Packaging method for flexible-graphite-flake substrate LED

A flexible graphite sheet and LED packaging technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high price of ceramic materials, unsuitable for wide-scale promotion and use, and achieve good sealing, strong shock resistance and pressure resistance. sex, the effect of flexible use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

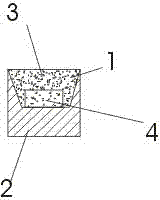

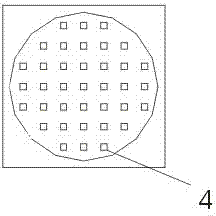

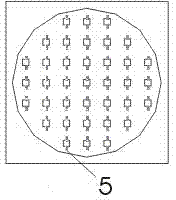

[0024] A flexible graphite sheet substrate LED chip and packaging method, using a flexible graphite sheet as a support, the packaging steps are:

[0025] A flexible graphite sheet substrate LED packaging method, using a flexible graphite sheet as a support, the packaging steps are:

[0026] (1) Crystal expansion: Use an expansion machine to evenly expand the entire LED wafer film, so that the LED grains that are closely arranged on the surface of the film are pulled apart to facilitate spinning;

[0027] (2) Dot primer: Dot insulating glue on the corresponding position of the graphite sheet;

[0028] (3) Solid crystal: Put the crystal expansion ring prepared with silver glue into the spinner frame, and the operator stabs the LED chip with a spinner pen on the corresponding position of the flexible graphite sheet under the microscope; (4) Baking : Put the stabbed flexible graphite sheet into a thermal cycle oven and let it stand at a constant temperature of 200°C for 5 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com