Polyester fiber cord for reinforcing rubber

A polyester fiber and rubber reinforced technology, applied in the direction of fiber type, fiber treatment, yarn, etc., can solve the problems of adhesive shedding, damage to the working environment, scattering, etc., and achieve the effect of good adhesion and improved process passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

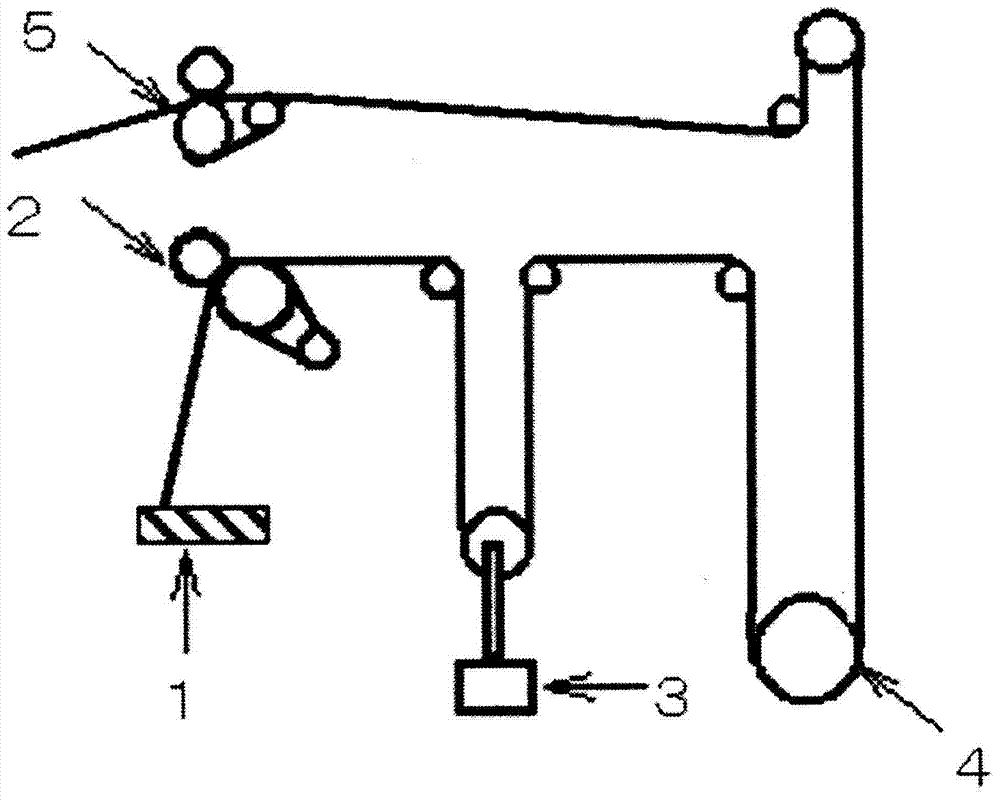

Method used

Image

Examples

Embodiment 1

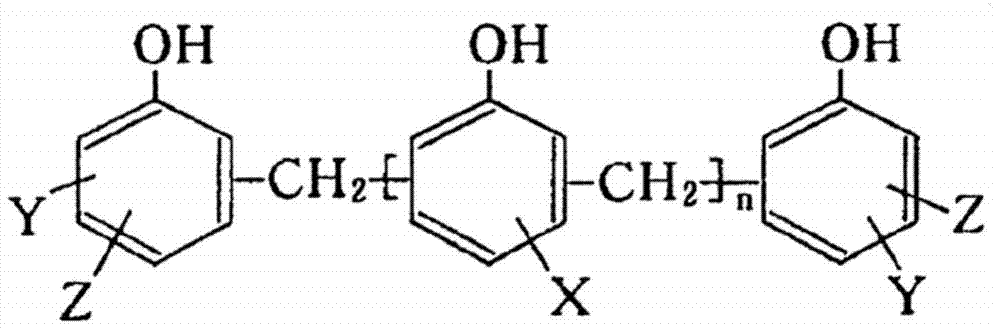

[0126] Add resorcinol-formaldehyde initial condensate: "Sumicanol" 700 (S)" (registered trademark) (manufactured by Sumitomo Chemical Co., Ltd., 65% aqueous solution) to an aqueous solution of sodium hydroxide, and stir sufficiently to disperse it. Formaldehyde was added to the dispersion and mixed uniformly, and as a result, the molar ratio of resorcinol / formaldehyde was 1 / 2, aged at 25° C. for 4 hours to obtain a solution of resorcinol-formaldehyde condensate. Then , 60 parts by mass of neoprene latex ("ショウプレン" (registered trademark) 750 (produced by Showa Denko, surface tension 39mN / m, average particle diameter 120nm) and 40 parts by mass of polybutadiene rubber latex ("ニッポール " (registered trademark) LX-111A (manufactured by Nippon Zeon Co., Ltd., average particle diameter 300nm) was mixed to prepare a rubber latex mixed solution. The aforementioned rubber latex mixed solution was mixed with the aforementioned resorcinol-formaldehyde condensate solution , so that the solid c...

Embodiment 2~10、 comparative example 1~6

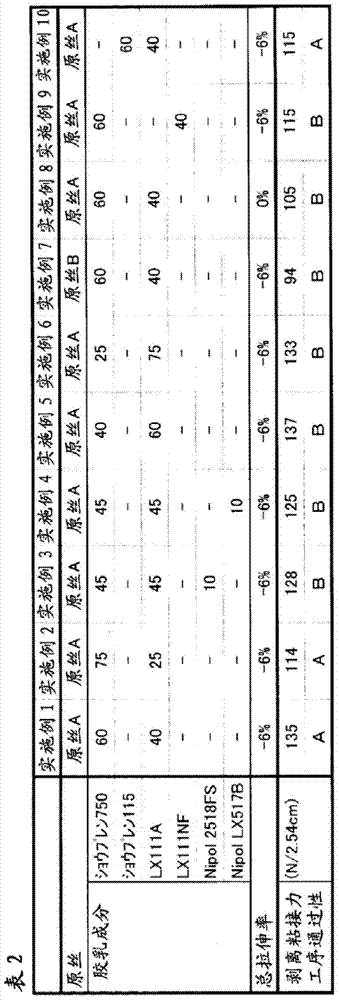

[0131] The treatment was performed under the same conditions as in Example 1 except that the raw yarn, latex, and total elongation used in Example 1 were changed as shown in Tables 2 and 3, and evaluation was performed in the same manner. The evaluation results are summarized in Tables 2 and 3 and shown.

[0132] Table 2

[0133]

[0134] ショウプレン750: Neoprene latex "Shoupren" (registered trademark) 750 (manufactured by Showa Denko Co., Ltd.)

[0135] ショウプレン 115: Neoprene latex "ショウプレン" (registered trademark) 115 (manufactured by Showa Denko Co., Ltd.)

[0136] LX111A: Polybutadiene rubber latex "ニッポール" (registered trademark) LX-111A (manufactured by Nippon Zeon Co., Ltd.)

[0137] LX111NF: Polybutadiene rubber latex "ニッポール" (registered trademark) LX-111NF (manufactured by Nippon Zeon Co., Ltd.)

[0138] Nipol 2518FS: Vinylpyridine-styrene-butadiene rubber latex "ニッポール" (registered trademark) 2518FS (manufactured by Nippon Zeon Co., Ltd.)

[0139] Nipol LX517B: Acrylonitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com