Extruder filter system and application thereof

A filtration system and extruder technology, applied in the field of filtration systems, can solve the problems of incomplete cleaning of filter net impurities, reduced filter life, impact on the production process, etc., so as to shorten the cleaning time, smooth the extrusion process, and effectively heat energy. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

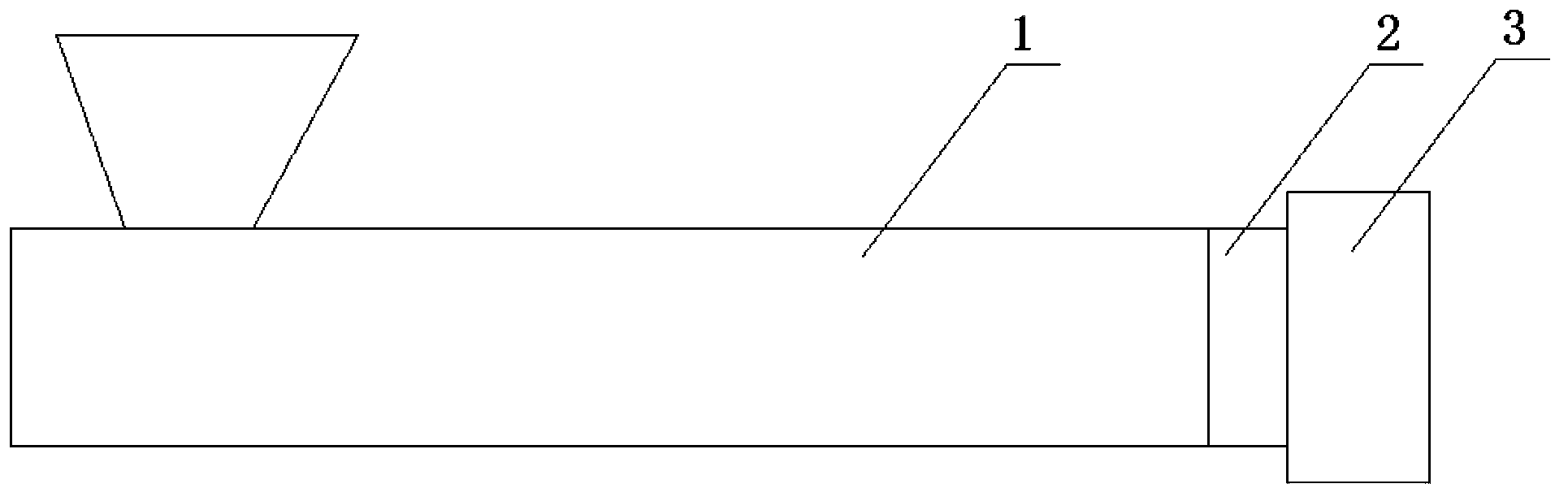

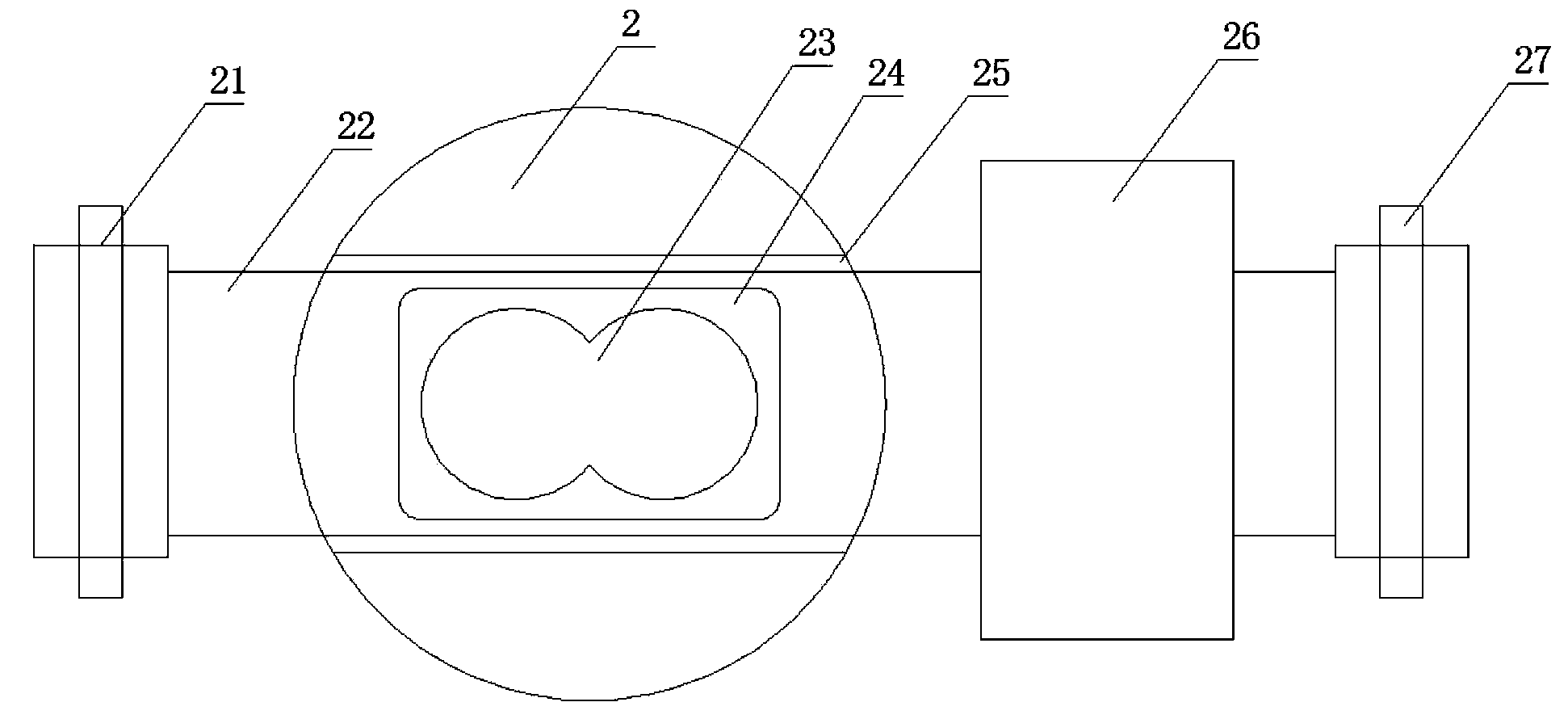

[0040]A kind of extruder filter system that is used to reclaim polyethylene, this filter system comprises the filter body 2 that is connected with extruder barrel 1 and extruder die head 3, filter screen plate 24, continuous filter screen 22 and filter Net traction system 27, the filter body 2 is connected to the tail of the extruder barrel 1, between the extruder barrel 1 and the extruder die 3, the filter screen 24 is arranged in the filter body 2 , the shape is matched with the extruder runner 23, the filter body 2 has a filter screen channel 25 on both sides, the continuous filter screen 22 enters the filter body 2 through the filter screen channel 25, passes through the filter screen plate 24, and passes through the filter screen plate 24 from the other side The outlet filter body 2 is connected with the filter net traction system 27, and the filter net traction system 27 drags the continuous filter net 22 to move in the filter body 2.

[0041] The overall shape of the fi...

Embodiment 2

[0047] A kind of extruder filter system that is used to reclaim polyethylene, this filter system comprises the filter body 2 that is connected with extruder barrel 1 and extruder die head 3, filter screen plate 24, continuous filter screen 22 and filter Net traction system 27, the filter body 2 is connected to the tail of the extruder barrel 1, between the extruder barrel 1 and the extruder die 3, the filter screen 24 is arranged in the filter body 2 , the shape is matched with the extruder runner 23, the filter body 2 has a filter screen channel 25 on both sides, the continuous filter screen 22 enters the filter body 2 through the filter screen channel 25, passes through the filter screen plate 24, and passes through the filter screen plate 24 from the other side The outlet filter body 2 is connected with the filter net traction system 27, and the filter net traction system 27 drags the continuous filter net 22 to move in the filter body 2.

[0048] The filter screen cleaning...

Embodiment 3

[0059] An extruder filter system for recycling waste polystyrene plastics, the filter system includes a filter body connected to the extruder, a filter screen plate, a continuous filter screen and a filter screen traction system, the filter body Connected to the tail of the extruder barrel, the filter plate is set in the filter body, and its shape matches the flow channel of the extruder. There are filter channels on both sides of the filter body, and the continuous filter enters the filter through the filter channel. The body passes through the filter plate, and the filter body is connected with the filter traction system from the other side, and the filter traction system pulls the continuous filter to move in the filter body.

[0060] The filter net is provided with a filter net cleaning device on the side where the filter net exits from the filter net channel on the side of the filter body; the filter net cleaning device includes the following components: a cleaning device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com