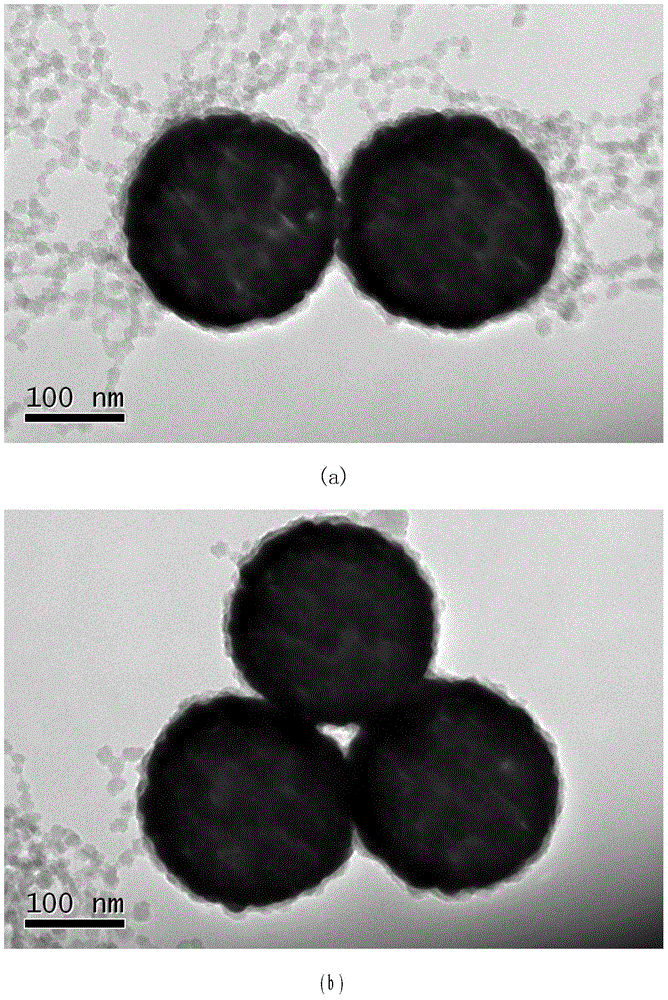

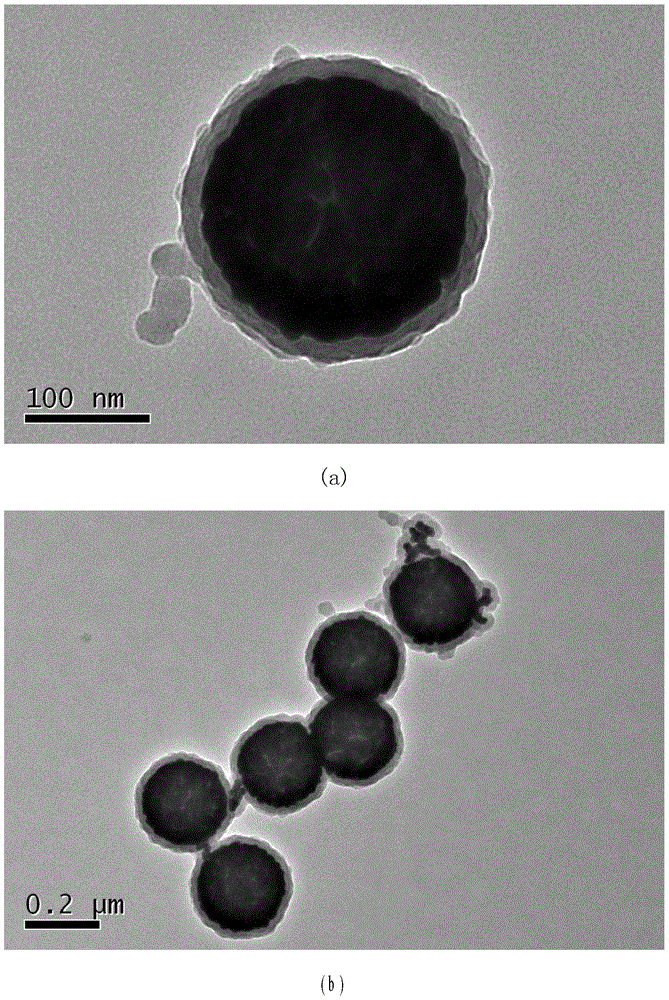

Preparation method of silica/gold/ silica three-layer nano particles

A technology of gold nanoparticles and silicon dioxide, applied in the direction of coating, etc., to achieve the effect of simple experimental equipment, good dispersion, and easy to master the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of silicon dioxide / gold / silicon dioxide three-layer nanoparticles, comprising the following steps:

[0020] 1) Preparation of silica / gold (core / shell) particle solution, comprising the following steps:

[0021] 1.1) Preparation of silica core particles: add 25mL of absolute ethanol to a 50mL conical flask, stir for 10min at a rotating speed of 500r / min, then add 2.5mL of 10% ammonia solution to it, then Stir for 10min, then adjust the speed of the stirrer to 1000r / min, at the same time add 1.1mL of ethyl orthosilicate to it within 5s and stir for 1min, and finally adjust the speed to 500r / min and continue the reaction for 8h;

[0022] 1.2) Amination modification of silica core particles: after the particles obtained in step 1.1) were washed three times with absolute ethanol, they were prepared into 25 mL of ethanol solution, and 20 uL of (3-aminopropyl) trimethoxy was added to the solution. Then, the solution was diluted with ethanol to 125 mL, an...

Embodiment 2

[0030] A preparation method of silicon dioxide / gold / silicon dioxide three-layer nanoparticles, comprising the following steps:

[0031] 1) Preparation of silica / gold (core / shell) particle solution, comprising the following steps:

[0032] 1.1) Preparation of silica core particles: add 25mL of absolute ethanol to a 50mL conical flask, stir for 10min at a rotating speed of 500r / min, then add 2.5mL of 10% ammonia solution to it, then Stir for 10min, then adjust the speed of the stirrer to 1000r / min, at the same time add 1.1mL of ethyl orthosilicate to it within 5s and stir for 1min, and finally adjust the speed to 500r / min and continue the reaction for 8h;

[0033] 1.2) Amination modification of silica core particles: after the particles obtained in step 1.1) were washed three times with absolute ethanol, they were prepared into 25 mL of ethanol solution, and 20 uL of (3-aminopropyl) trimethoxy was added to the solution. Then, the solution was diluted with ethanol to 125 mL, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com