Reclaimed water recycling intelligent integrated device capable of implementing zero sewage discharge and application thereof

A zero-discharge, reclaimed water technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of reducing equipment use costs, good effluent quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

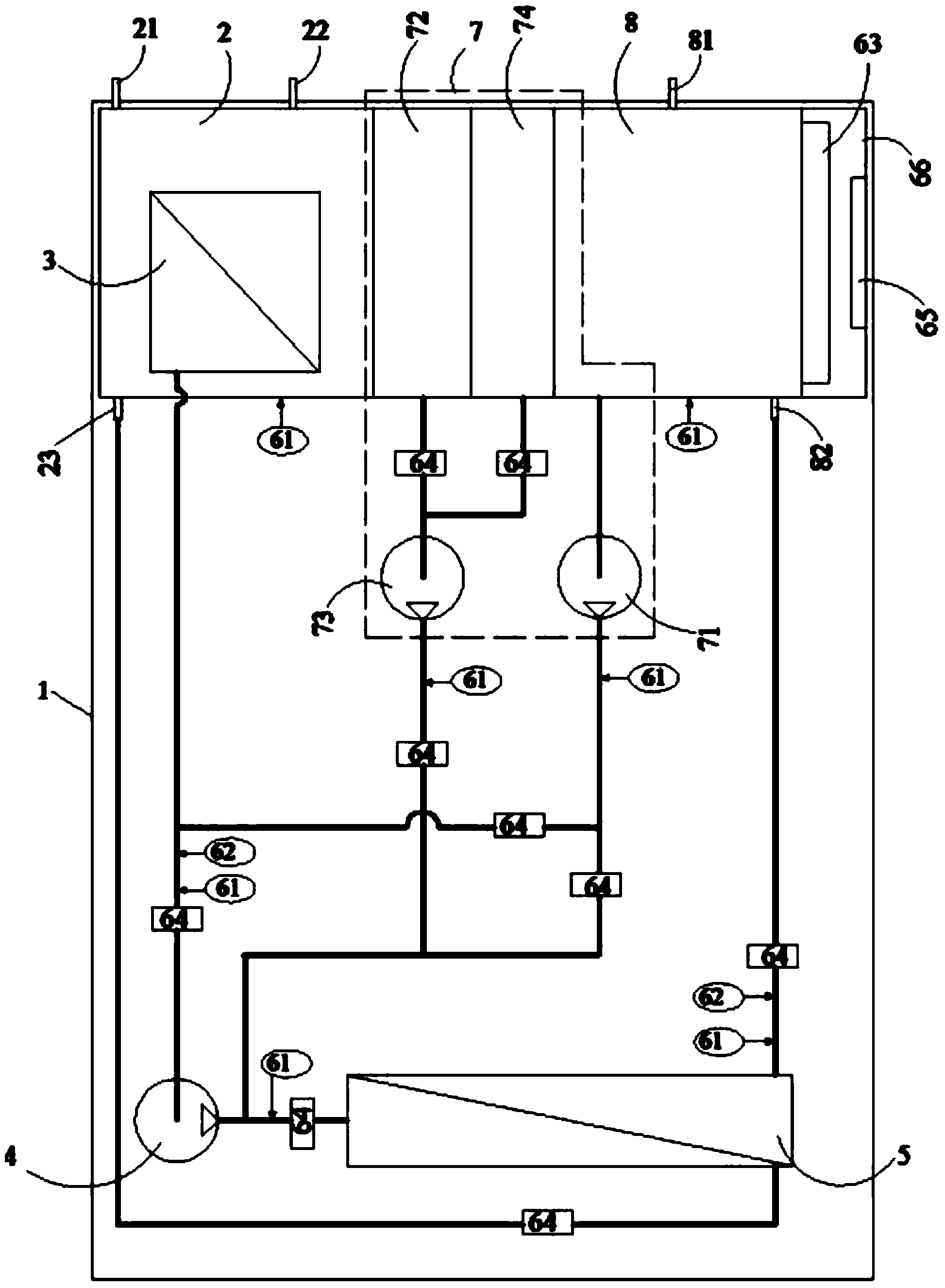

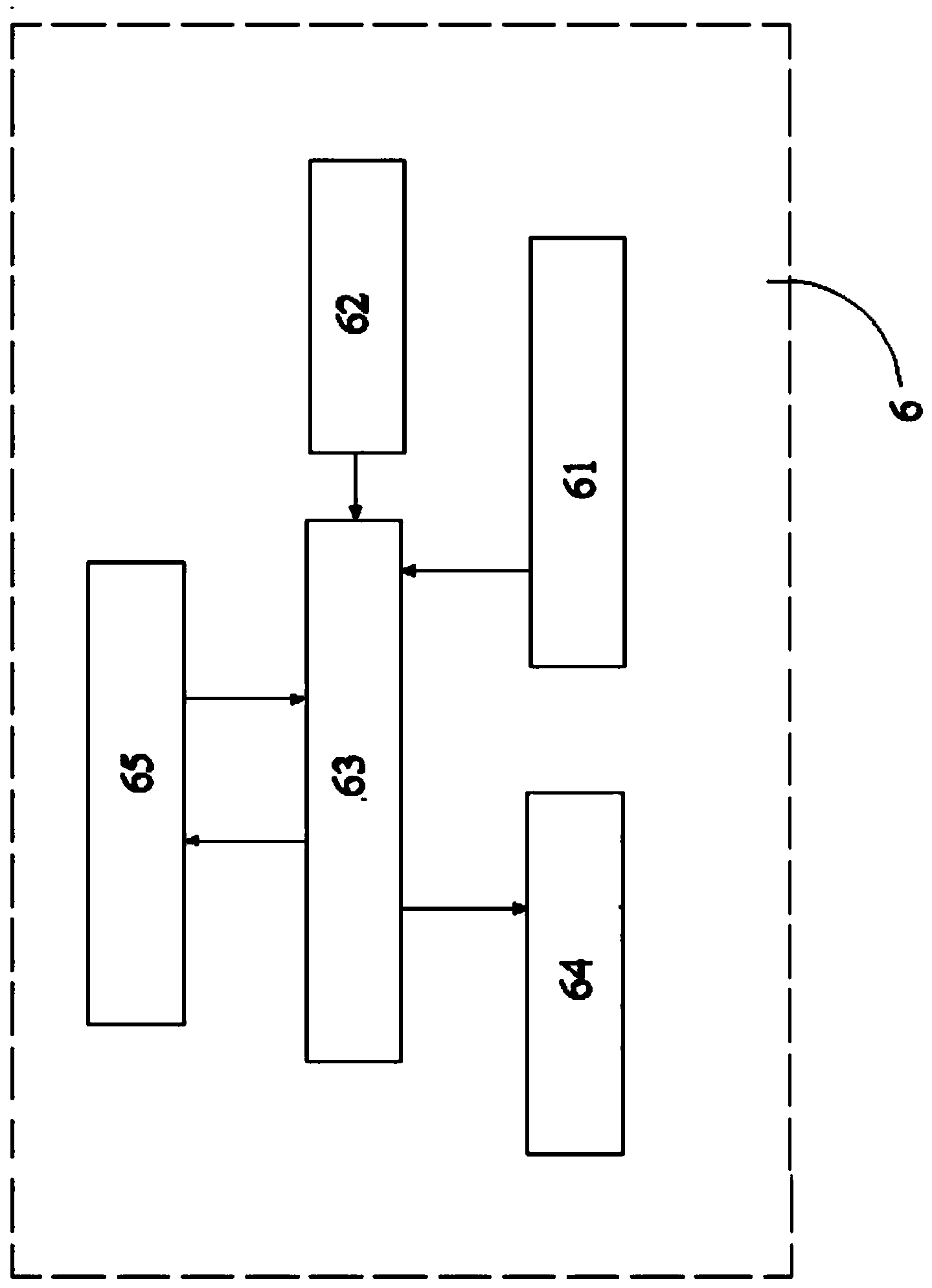

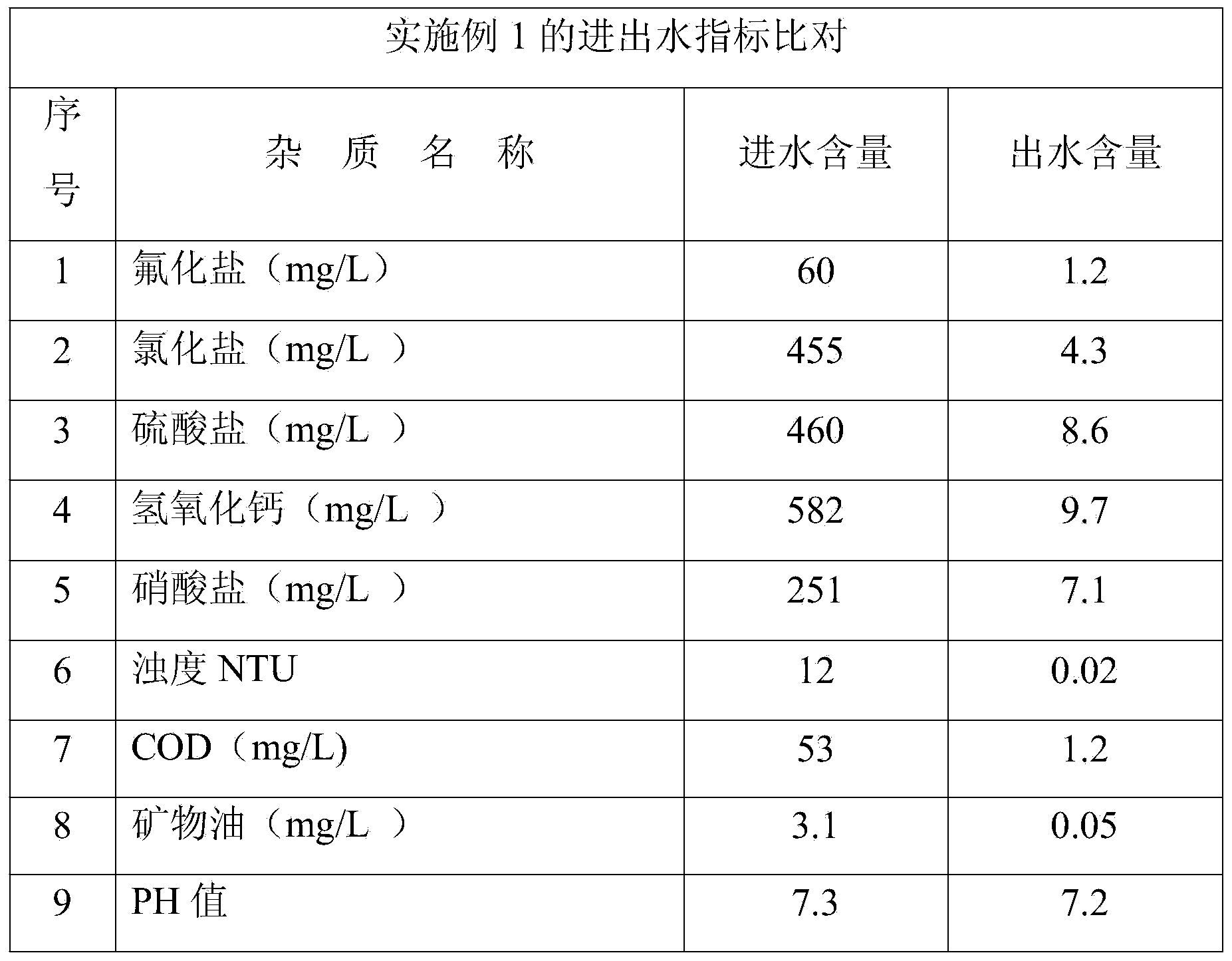

[0066]The equipment of this embodiment includes a rack 1 , a water inlet tank 2 , a submerged ultrafiltration membrane group 3 , a membrane pump 4 , a reverse osmosis membrane group 5 , an automatic control system 6 , a membrane maintenance system 7 and a pure water tank 8 . The frame 1 includes a base plate (not shown in the figure) and a mounting frame (not shown in the figure); the base plate is provided with a water inlet tank 2 , a membrane pump 4 , a reverse osmosis membrane group 5 and an automatic control system 6 . The water inlet 2 is provided with a water inlet 21, a water return port 22 and a concentrated water inlet 23; the water inlet 21 is used to connect the reclaimed water, and the water return port 22 is used to return the concentrated water filtered by the submerged ultrafiltration membrane group to the original reclaimed water system, the concentrated water inlet 23 is used to connect the concentrated water of the reverse osmosis membrane. The submerged ult...

Embodiment 2

[0072] The equipment of this embodiment is substantially the same as the equipment of Embodiment 1, except that the reverse osmosis membrane group 5 is composed of a single-stage reverse osmosis membrane.

[0073] This embodiment is used for the reuse of reclaimed water in the treatment of printing and dyeing wastewater. The wastewater is alkaline wastewater, which has been pretreated by alkali recovery, neutralization, flocculation, sedimentation, biochemistry, sedimentation, etc., and has reached the discharge standard. In order to reduce wastewater discharge, All to be reused.

[0074] The supernatant liquid from the pretreatment sedimentation tank is connected to the equipment, and enters the water inlet tank 2 through the water inlet interface 21. Under the program control of the automatic control system 6, the membrane pump 4 is used as the power to make the reclaimed water pass through the submerged supernatant. The filter membrane group 3 and the reverse osmosis membra...

Embodiment 3

[0078] The equipment of this embodiment is basically the same as the equipment of Embodiment 1, except that the reverse osmosis membrane group 5 is composed of two-stage reverse osmosis membranes connected in series.

[0079] This embodiment is used for reuse of reclaimed water in landfill leachate treatment. Landfill leachate is a kind of high-concentration organic wastewater with complex components, which has been pretreated by biochemical and precipitation; If the discharge cannot meet the standard, it is planned to be reused.

[0080] The supernatant liquid from the pretreatment sedimentation tank is connected to the equipment, and enters the water inlet tank 2 through the water inlet interface 21. Under the program control of the automatic control system 6, the membrane pump 4 is used as the power to make the reclaimed water pass through the submerged supernatant. The filter membrane group 3 and the reverse osmosis membrane group 5 separate various impurities, upgrade the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com