Graphite carbon fiber composite conductive filler for grounding module and its preparation method and application

A grounding module and fiber composite technology, which is applied in the direction of connecting contact materials, etc., can solve the problems of low grounding resistance reduction effect, difficult soil contact and high surface hardness, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

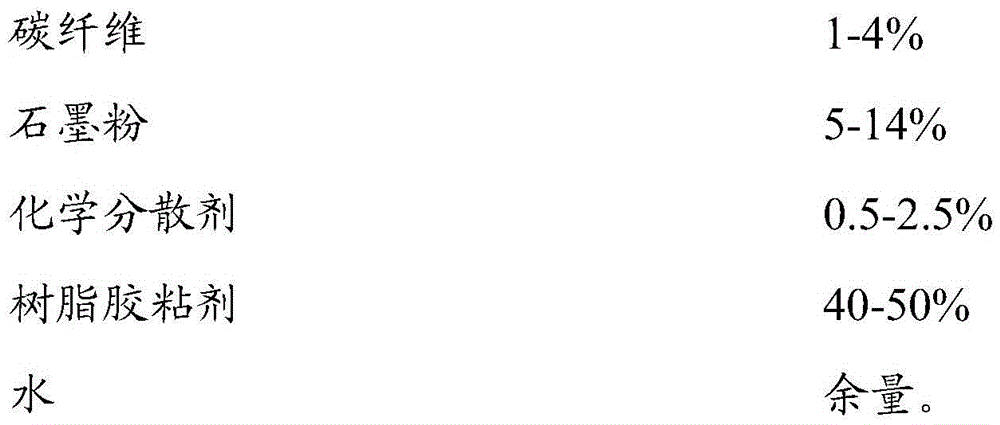

[0034] In this embodiment, a graphite carbon fiber composite conductive filler for a grounding module is prepared from the following raw materials in weight percentage:

[0035]

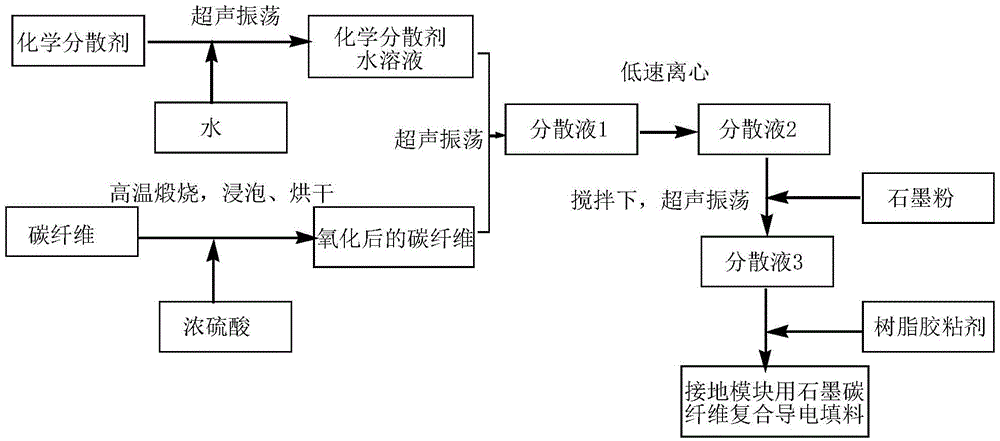

[0036] The preparation method of graphite carbon fiber composite conductive filler for above-mentioned grounding module comprises the following steps (such as figure 1 shown):

[0037] Calcining the carbon fibers at a high temperature of 300°C for 30 minutes, soaking in concentrated sulfuric acid for 4 hours, washing and drying to obtain oxidized carbon fibers;

[0038] Add the chemical dispersant in water, ultrasonically oscillate and disperse, then add the oxidized carbon fiber, ultrasonically oscillate and disperse to obtain dispersion 1;

[0039] After the dispersion 1 was centrifuged at 1500r / min at a low speed for 0.5h, the upper layer liquid was taken to obtain the dispersion 2;

[0040] Add the graphite powder into the dispersion 2, and disperse with ultrasonic vibration under stirring t...

Embodiment 2

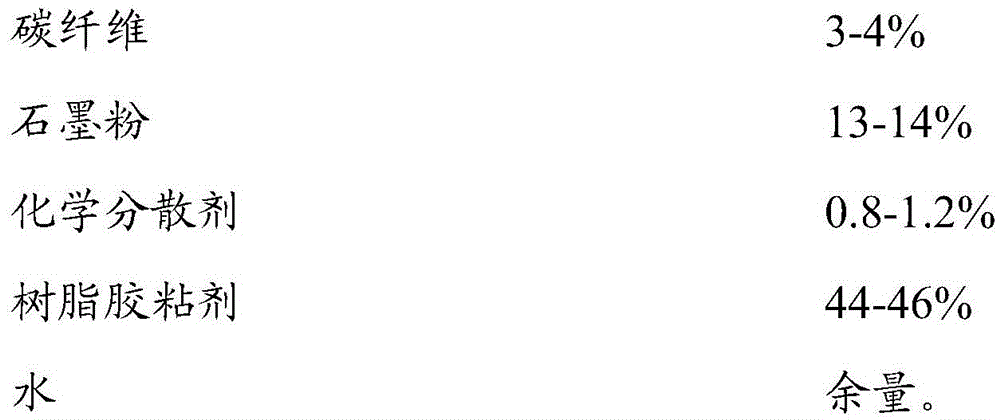

[0044] In this embodiment, a graphite carbon fiber composite conductive filler for a grounding module is prepared from the following raw materials in weight percentage:

[0045]

[0046] The preparation method of the graphite carbon fiber composite conductive filler for the above-mentioned grounding module comprises the following steps:

[0047] Calcining the carbon fibers at a high temperature of 250°C for 20 minutes, soaking in concentrated sulfuric acid for 3 hours, washing and drying to obtain oxidized carbon fibers;

[0048] Add the chemical dispersant in water, ultrasonically oscillate and disperse, then add the oxidized carbon fiber, ultrasonically oscillate and disperse to obtain dispersion 1;

[0049] After the dispersion 1 was centrifuged at 1000r / min at low speed for 0.1h, the upper layer liquid was taken to obtain the dispersion 2;

[0050] Add the graphite powder into the dispersion 2, and disperse with ultrasonic vibration under stirring to obtain the dispers...

Embodiment 3

[0053] In this embodiment, a graphite carbon fiber composite conductive filler for a grounding module is prepared from the following raw materials in weight percentage:

[0054]

[0055] The preparation method of the graphite carbon fiber composite conductive filler for the above-mentioned grounding module comprises the following steps:

[0056] Calcining the carbon fibers at a high temperature of 350°C for 40 minutes, soaking in concentrated sulfuric acid for 5 hours, washing and drying to obtain oxidized carbon fibers;

[0057] Add the chemical dispersant in water, ultrasonically oscillate and disperse, then add the oxidized carbon fiber, ultrasonically oscillate and disperse to obtain dispersion 1;

[0058] After the dispersion 1 was centrifuged at 2000r / min at a low speed for 1h, the upper layer liquid was taken to obtain the dispersion 2;

[0059] Add the graphite powder into the dispersion 2, and disperse with ultrasonic vibration under stirring to obtain the dispersio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com