A kind of preparation method of glass fiber reinforced polyamide composite material loaded with nucleating agent

A glass fiber and composite material technology, which is applied in the field of glass fiber reinforced polyamide composite materials, can solve the problems of insignificant effect and destroy polymer crystallization, and achieve the effect of simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation concentration is the 1.24L clay suspension of 2g / L, after stirring evenly, add the circular glass fiber that concentration is 200g / L, utilize the electrostatic adsorption between glass fiber and clay, obtain the glass fiber reinforcement that surface is adsorbed with clay. body; the above-mentioned glass fiber reinforced body and polyamide 66 are compounded by extrusion molding process to obtain a clay-loaded glass fiber reinforced polyamide composite material, which contains 10% glass fiber reinforced body.

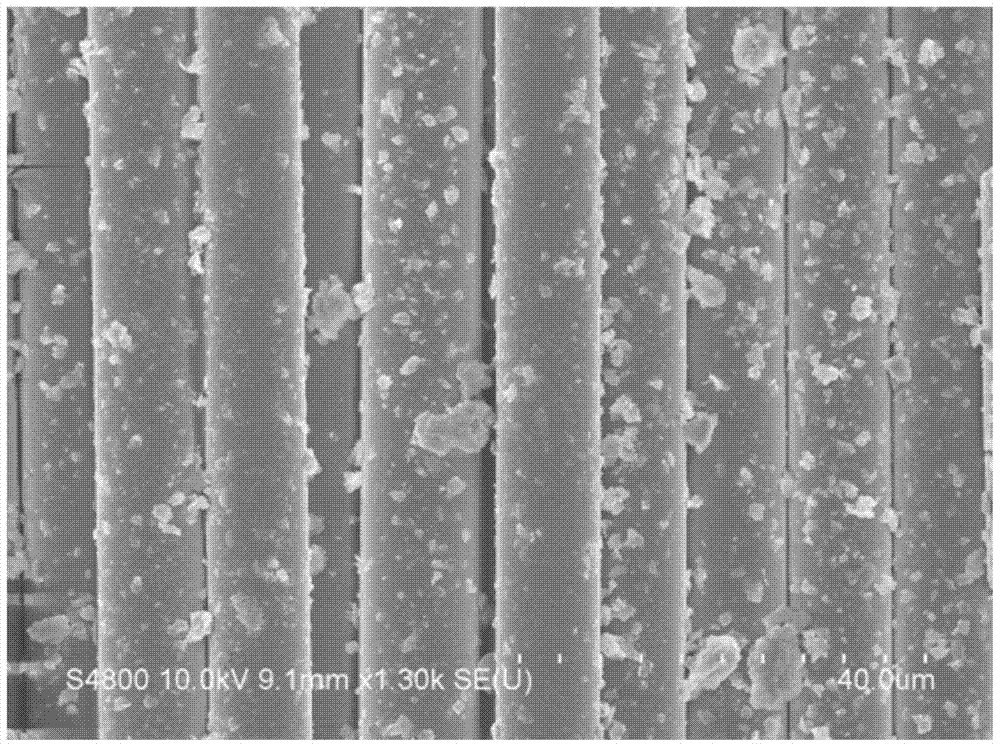

[0028] figure 1 It is the scanning electron micrograph of the glass fiber reinforced body prepared when the concentration of 1.24L clay suspension is 2g / L; figure 2 The scanning electron micrograph of the interlaminar shear section of the glass fiber reinforced polyamide 66 composite material prepared when the concentration of 1.24L clay suspension is 2g / L.

Embodiment 2

[0030] Prepare BRUGGOLEN P22 organic nucleating agent suspension with a concentration of 2g / L, stir evenly, add round glass fibers with a concentration of 200g / L, and use the electrostatic adsorption between the round glass fibers and the organic nucleating agent to obtain a surface A glass fiber reinforced body that absorbs an organic nucleating agent; compound the above glass fiber reinforced body and polyamide 66 through an extrusion molding process to obtain a glass fiber reinforced polyamide composite material loaded with an organic nucleating agent, and the composite material contains 10% Glass fiber reinforcement.

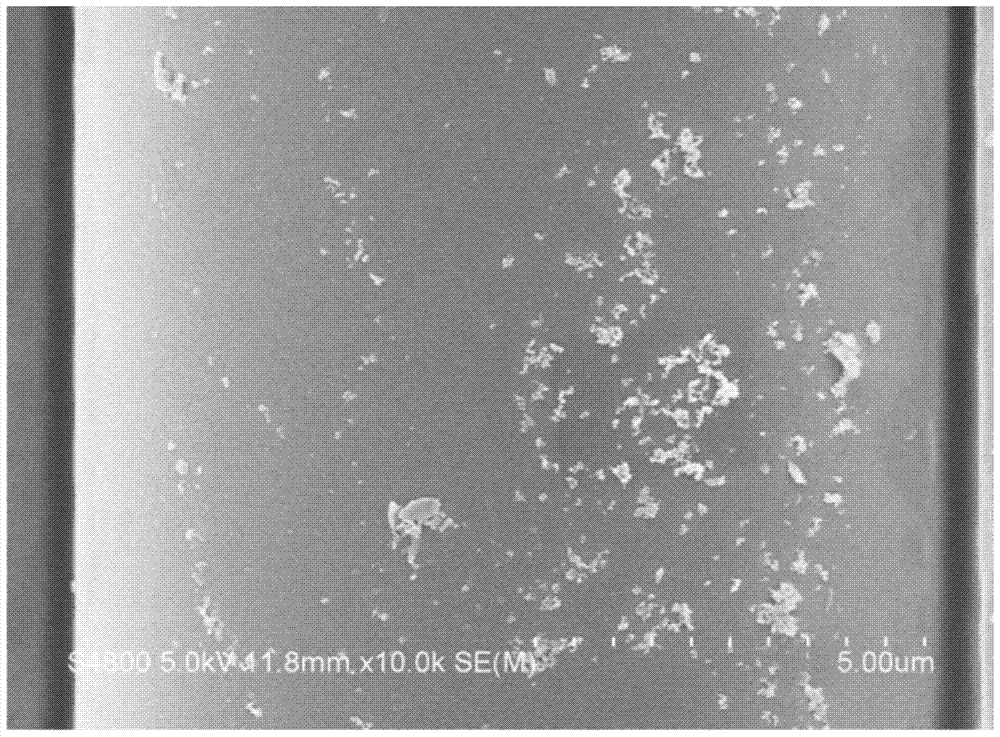

[0031] image 3 The scanning electron micrograph of the circular short glass fiber reinforcement loaded with organic nucleating agent prepared when the concentration of BRUGGOLEN P22 organic nucleating agent suspension is 2g / L.

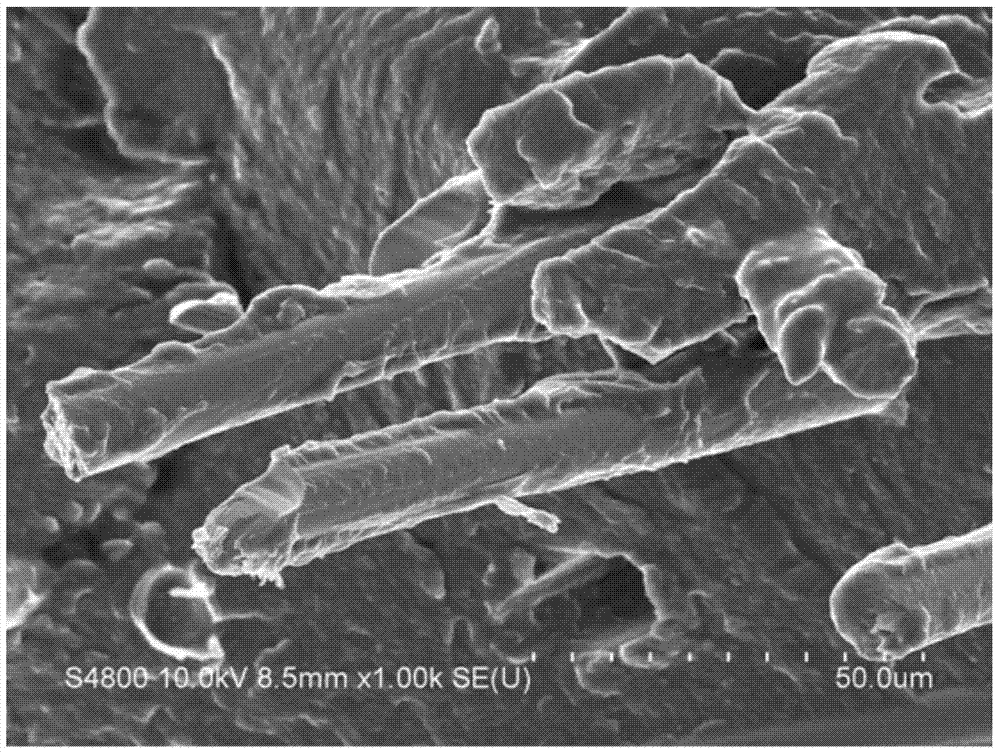

[0032] Figure 4 Scanning electron micrograph of the interlayer shear section of the circular short glass fiber reinforced polya...

Embodiment 3

[0042]Prepare the I.44P clay suspension with a concentration of 2g / L, stir evenly and add flat glass fibers with a concentration of 200g / L, and use the electrostatic adsorption between the flat glass fibers and the clay to obtain flat glass fibers with clay adsorbed on the surface Reinforcement: Composite the above glass fiber reinforcement and polyamide 66 through an extrusion molding process to obtain a clay-loaded flat glass fiber reinforced polyamide composite material, which contains 10% flat glass fiber reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com