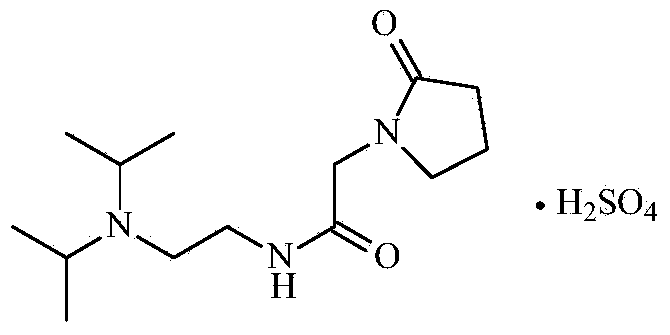

Preparation method of Pramiracetam sulfate

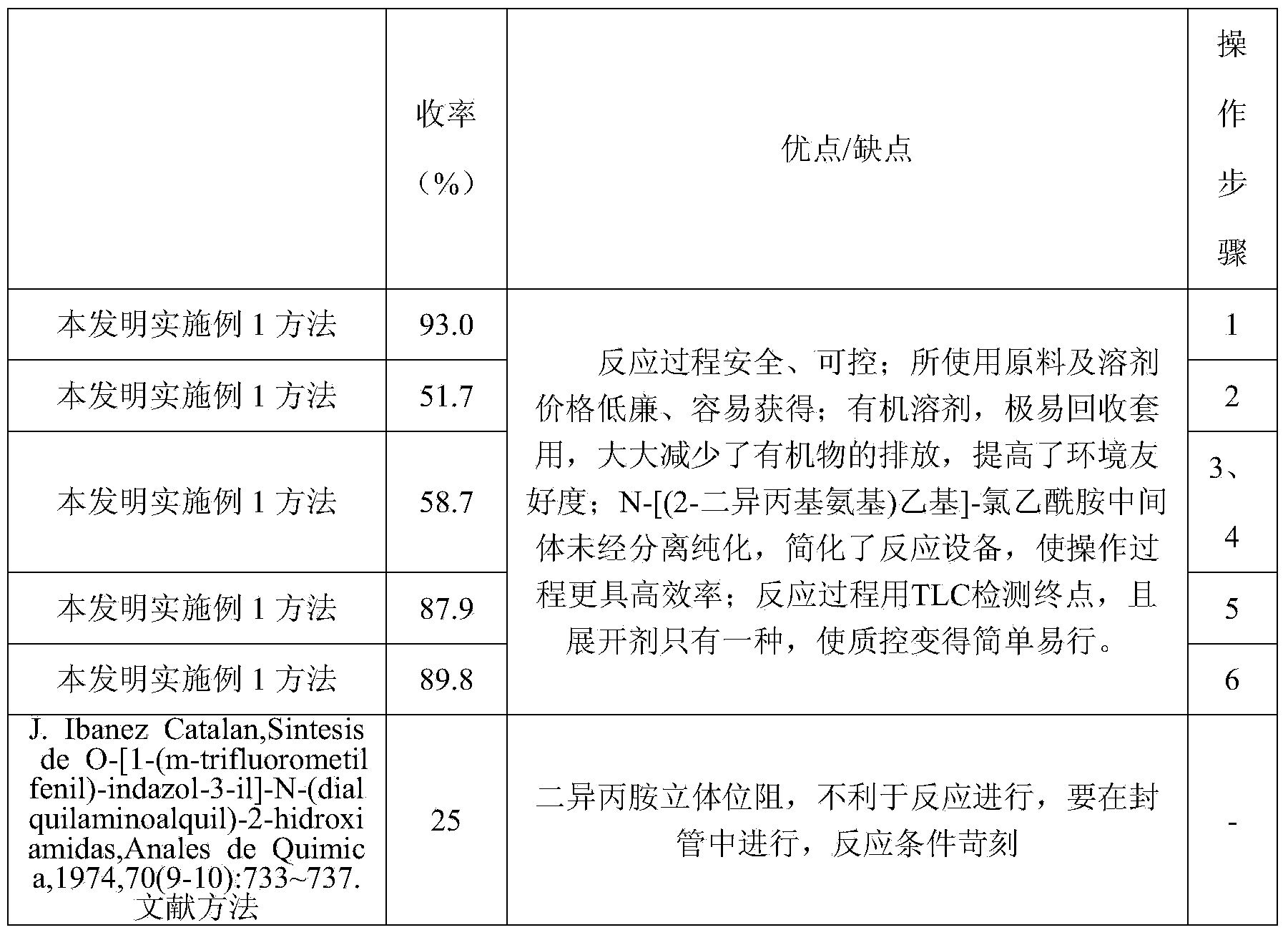

A technology for pramiracetam sulfate and chloroethylamine hydrochloride, which is applied in the field of preparation of pharmaceutical compounds, can solve the problems of many by-products, increase one-step reaction, and high temperature, achieve easy availability, improve environmental friendliness, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

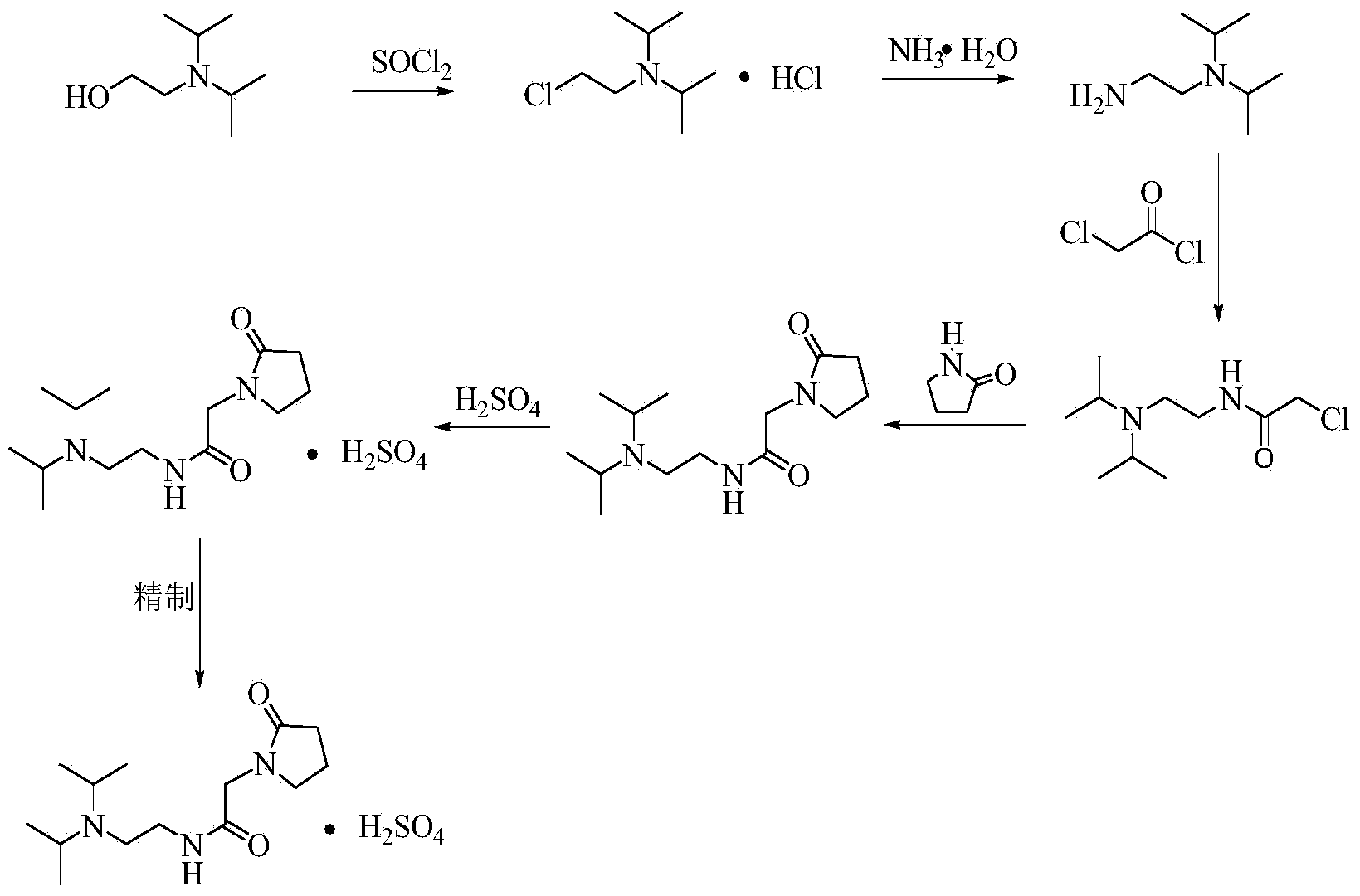

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of N,N-diisopropyl-2-chloroethylamine hydrochloride

[0045] Add 40.95kg of thionyl chloride into a 100L reaction kettle, stir mechanically, cool in an ice-salt bath, and drop the temperature in the reaction kettle to 0-5°C, slowly add 25.00kg of N,N-diisopropylethanolamine dropwise, After the addition, the temperature was raised to 75-80° C. to continue the reaction for 10 h, and the reaction was detected by TLC (developing solvent: dichloromethane: methanol: ammonia water = 20:4:1, iodine color development). When the inner temperature of the reaction kettle drops to 30-40°C, slowly add 5.52 kg of methanol under the condition of mechanical stirring. Then the temperature was controlled at 55-60°C, and distillation was performed under reduced pressure to obtain a reddish-brown solid; 22.00 kg of ethanol / isopropyl ether (1:10) mixed solvent was added, stirred and crystallized at 0-5°C for 10 hours, and dried with a centrifuge to obtain Pale yellow solid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com