Light-weight assembly-type automobile twist beam suspension

A torsion beam, assembled technology, applied in the field of vehicle engineering, can solve the problems of inconvenient adjustment of torsion beam stiffness, large mass, complex structure, etc., to improve the matching of bending and torsional stiffness characteristics and suspension performance, reduce mass, and ensure strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

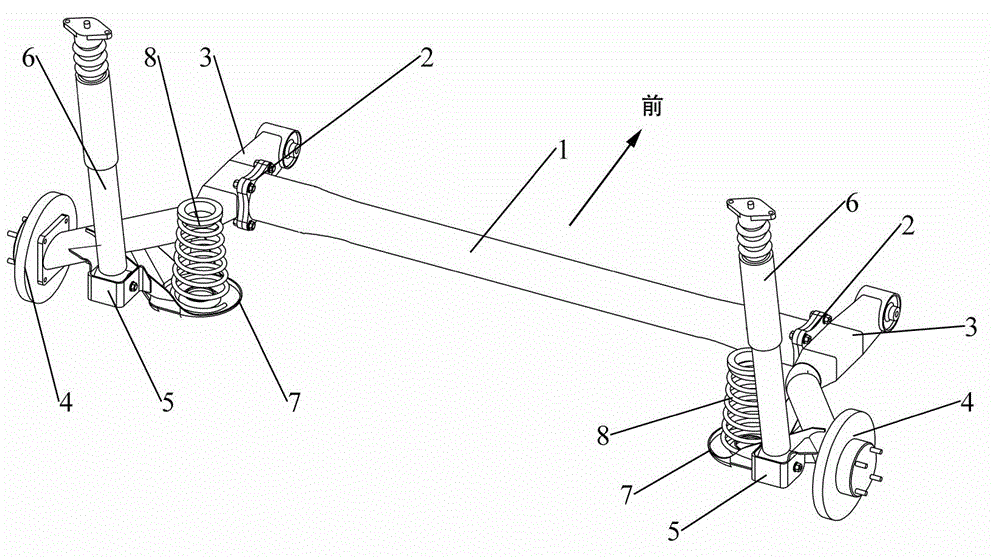

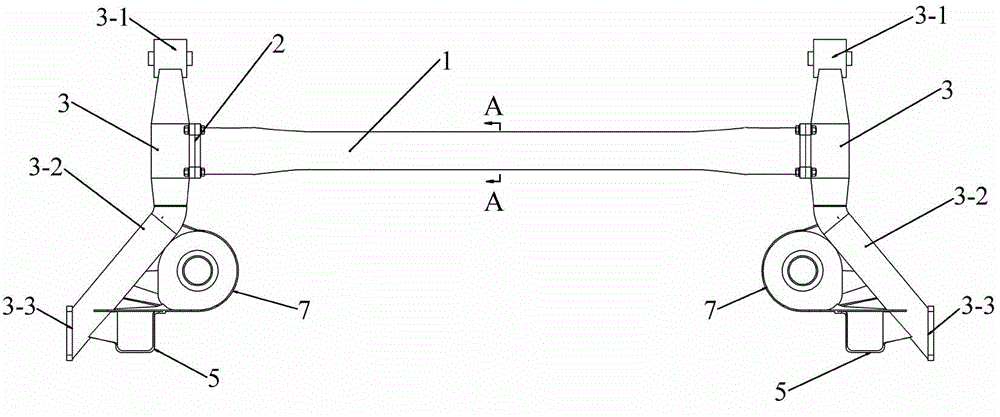

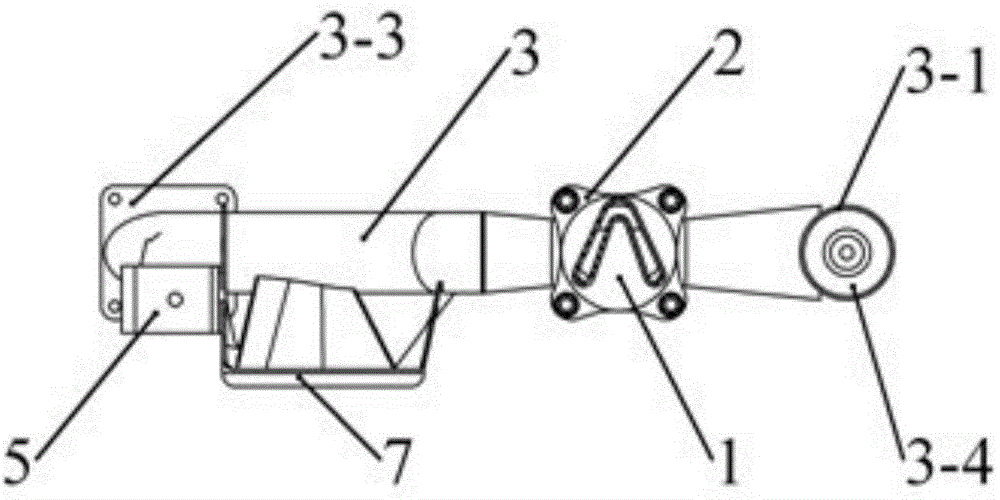

[0028] Specific implementation mode 1. Combination Figure 1 to Figure 11 Illustrate the embodiment of the present invention, a kind of light-weight assembly type automobile torsion beam suspension, by variable section V-shaped tubular torsion beam 1, flange joint 2, suspension trailing arm 3, wheel connection plate 4, shock absorber mounting bracket 5 and a shock absorber 6, a spring seat 7, and a coil spring 8; the V-shaped tubular torsion beam with variable cross-section 1, a flange joint 2, a suspension longitudinal arm 3, a shock absorber mounting bracket 5 and a spring seat 7 are formed The structure is called torsion beam assembly; the suspension longitudinal arms 3 are symmetrically distributed on the left and right sides of the suspension, and extend along the front and rear directions of the vehicle. 2 Connect the suspension longitudinal arm 3 to form an H-shaped structure in which a pair of suspension longitudinal arms 3 are symmetrically connected to both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com