Open-pore polyurethane rigid foam prepared from polyurethane rigid foam degradation liquid

A technology of rigid foam and polyurethane, which is applied in the field of open-cell polyurethane rigid foam, open-cell polyurethane rigid foam and its preparation, and can solve the problems of low density, environmental pollution of waste polyurethane rigid foam, high open cell rate, etc. Achieve the effects of low density, considerable economic benefits, and good sound-absorbing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

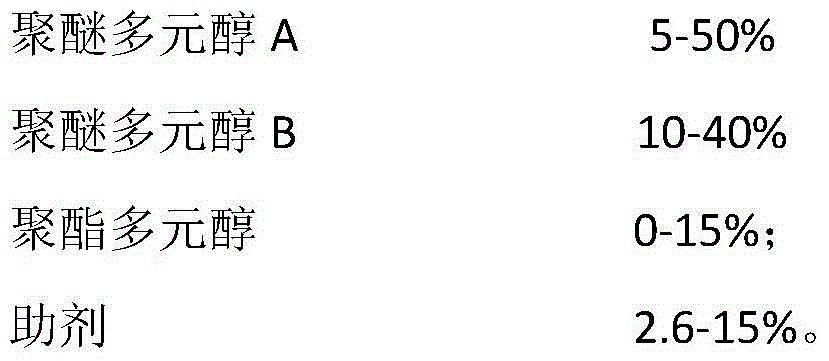

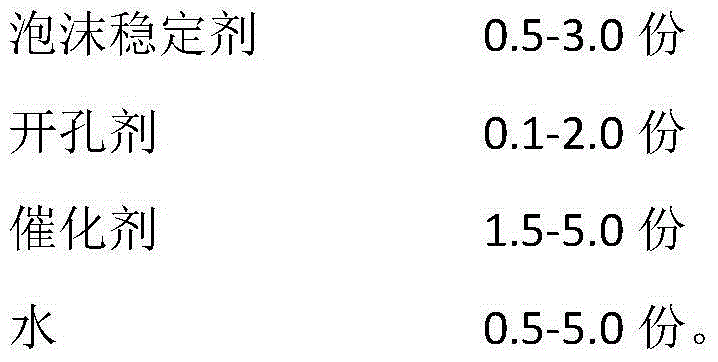

[0031] An open-cell polyurethane rigid foam prepared from a polyurethane rigid foam degradation solution, the formula is as follows:

[0032] Among them, polyurethane rigid foam degradation solution is prepared by reacting butanediol and rigid polyurethane foam under the action of catalyst triethylamine at 150 °C for 12 hours. Its hydroxyl value is 800 mgKOH / g, and its viscosity is 500 mPa·s (25 °C). , polyether polyol A is polyether 330N (Shanghai Gaoqiao), polyether polyol B is H4110III (Nanjing Hongbaoli), polyester polyol PS‐2352 (Stepan)

[0033] Polyurethane rigid foam degradation liquid

10 copies

Polyether Polyol A

45 copies

Polyether Polyol B

35 servings

polyester polyol

10 copies

Tegostab B8433

0.8 servings

O‐501

0.6 parts

Triethylenediamine

0.2 servings

N,N‐Dimethylcyclohexylamine

1.0 servings

Potassium isooctanoate

2.0 servings

0.6 part...

Embodiment 2

[0040] A kind of open cell polyurethane rigid foam prepared by polyurethane rigid foam degradation liquid, formula is as follows:

[0041] Among them, the polyurethane rigid foam degradation solution is prepared by reacting butanediol and rigid polyurethane foam plastics under the action of catalyst sodium hydroxide at 200°C for 6 hours, its hydroxyl value is 760mgKOH / g, and its viscosity is 1500mPa·s (25°C) , polyether polyol A is polyether 330N (Shandong Dongda), polyether polyol B is H6035 (Nanjing Hongbaoli)

[0042] Polyurethane rigid foam degradation liquid

20 servings

Polyether Polyol A

40 servings

Polyether Polyol B

40 servings

Tegostab B8444

0.80 servings

O‐501

0.50 servings

Pentamethyldiethylenetriamine

0.20 servings

N,N‐Dimethylcyclohexylamine

1.0 servings

Potassium isooctanoate

1.6 servings

0.6 parts

water

1.0 servings

Isopentane ...

Embodiment 3

[0048] A kind of open cell polyurethane rigid foam prepared by polyurethane rigid foam degradation liquid, formula is as follows:

[0049] Among them, the polyurethane rigid foam degradation solution is prepared by reacting butanediol and rigid polyurethane foam plastics under the action of catalyst potassium hydroxide at 150°C for 8 hours, its hydroxyl value is 710mgKOH / g, and its viscosity is 2500mPa·s (25°C) , polyether polyol A is polyether H6000 (Nanjing Hongbaoli), polyether polyol B is H4110III (Nanjing Hongbaoli)

[0050] Polyurethane rigid foam degradation liquid

25 servings

Polyether Polyol A

40 servings

Polyether Polyol B

35 servings

Tegostab B8466

1.2 parts

K757

0.6 parts

Triethylenediamine

0.2 servings

N,N‐Dimethylcyclohexylamine

1.0 servings

Potassium isooctanoate

2.0 servings

0.6 parts

water

1.5 servings

10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com