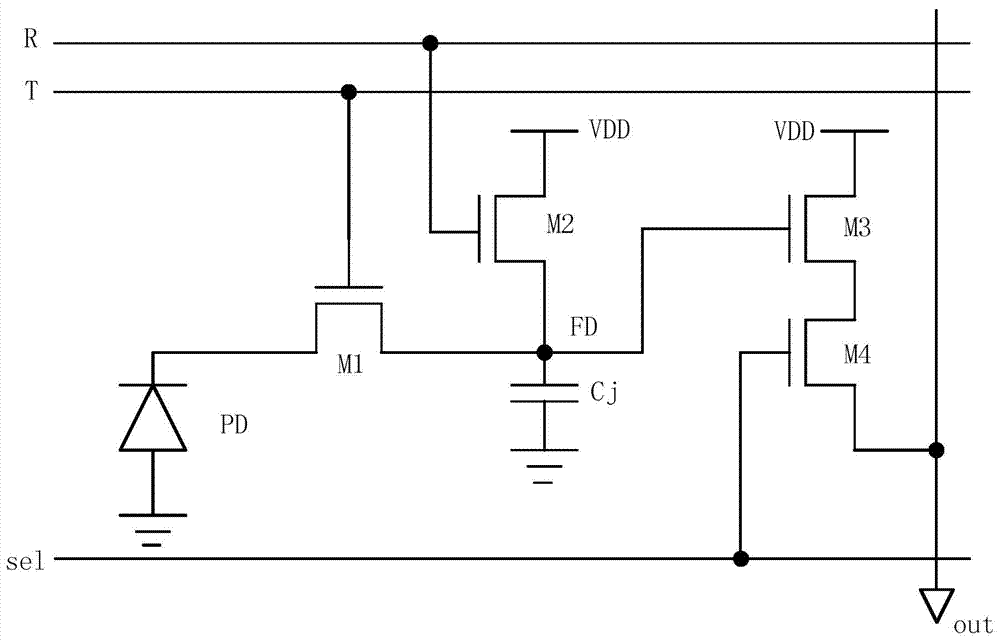

A technology of image sensor and pixel unit, which is applied in the semiconductor field to achieve the effect of reducing pixel area, improving performance, and increasing fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] As described in the background art, the performance of the existing image sensor needs to be further improved.

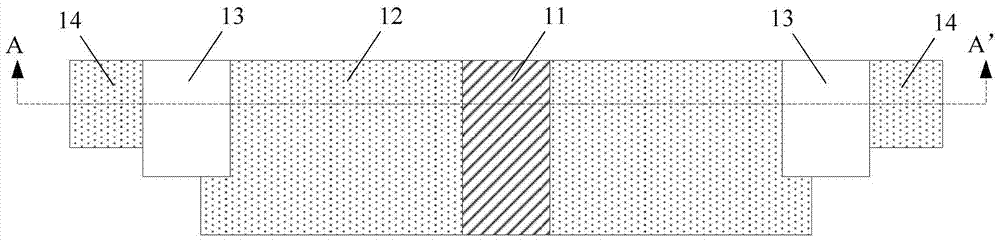

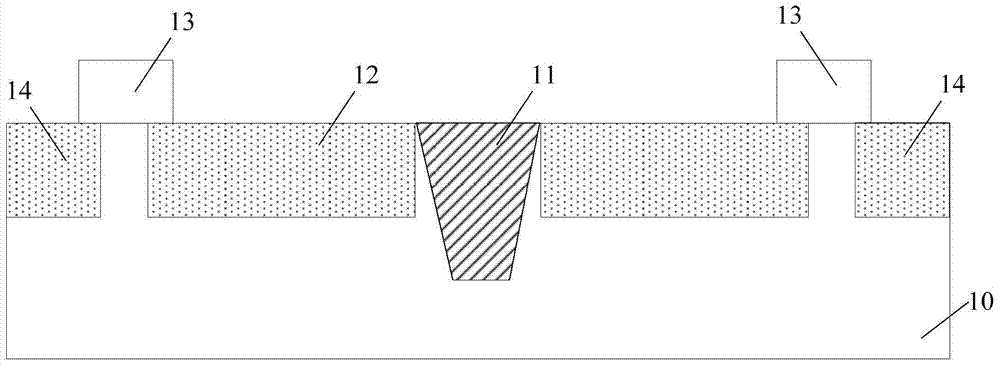

[0053] Please refer to figure 2 with image 3 , Are respectively a top view and a cross-sectional view of the photodiodes and transfer transistors of adjacent pixels located in the same row in the pixel array in the prior art, image 3 For the edge figure 2 A schematic cross-sectional view of the secant line AA'.

[0054] The image sensor unit includes a photodiode 12 in a semiconductor substrate 10, a gate structure 13 of a transfer transistor on the semiconductor substrate 10 on one side of the photodiode 12, and a semiconductor on the other side of the gate structure 13 The floating diffusion region 14 in the substrate 10. The pixel unit of the image sensor also includes other parts, such as: reset transistor, source follower transistor, row gate transistor, etc. figure 2 Part not shown in.

[0055] A shallow trench isolation structure 11 is formed in the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com