Casting cleaning, polishing and dedusting all-in-one equipment

A casting cleaning and equipment technology, used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of increased production cost, high resistance of the pipe network, large floor space, etc., and achieves reduced operating costs and emission concentration. Low, small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

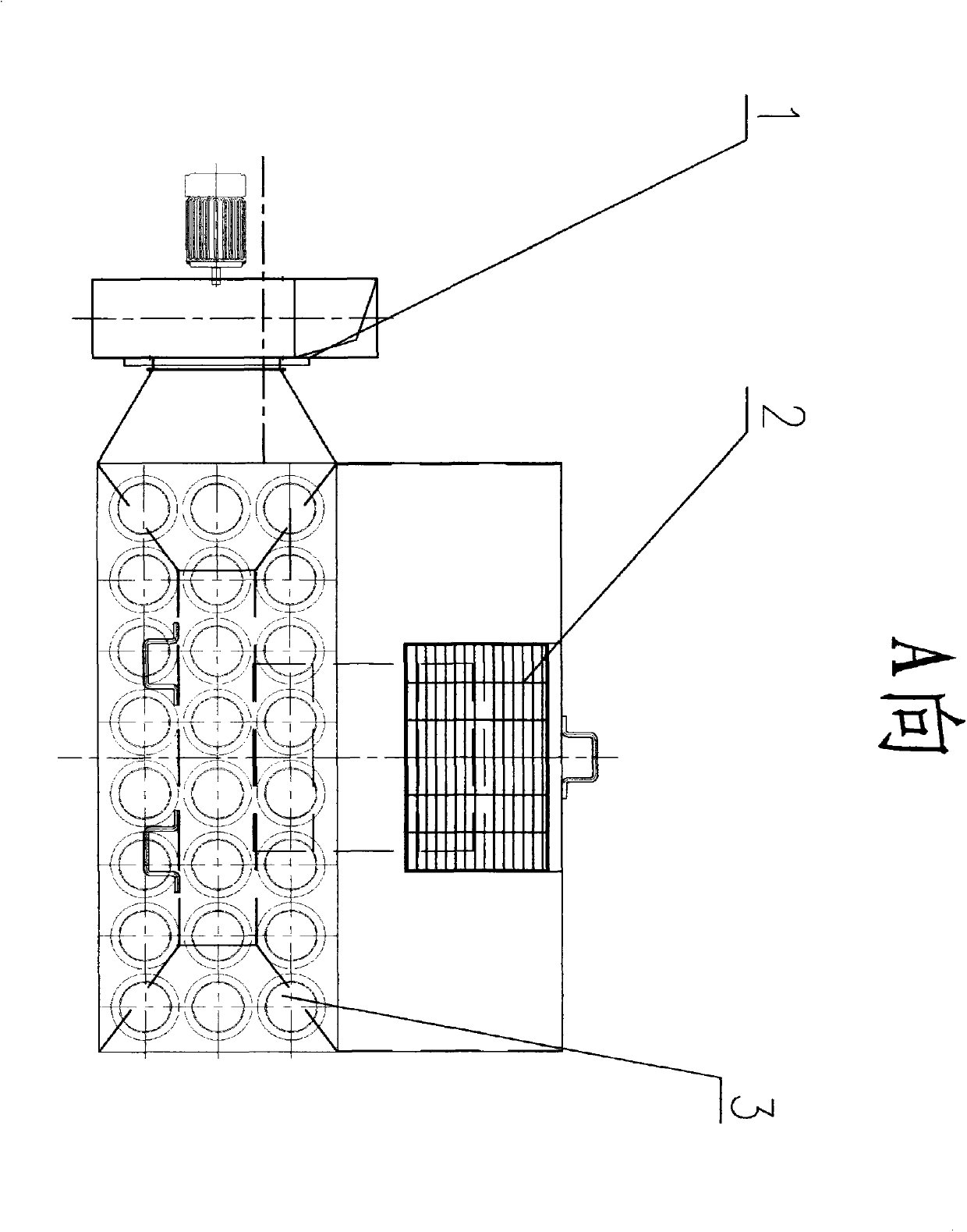

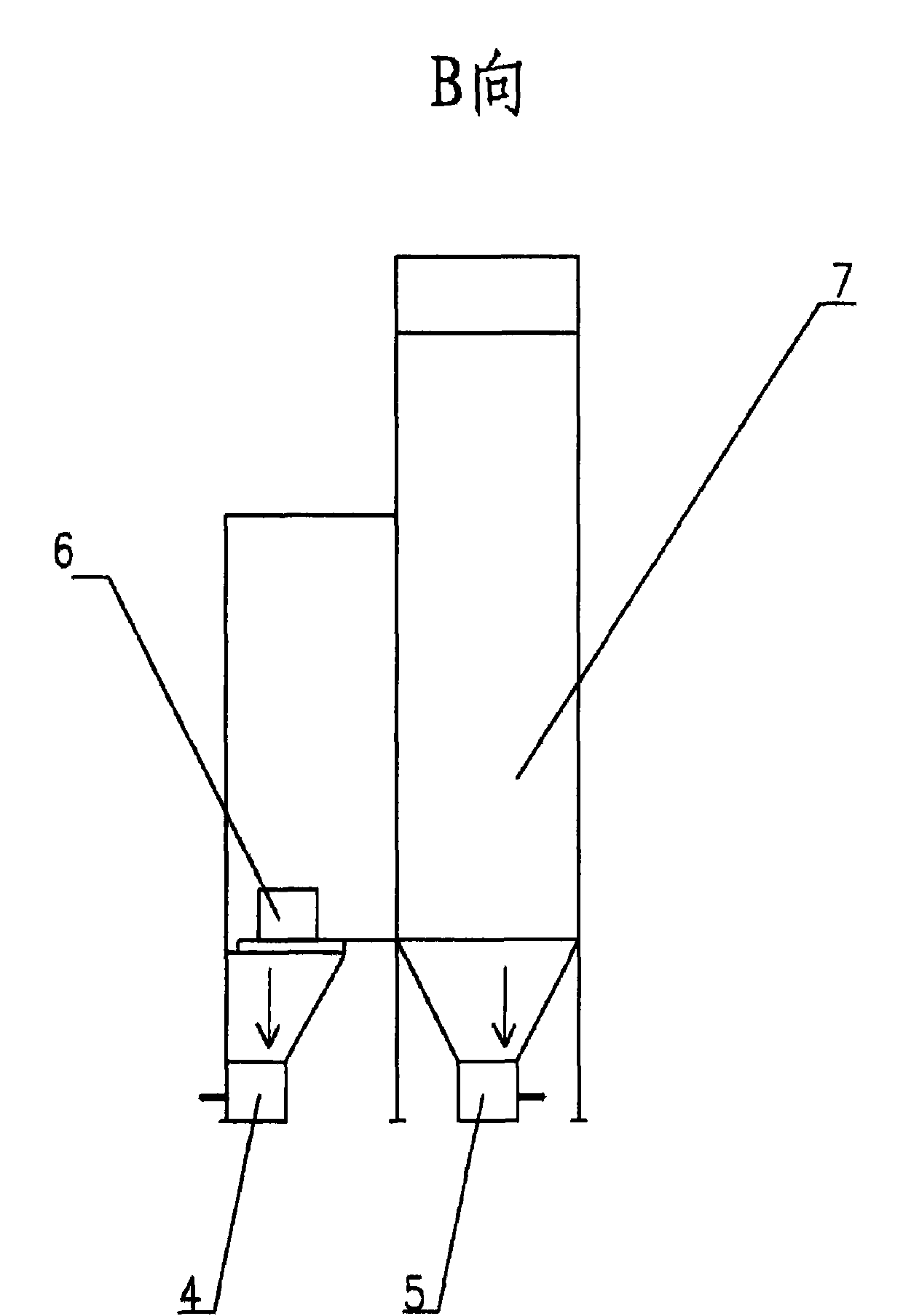

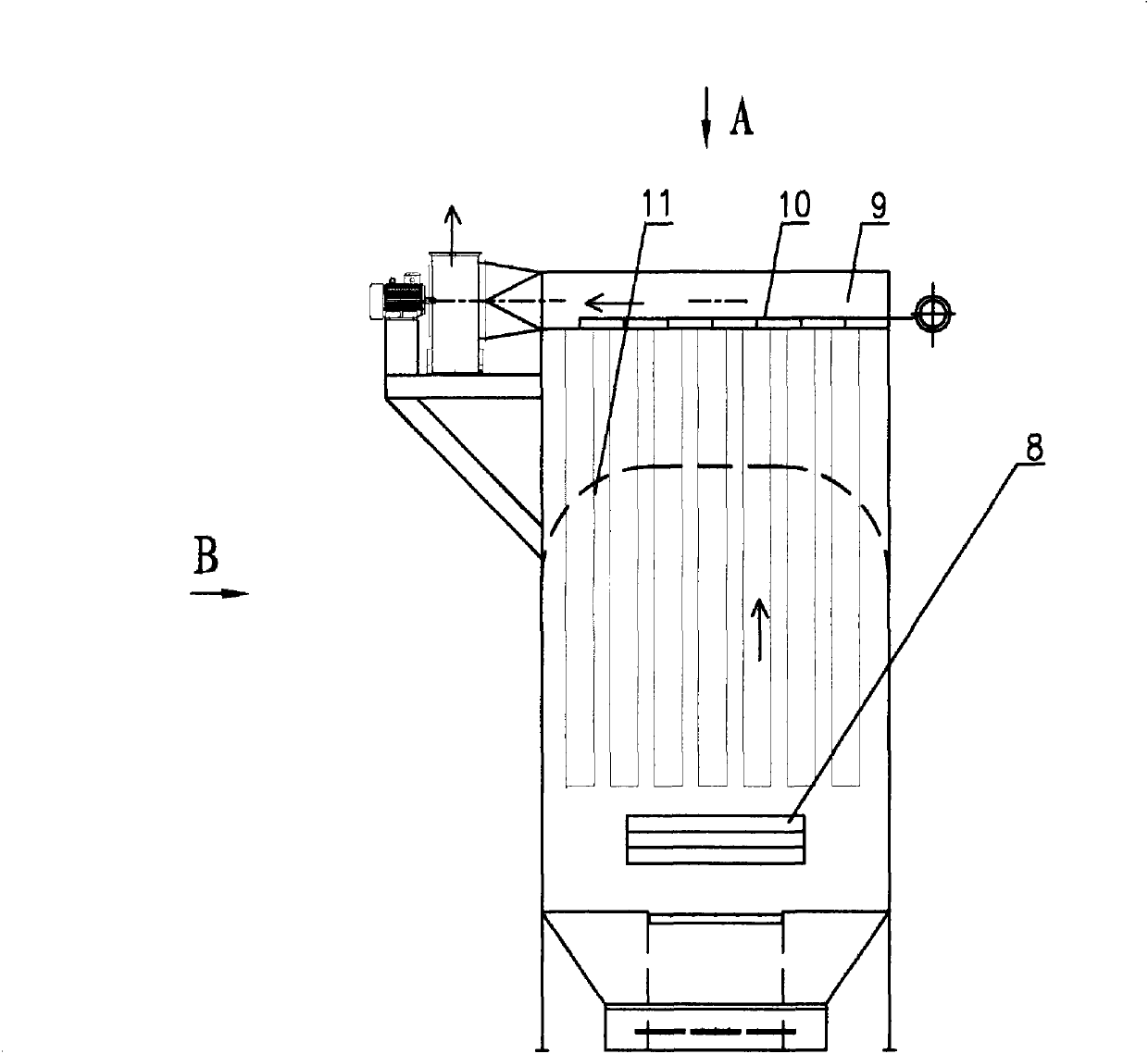

[0011] Such as figure 1 , figure 2 , image 3 As shown, the present invention is an integrated equipment for cleaning, grinding and dust removal of castings, which includes a grid workbench 2, a bag filter chamber 7, and a fan 1, and is characterized in that: the grid workbench 2 is sequentially connected to the bag filter chamber 7, fan 1. The top of the grid workbench 2 is a trapping cover 11, the bottom of the grid workbench 2 is a coarse particle waste collector 4, and the connection plate between the grid workbench 2 and the bag filter chamber 7 is provided with an air suction port 8, The bag filter chamber 7 is provided with a filter bag 3, the material of the filter bag 3 is water-repellent and oil-proof polyester needle-punched felt, the bottom of the bag filter chamber 7 is a fine particle waste collector 5, and the top of the bag filter chamber 7 is a clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com