Metal composite glasses frame and manufacturing process thereof

A compound glasses and manufacturing process technology, which is applied in the field of spectacle frames, can solve problems such as difficult processing, high overall density, and health hazards of nickel, and achieve the effects of reduced material costs, strong cubic sense, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

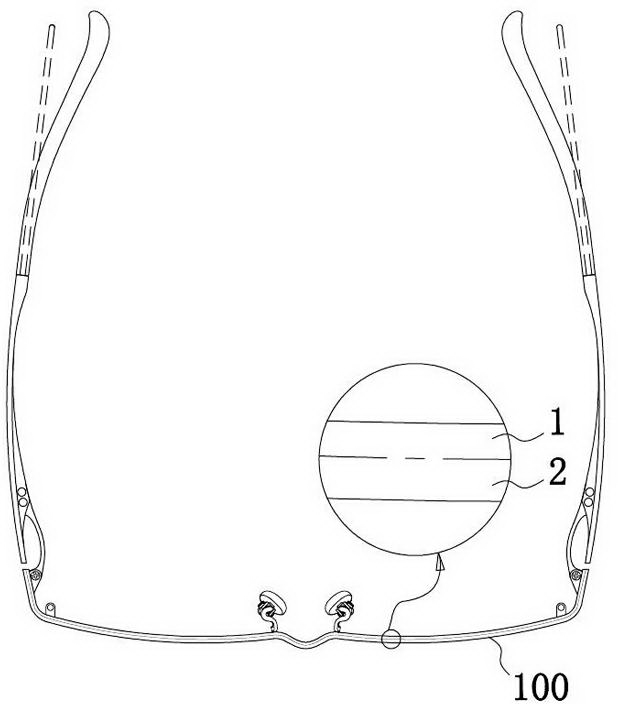

[0015] Such as figure 1 As shown, a metal composite spectacle frame includes a frame body 100, the frame body 100 is composed of double-layer metal layers, and the double-layer metal layers are metal titanium layer 1 and metal aluminum layer 2 sequentially from inside to outside. . The manufacturing process is: select metal aluminum plates with a thickness of 3-4mm and metal titanium plates with a thickness of 0.8-1.2mm, preferably 1mm, to form an aluminum-titanium double-layer metal composite board by welding, and an aluminum-titanium double-layer metal composite board After stamping, cutting, welding, grinding and other processing techniques, it is made into a metal composite spectacle frame with a thickness of 3-5mm, an outer surface made of aluminum, and an inner surface made of titanium. Aluminum is relatively soft, and titanium has high strength and good toughness. Compared with the same all-aluminum spectacle frame, the aluminum-titanium metal composite spectacle fr...

Embodiment 2

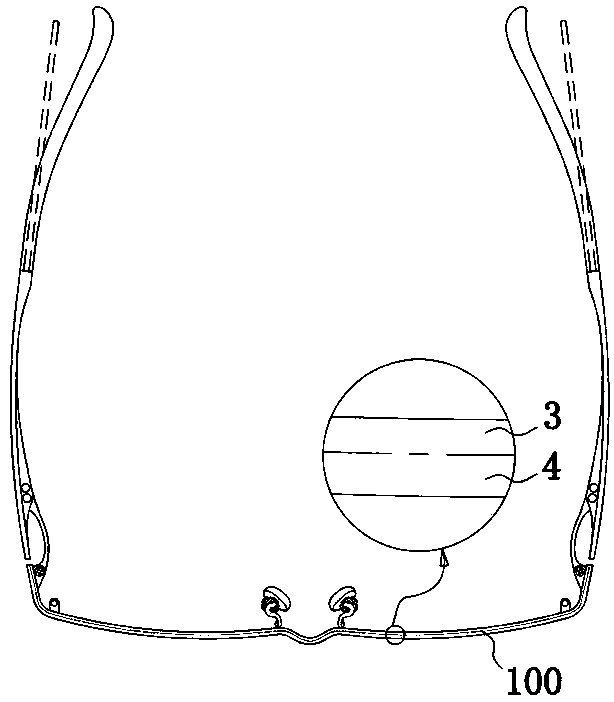

[0017] Such as figure 2 As shown, a metal composite spectacle frame includes a frame body 100. The frame body 100 is composed of double-layer metal layers. The double-layer metal layers are a stainless steel layer 3 and a metal aluminum layer 4 from the inside to the outside. The manufacturing process is: select a metal aluminum plate with a thickness of 3-4mm and a stainless steel plate with a thickness of 0.8-1.2mm, preferably 1 mm, to form a stainless steel-aluminum double-layer metal composite board by welding, and a stainless steel-aluminum double-layer metal composite board After stamping, cutting, welding, grinding and polishing, etc., it is made into a metal composite spectacle frame with a thickness of 3-5mm, an outer surface of aluminum, and an inner surface of stainless steel. Stainless steel has both toughness, elasticity and rigidity, while aluminum is relatively soft. Compared with the same all-aluminum spectacle frame, the strength and hardness of the stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com