Treatment method for unsymmetrical dimethylhydrazine-containing wastewater

A technology containing unsymmetrical dimethyl hydrazine and a treatment method, which is applied in the field of wastewater treatment, can solve the problems of poor unsymmetrical dimethyl hydrazine sewage effect, constitutes a secondary pollution source, slow reaction speed and the like, and achieves low operating cost and residual ion content. The effect of reducing the concentration and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

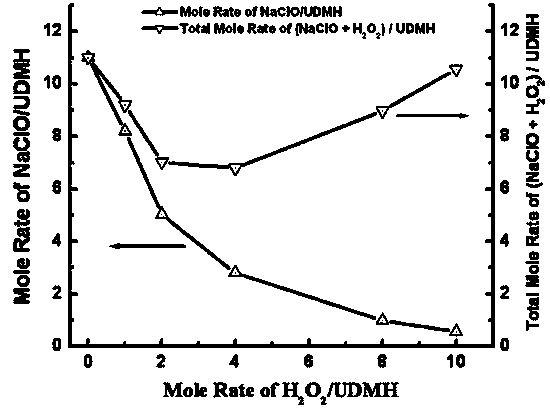

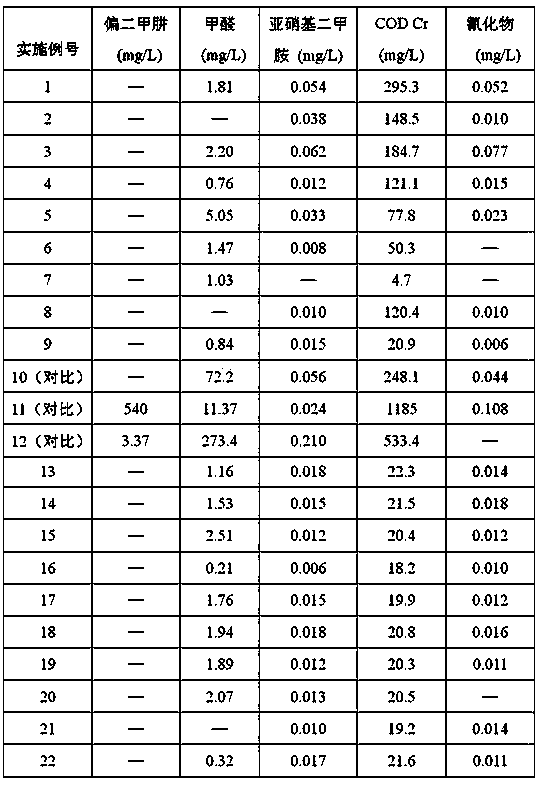

[0027] Take 20mL of unsymmetrical dimethylhydrazine wastewater solution containing 50% mass concentration, add 30wt% H in four times 2 o 2 A total of 113mL, 1g activated carbon supported solid catalyst Fe 2 o 3 , At 20°C, air was introduced at a flow rate of 30L / h. After 8 hours of reaction, the color of the waste liquid was bright yellow. Stop aeration and filter. The solution was 236mL, and the pH value of the solution was always maintained at 7.0-7.5 during the addition process, and the stirring was continued for 30 minutes after the addition was completed. The test results of the water body after the above treatment are listed in Table 1. The gas generated during the reaction process is heated in a 700°C tube furnace, then passed into water for absorption, and then discharged into the atmosphere.

Embodiment 2

[0029] Take 100mL of unsymmetrical dimethylhydrazine wastewater solution containing 10% mass concentration, and add 30wt% H in three times. 2 o 2 A total of 113mL, 0.5g solid catalyst MnO 2 , at 15°C, air was introduced at a flow rate of 40L / h. After 8 hours of reaction, the waste liquid turned bright yellow. Stop aeration and filter. 236mL, keep the pH value of the solution at 7.0-7.5 during the addition process, and continue to stir for 30 minutes after the addition is complete. The water body test results after the above treatment are listed in Table 1. The gas generated during the reaction process is heated in a 700°C tube furnace, then passed into water for absorption, and then discharged into the atmosphere.

Embodiment 3

[0031] Get 100mL of unsymmetrical dimethylhydrazine wastewater solution containing 3% mass concentration, and add 23mL of 30wt% H at one time. 2 o 2 , 0.5g solid catalyst Fe 2 o 3 At 20°C, air was introduced at a flow rate of 40 L / h. After 5 hours of reaction, the waste liquid turned bright yellow. Stop aeration and filter. Chlorine gas was added for 2 minutes, and the pH value of the solution was maintained at 7.0 to 7.5 during the feeding process. After the addition, the stirring was continued for 30 minutes to obtain a clear and transparent solution. The water body test results after the above treatment are listed in Table 1. The gas generated during the reaction is heated in a tube furnace at 500°C, then passed into water for absorption, and then discharged into the atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com