Method for expressing gamma/gamma' phase crystal lattice mismatching degree in nickel-based high-temperature alloy

A technology of nickel-based superalloy and lattice mismatch, which is applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of expensive, complicated and cumbersome sample preparation, and achieve simple sample preparation, convenient operation, and reduced errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

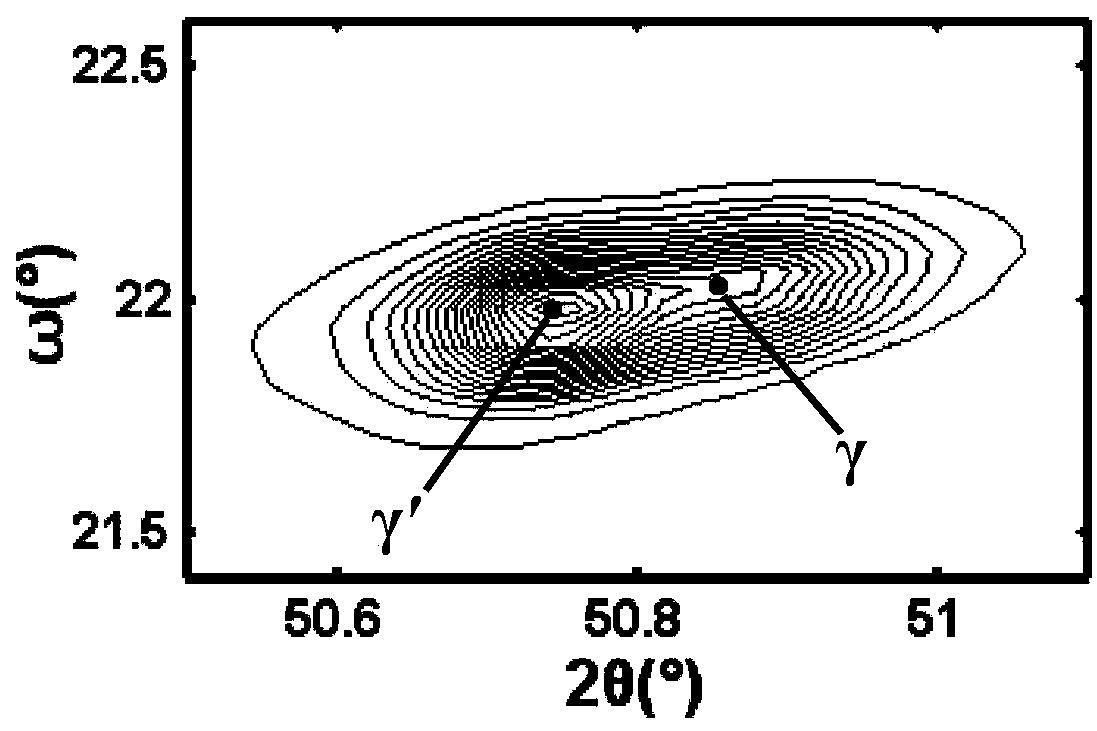

[0041] The directionally solidified DD483 (C 0.07, Cr 12.26, Mo 1.99, Co 9.19, W 3.76, Al 3.48, Ti 4.00, Ta 4.86, B 0.015, other Ni, wt.%) single crystal superalloy was tested and characterized by this method. The lattice mismatch degree of the γ / γ' phase, the test and characterization process is as follows:

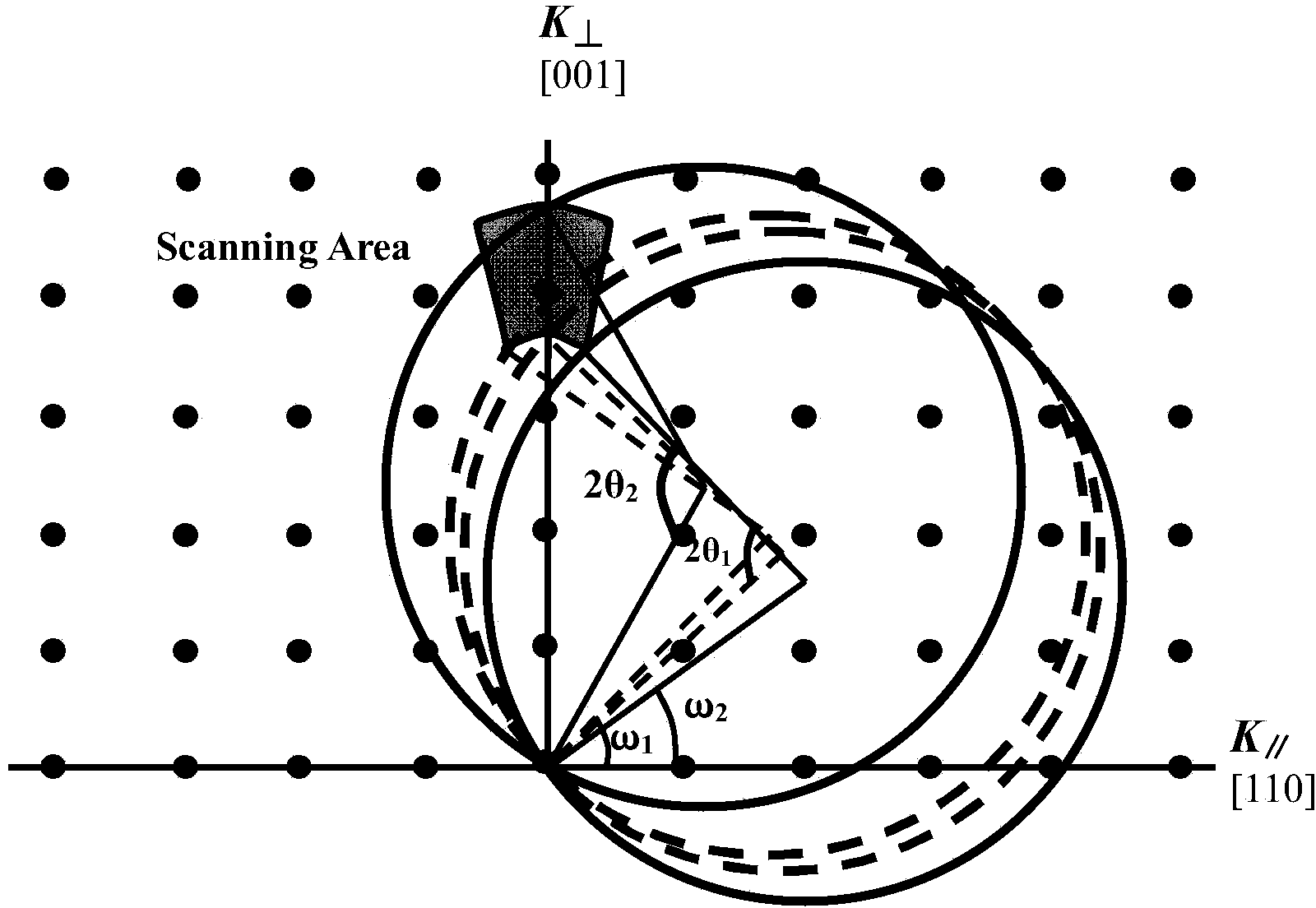

[0042] S1 first conducts θ-2θ linkage scanning on the sample, the scanning step is 0.002°, and the scanning speed is 0.25° / min, and the diffraction range of the (002) plane of the crystal is determined to be 50° to 52°;

[0043] S2 then equally divides the detector 2θ angle range (50-52°) with a step size of 0.02°, that is, 100 equal parts;

[0044] S3 fixes the 2θ angle, performs ω scan, sets the range of ω angle (rotation angle of the sample stage) to ±2°, the step size is 0.008°, and the scanning speed is 4° / min; record ω, 2θ and intensity values;

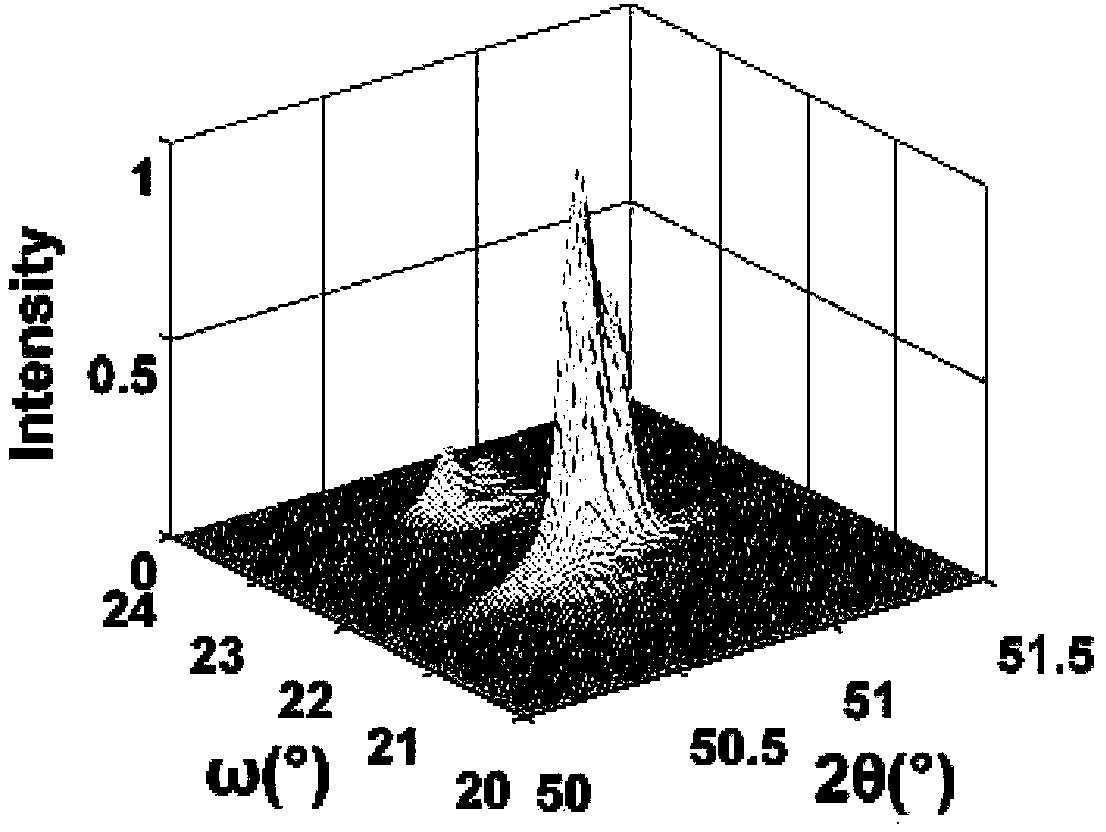

[0045] S4 normalizes the diffraction intensity, imports the three sets of data into matlab software, and obtains the co...

Embodiment 2

[0070] This method is used to test and characterize the lattice mismatch degree of γ / γ' phase in the heat-treated DD483 single crystal superalloy. The heat treatment system is 1,204℃ / 1h+1,265℃ / 1h / air cooling+1,084℃ / 4h / furnace cooling, The test characterization process is the same as that in Example 1, and the test results are shown in Table 2. In the alloy of this embodiment, the amount of Cr+Co+Mo reaches 23.44wt%, while the content of Ta+W is 8.62wt%, so the heat treatment process makes the amount of alloy elements diffused into the γ' phase greater than the amount diffused into the γ phase The amount makes the lattice misfit degree increase in the direction of increase, and the same is true for the test and characterization results.

[0071] Table 2 Lattice constants and mismatch degrees of the γ / γ' phases of the heat-treated samples

[0072] Lattice constants and degrees of mismatch

Embodiment 3

[0074] This method is used to test and characterize the lattice mismatch of the γ / γ' phases in the creep state DD483 single crystal superalloy. The sample is taken from a place 5cm away from the fracture after creep fracture, and the observation surface is perpendicular to the creep tensile stress. , is the (002) plane, the creep condition is 982°C / 250MPa, the test characterization process is the same as that of Example 1, and the test results are shown in Table 3. In the literature Acta Metall Mater 1991; 39:2783-94, the two-phase misfit degree of the (002) plane of the single crystal SRR99 alloy after heat treatment and creep was studied with a twin crystal diffractometer, which changed from -0.14 after heat treatment to after creep. 0.04, its trend of change is consistent with that of the alloy in this example, indicating that the test result of this test method is correct.

[0075] Table 3 Lattice constants and mismatch degrees of γ / γ' phases of creep samples

[0076] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com