Sponge and preparation method thereof

A technology of sponge and polyurethane sponge, applied in the field of sponge and its preparation, can solve the problems of easy to feel heat, poor air permeability and water permeability, damage to human health, etc. , The effect of saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

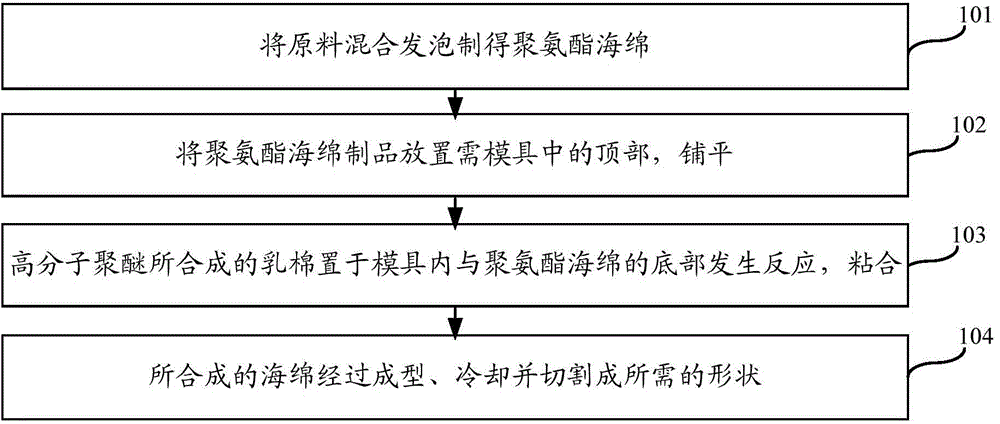

[0033] The preparation method of sponge is as follows:

[0034] (A) In terms of parts by mass, 45 parts of toluene diisocyanate, 2.5 parts of water and 1 part of foaming agent are mixed and foamed to obtain a polyurethane sponge;

[0035] (B) 25 parts of diisocyanate, 1.5 parts of water, 1 part of polymerization catalyst, 45 parts of polyether polyol and 3 parts of flame retardant were mixed and stirred evenly to obtain the first mixture;

[0036] (C) Fix the polyurethane sponge on the top of the mould, put the first mixture in the mold and mix and foam with 2 parts of foaming agent to form the foam, after making the foam and the polyurethane foam polymerize, after molding, cooling and The cutting step yields the product.

Embodiment 2

[0038] The preparation method of sponge is as follows:

[0039] (A) In terms of parts by mass, 60 parts of toluene diisocyanate in the raw material, 3 parts of water and 2 parts of foaming agent are mixed and foamed to obtain a polyurethane sponge, and the density of the polyurethane sponge obtained is 18kg / m 3 ;

[0040] (B) 35 parts of diisocyanate, 3 parts of water, 2 parts of stannous octoate, 60 parts of polyether polyol and 4 parts of polyhydroxy reactive flame retardant in the raw material are placed in a room with a temperature of 25 ° C and a relative humidity greater than 35%. Under the conditions, the first mixture was obtained after mixing and stirring for 2 minutes, and the stirring rate was 200rad / min;

[0041] (C) Fix the polyurethane sponge on the top of the mold, put the first mixture in the mold and mix and foam with 2 parts of the foaming agent to form the foam, then make the foam and the polyurethane sponge polymerize for 2-3 minutes, when the polymerizati...

Embodiment 3

[0043] The preparation method of sponge is as follows:

[0044] (A) In terms of parts by mass, 50 parts of toluene diisocyanate in the raw material, 3 parts of water and 1 part of blowing agent are mixed and foamed to obtain a polyurethane sponge, and the density of the polyurethane sponge obtained is 20kg / m 3 ;

[0045] (B) 30 parts of diisocyanate, 2 parts of water, 1.5 parts of triethylenediamine, 50 parts of polyether polyol and 3.5 parts of a mixture of polyhydroxyl reactive flame retardant and halogen-free flame retardant in the raw material were heated at a temperature of 50°C, under the condition that the relative humidity is greater than 35%, the first mixture is obtained after mixing and stirring for 3 minutes, and the stirring rate is 100rad / min;

[0046](C) Fix the polyurethane sponge on the top of the mold, put the first mixture in the mold and mix and foam with 2 parts of the foaming agent to form the foam, then make the foam and the polyurethane sponge polymeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com