Edible blending oil with balanced nutrients and production method thereof

A technology for blending oil and nutrition, applied in the fields of edible oil/fat, application, food science, etc., can solve the problem of being unsuitable for the elderly to eat, and achieve the effect of reducing cardiovascular and cerebrovascular diseases and ensuring demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

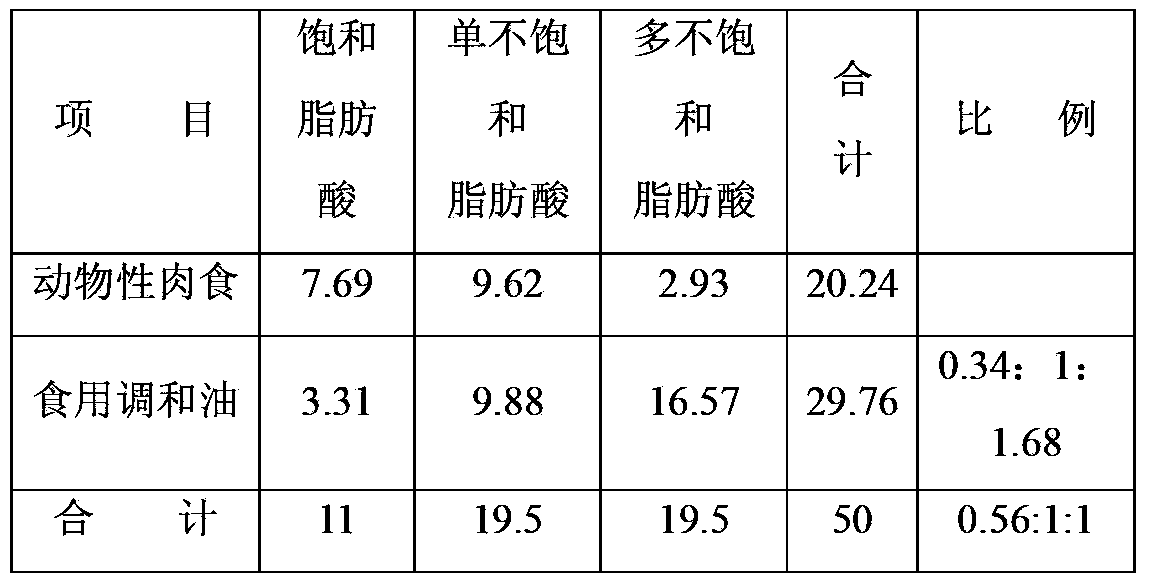

Embodiment 1

[0039] 142kg of linseed oil, 355kg of corn oil, 154kg of olive oil, 290kg of walnut oil, and 59kg of sesame oil were refined and stored in tanks for later use; various vegetable oils were accurately weighed according to different formulas, and 0.5% vitamin E and / or add 0.3% tea polyphenols into the batching tank, keep the temperature at 20°C-40°C, stir evenly and slowly for 20-40 minutes, filter and fill to obtain nutritionally balanced blended oil product oil.

Embodiment 2

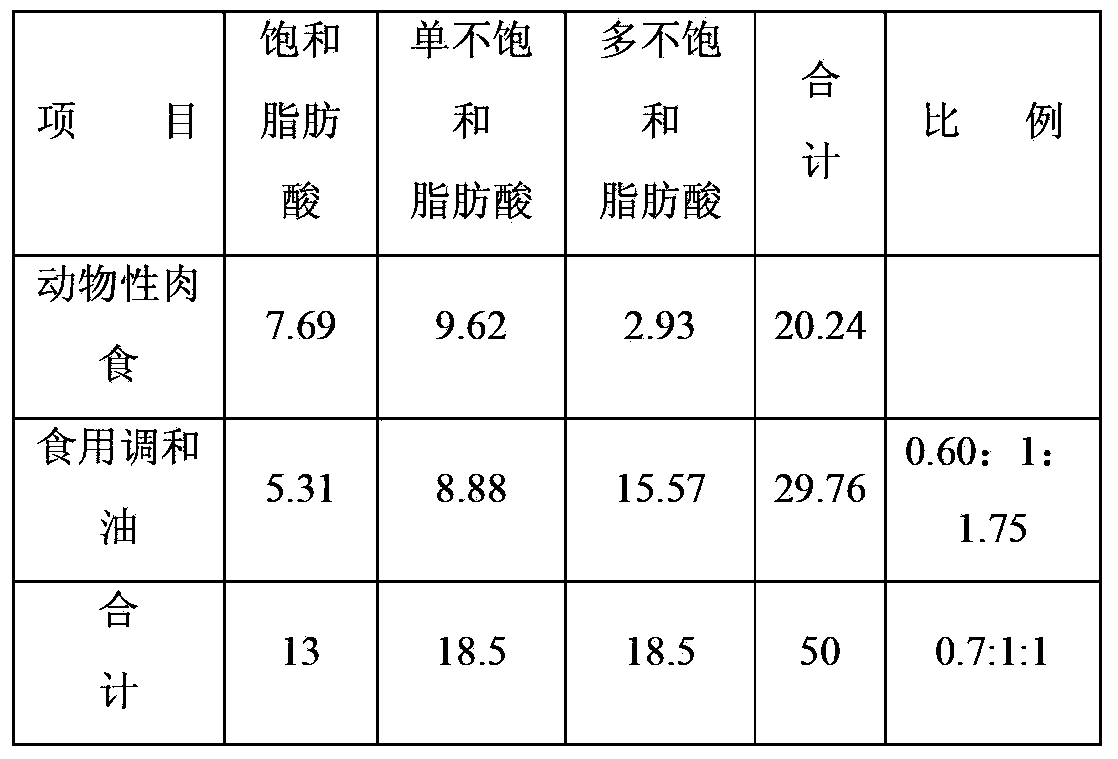

[0041]80kg of linseed oil, 400kg of soybean oil, 305kg of walnut oil, 140kg of camellia oil, and 75kg of canola oil were refined and stored in tanks for later use; various vegetable oils were accurately weighed according to different formulas, and 0.5% of the total vegetable oil quality was equivalent to Add % vitamin E and / or 0.3% tea polyphenols into the batching tank, keep the temperature at 20°C-40°C, stir evenly and slowly for 20-40 minutes, filter and fill to obtain nutritionally balanced blended oil product oil.

Embodiment 3

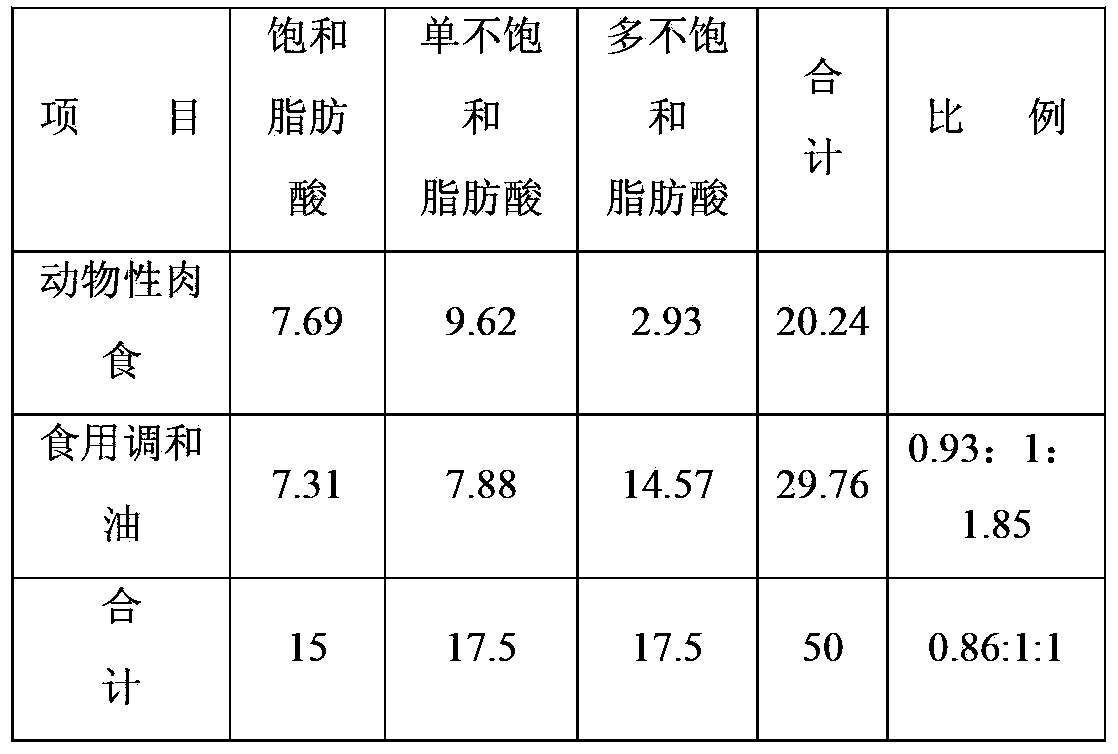

[0043] Refining 100kg linseed oil, 168kg hemp seed oil, 103kg rapeseed oil, 374kg sunflower oil and 255kg Camellia oleifera seed oil respectively and storing them in tanks for later use; Accurately weigh various vegetable oils according to different formulas, and the amount equivalent to the total vegetable oil quality Add 0.5% vitamin E and / or 0.3% tea polyphenols to the batching tank, keep the temperature at 20°C-40°C, stir evenly and slowly for 20-40 minutes, filter and fill to obtain nutritionally balanced blended oil and finished oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com